A core-shell catalyst for selective hydrodeoxygenation of guaiacol to cyclohexanol

A core-shell structure, guaiacol technology, applied in the direction of physical/chemical process catalysts, hydrogenation preparation, chemical instruments and methods, etc., can solve the problem of short service life of catalysts, low selectivity of reaction products, and easy oxidation of oxygen-containing compounds. Polymerization and other problems, to achieve the effect of good anti-sintering performance, good selectivity of the target product, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Weigh 7g Ni(NO 3 ) 2 x6 2 O, dissolve it in 700ml of ethanol aqueous solution (volume ratio of alcohol to water: 4:3), add 1g of polyvinylpyrrolidone (PVP) as a stabilizer, and stir well. Then, under stirring condition, 140ml of 25% ammonia water was added dropwise and left for 10min.

[0027] Step 2: Weigh 6g of surfactant cetyltrimethylammonium bromide (CTAB), add it into the above solution, stir evenly, and let stand for 10min. Then measure 20ml of tetraethyl orthosilicate (TEOS), and add it dropwise into the solution under stirring condition. Place it at room temperature for 48 hours.

[0028] Step 3: Filter out the precipitate, wash it with deionized water, dry it in an oven at 60°C for 12 hours, grind it after the end, calcinate it in a muffle furnace at 500°C for 6 hours, and finally reduce it in a hydrogen atmosphere at 550°C for 6 hours to obtain 20 %Ni@SiO 2 Core-shell catalysts.

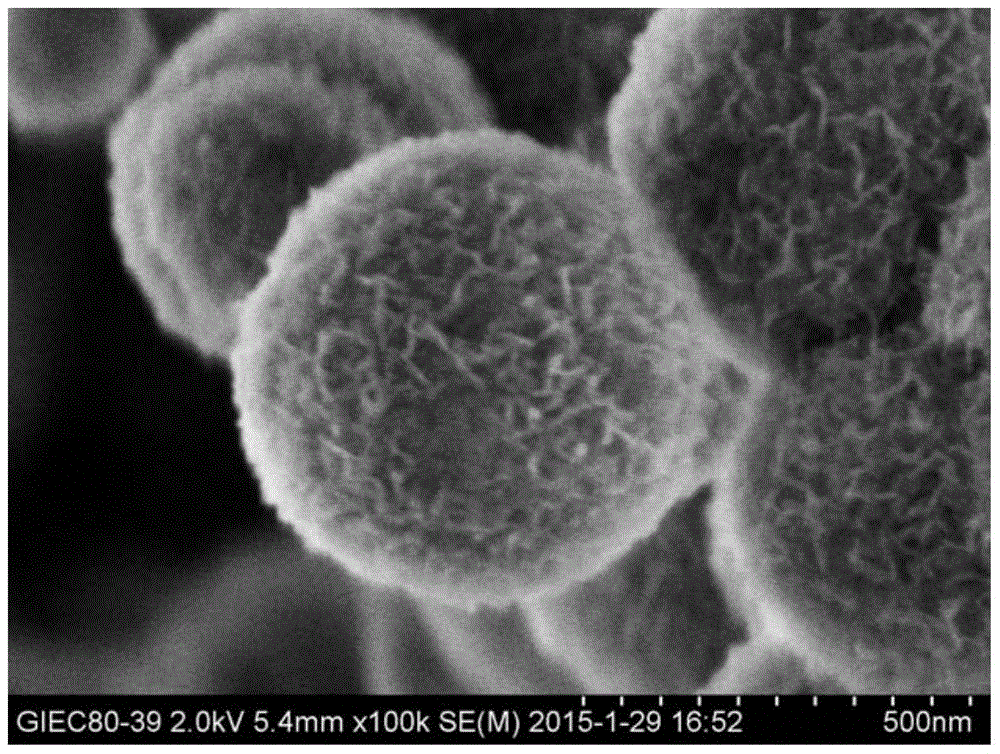

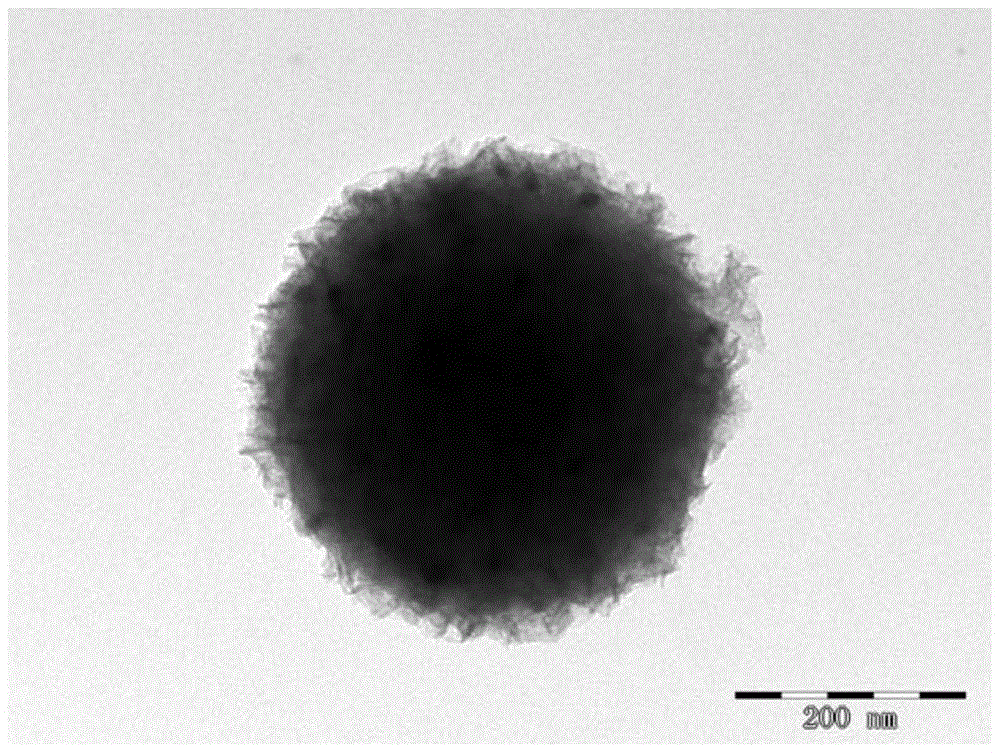

[0029] 20%Ni@SiO 2 SEM and TEM images of core-shell catalysts c...

Embodiment 2

[0036] Step 1: Weigh 10.5g Ni(NO 3 ) 2 x6 2 O, dissolve it in 1000ml of ethanol aqueous solution (volume ratio of alcohol to water: 1:1), add 2g of polyvinylpyrrolidone (PVP) as a stabilizer, and stir well. Then, under stirring condition, 210ml of 25% ammonia water was added dropwise and left for 10min.

[0037] Step 2: Weigh 9g of surfactant cetyltrimethylammonium bromide (CTAB), add it to the above solution, stir evenly, and let stand for 10min. Then measure 30ml of tetraethyl orthosilicate (TEOS), and add it dropwise into the solution under stirring condition. Place it at room temperature for 48 hours.

[0038] Step 3: Filter out the precipitate, wash it with deionized water, dry it in an oven at 60°C for 12 hours, grind it after the end, calcinate it in a muffle furnace at 500°C for 4 hours, and finally reduce it in a hydrogen atmosphere at 550°C for 4 hours to obtain 20 %Ni@SiO 2 Core-shell catalysts.

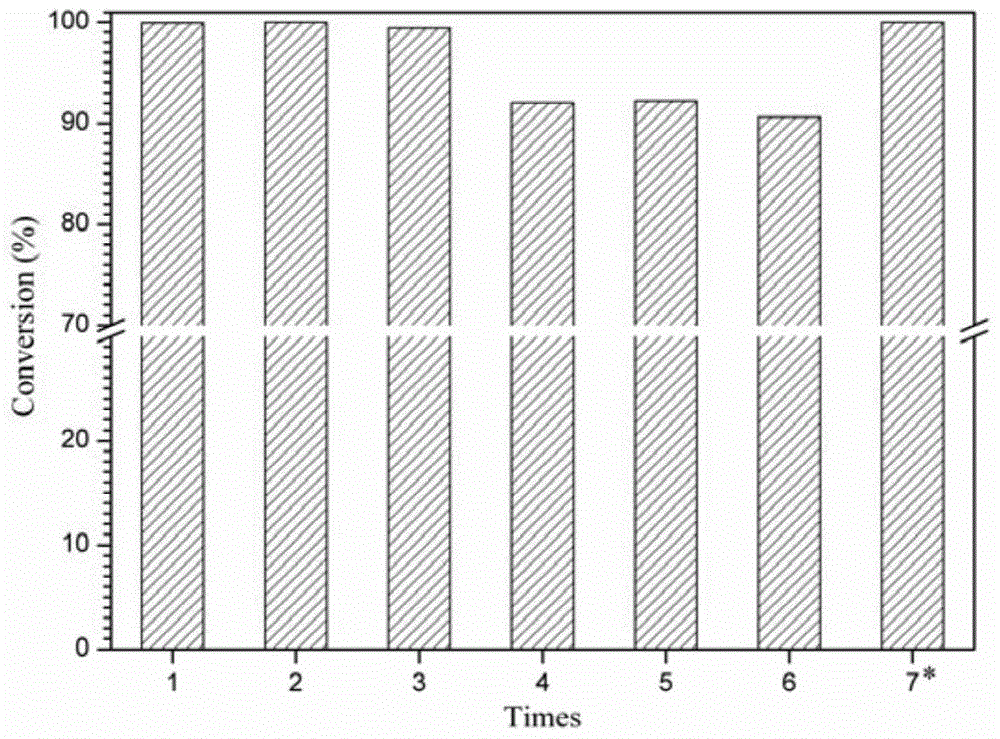

[0039]Evaluation of catalytic performance: Add 20ml of decahyd...

Embodiment 3

[0043] Step 1: Weigh 4.6g Ni(CH 3 COO) 2 4H 2 O, dissolve it in 700ml of ethanol aqueous solution (volume ratio of alcohol to water: 4:3), add 1g of polyvinylpyrrolidone (PVP) as a stabilizer, and stir well. Then, under stirring condition, 100 ml of 25% ammonia water was added dropwise and left for 10 min.

[0044] Step 2: Weigh 6 g of cetyltrimethylammonium bromide (CTAB) as a surfactant, add it to the above solution, stir evenly, and let stand for 10 minutes. Then measure 20ml of tetraethyl orthosilicate (TEOS), and add it dropwise into the solution under stirring condition. Place it at room temperature for 48 hours.

[0045] Step 3: Filter out the precipitate, wash it with deionized water, dry it in an oven at 60°C for 12 hours, grind it after the end, calcinate it in a muffle furnace at 500°C for 6 hours, and finally reduce it in a hydrogen atmosphere at 550°C for 6 hours to obtain 15 %Ni@SiO 2 Core-shell catalysts.

[0046] Evaluation of catalytic performance: Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com