Abrasive particle monitoring sensor of oil

A technology for monitoring sensors and oil abrasive particles, which is used in measuring devices, particle size analysis, scientific instruments, etc., can solve problems such as poor monitoring results, and achieve reduced sensor size, strong anti-interference ability, non-contact measurement and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific examples and with reference to the accompanying drawings.

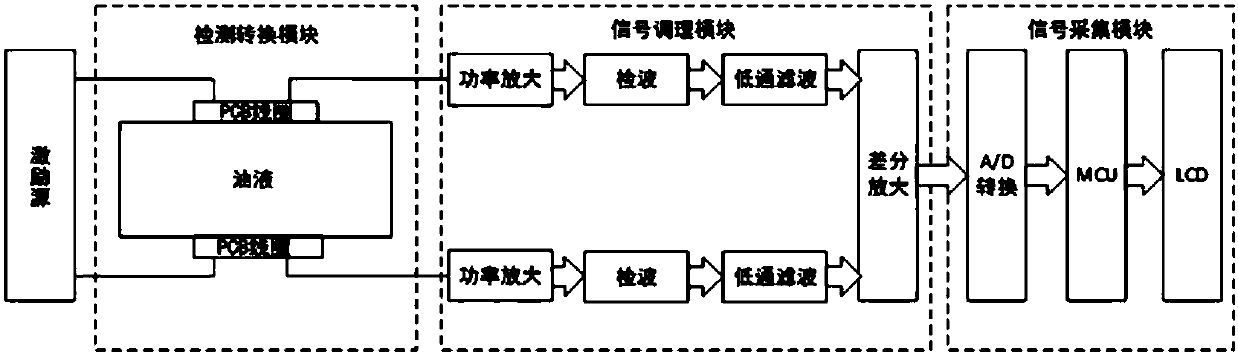

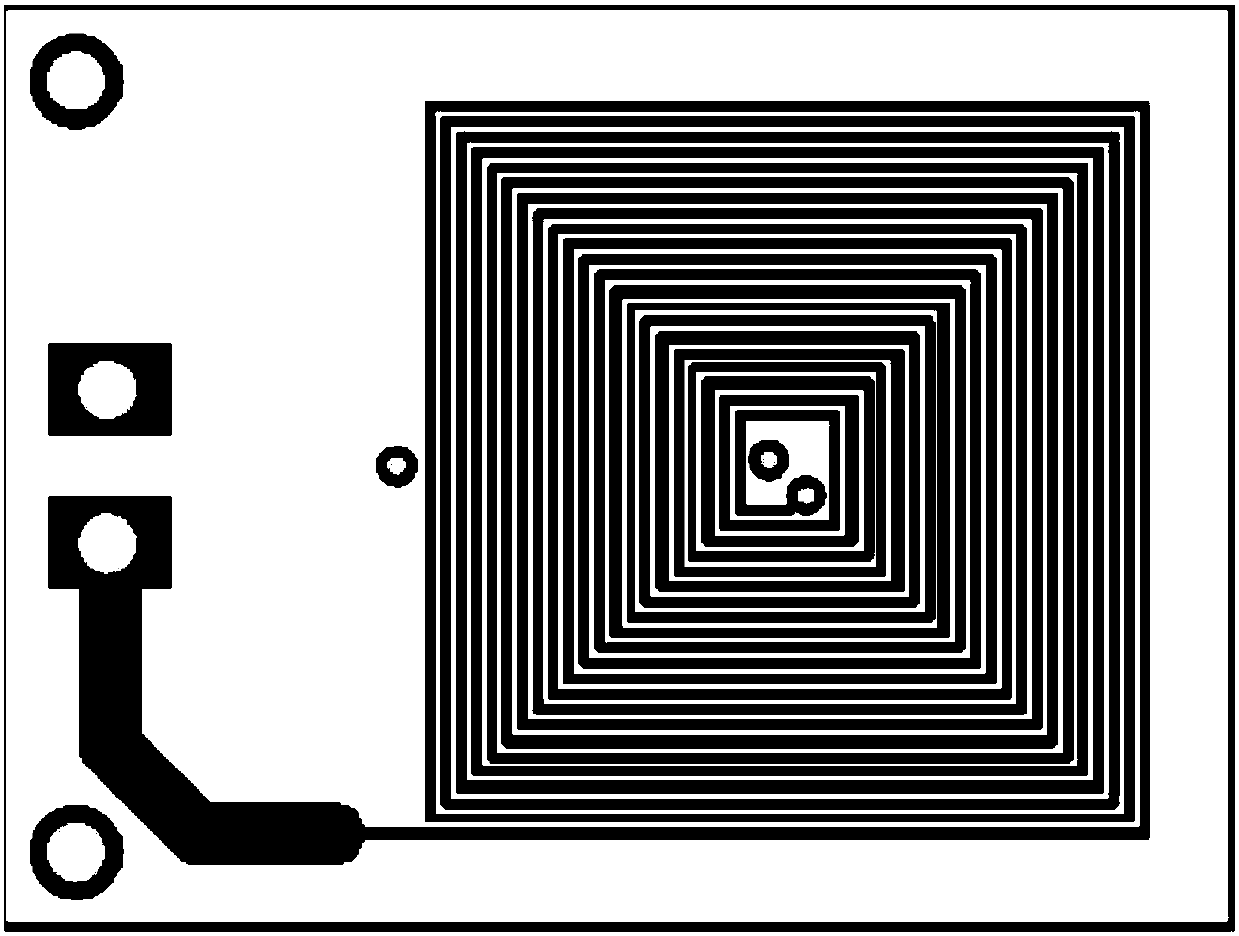

[0021] An oil wear particle monitoring sensor such as figure 1 As shown, it is mainly composed of excitation source, detection conversion module, signal conditioning module and signal acquisition module.

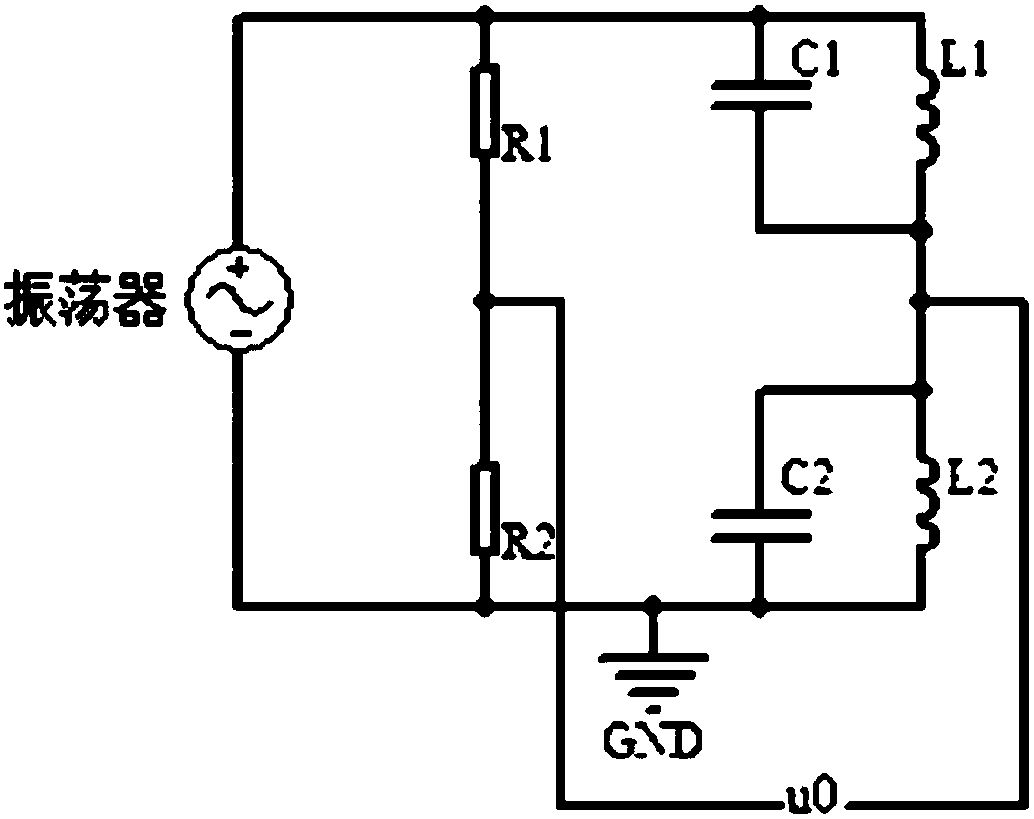

[0022] The above-mentioned excitation source is a sinusoidal signal generator with controllable frequency. The sensitivity of the sensor can be adjusted by controlling the frequency of the excitation source. The excitation frequency can be selected according to the diameter of the oil pipe. High-frequency excitation can obtain better sensitivity when the pipe diameter is small. When the liquid pipe diameter is large, low-frequency excitation can be used to obtain better sensitivity, and the specific parameters are adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com