A high temperature resistant carbon dioxide hydrogenation methanol synthesis catalyst and its preparation and application

A technology for carbon dioxide and methanol synthesis, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, hydroxyl compound preparation, etc. Good sintering performance, no decrease in space-time yield, and the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

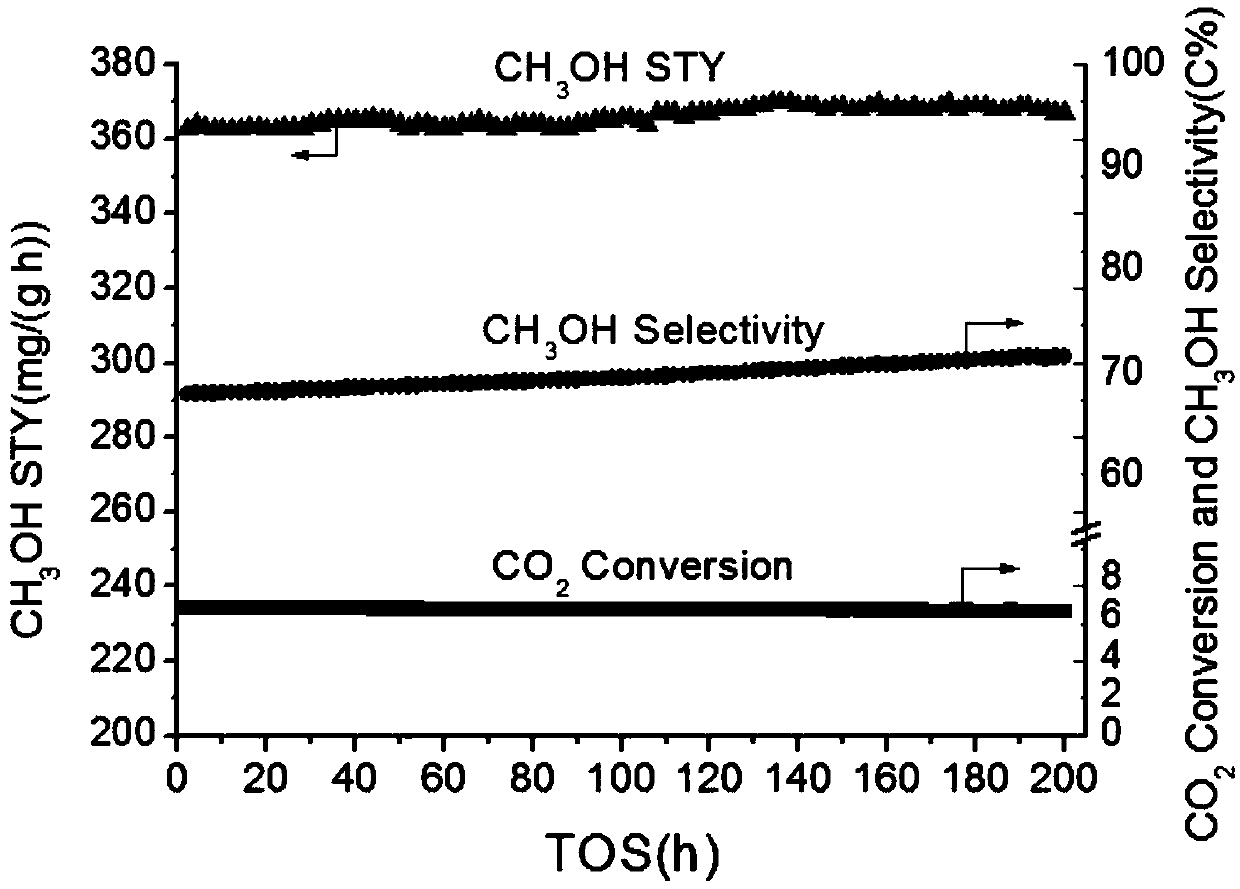

Examples

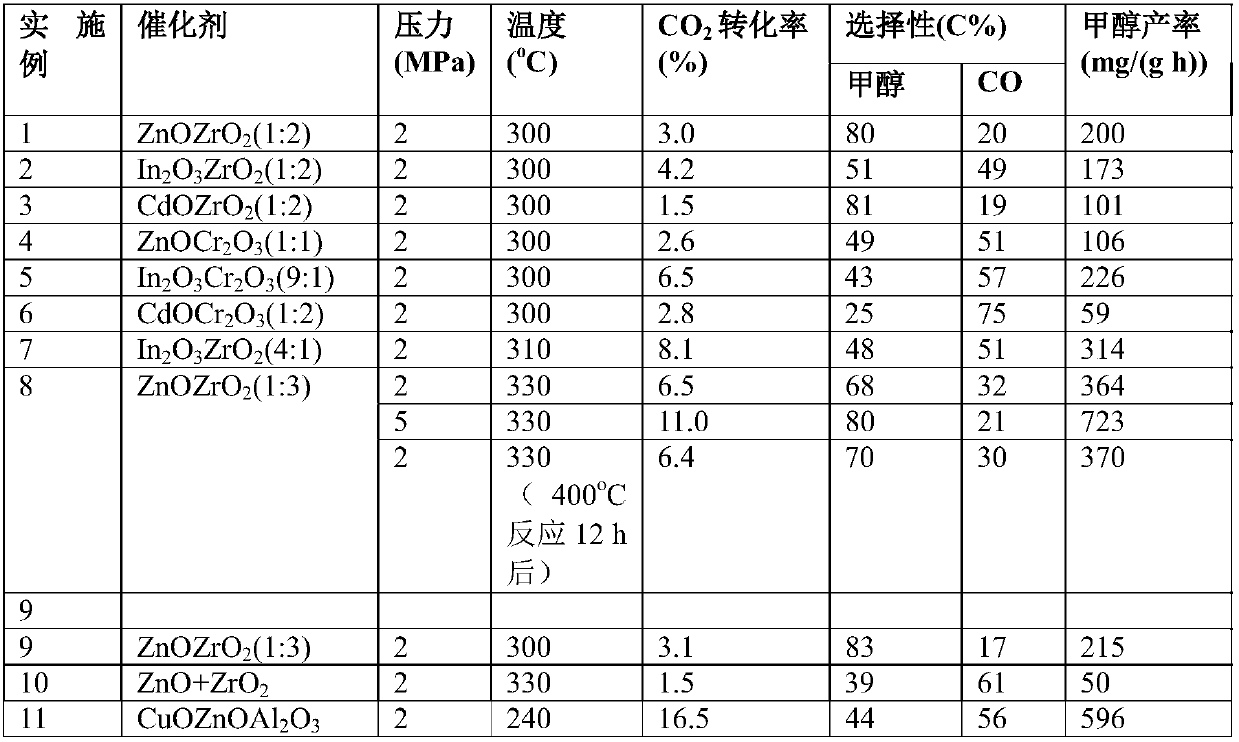

Embodiment 1

[0013] Weigh 5mmol Zn(NO 3 ) 2 ·6H 2 O, 10mmol Zr(NO 3 ) 4 ·5H 2 O is configured into 100mL aqueous solution and placed in a 500mL beaker, weigh 27.5mmol (NH 4 ) 2 CO 3 Configured into 100mL aqueous solution, at 70℃, stirring speed 600r / min, the prepared (NH 4 ) 2 CO 3 The solution is dropped into the metal salt solution, the dropping rate is about 3mL / min, and the (NH 4 ) 2 CO 3 After the solution is consumed, the resulting precipitation mother liquor is aged for 2 hours at 70°C, cooled, filtered naturally, washed 3 times with deionized water, filtered with suction, dried at 60°C, and calcined in air at 500°C for 3 hours to obtain the catalyst oxidation state precursor. Tablets were pressed at 10MPa, crushed, and screened from 40 to 80 meshes for evaluation.

[0014] Weigh 0.15g of the selected catalyst into a reaction tube with an inner diameter of 6mm. 2 Reduce at 300℃ for 2h at a flow rate of 30mL / min, and then introduce feed gas n(H 2 ):n(CO 2 )=3, the reaction was carried out...

Embodiment 2

[0016] The metal salt used in the preparation of the catalyst is 5mmol In(NO 3 ) 3 ·5H 2 O, 10mmol Zr(NO 3 ) 4 ·5H 2 O, the precipitant used is 30.3mmol(NH 4 ) 2 CO 3 . Other preparation and evaluation steps are the same as in Example 1, and the catalyst evaluation results are shown in Table 1.

Embodiment 3

[0018] The metal salt used in the preparation of the catalyst is 5mmol Cd(NO 3 ) 2 ·4H 2 O, 10mmol Zr(NO 3 ) 4 ·5H 2 O, the precipitant used is 27.5mmol (NH 4 ) 2 CO 3 . Other preparation and evaluation steps are the same as in Example 1, and the catalyst evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com