Dynamic-static optimization method of milling stability of numerical control machine tool

A technology of milling processing and CNC machine tools, which is applied in the direction of program control, computer control, general control system, etc., can solve problems such as less obvious effects, and achieve the effect of improving processing effect and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

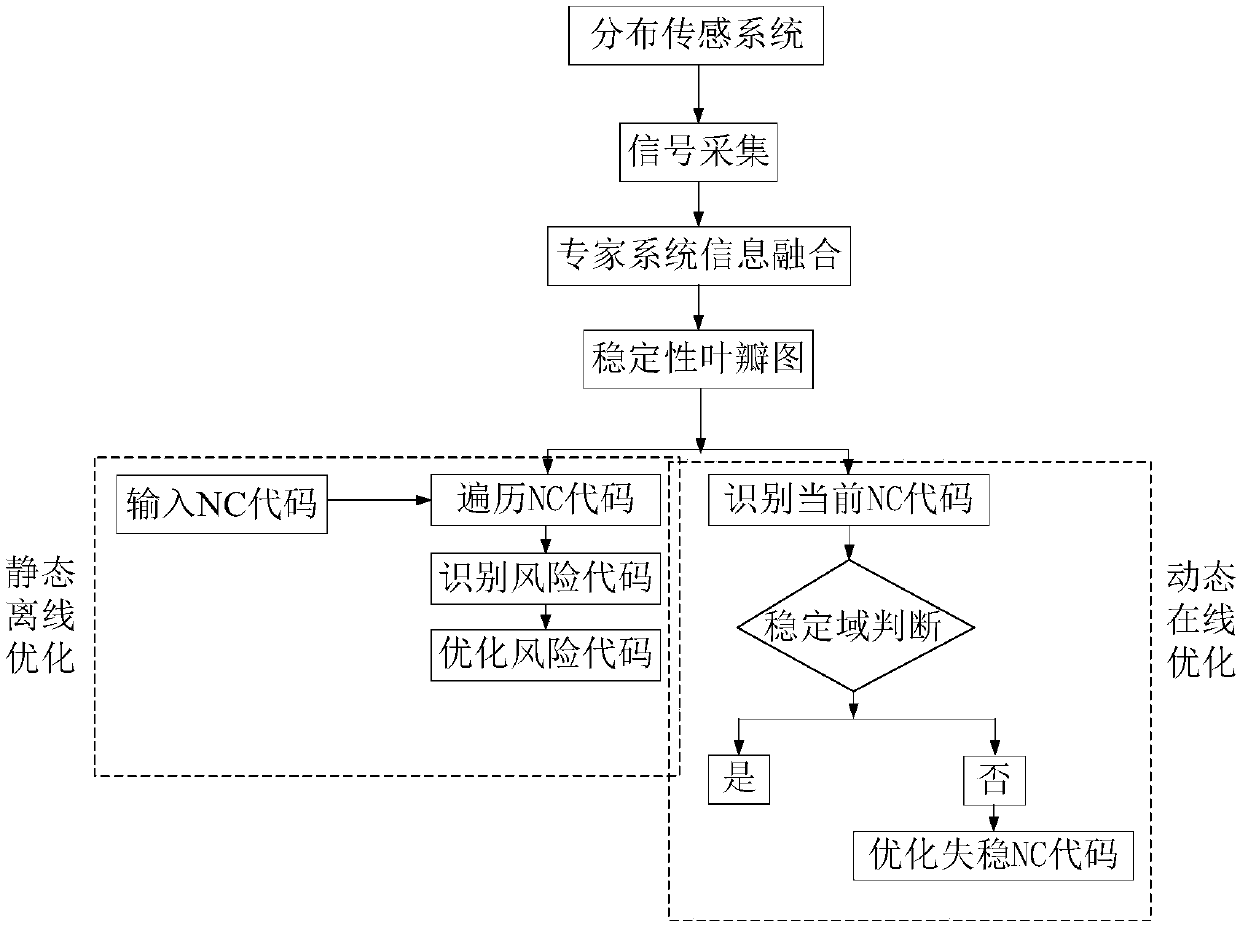

[0044] Such as Figure 1-7 As shown, a dynamic-static optimization method for the stability of CNC machine tool milling, including the following steps:

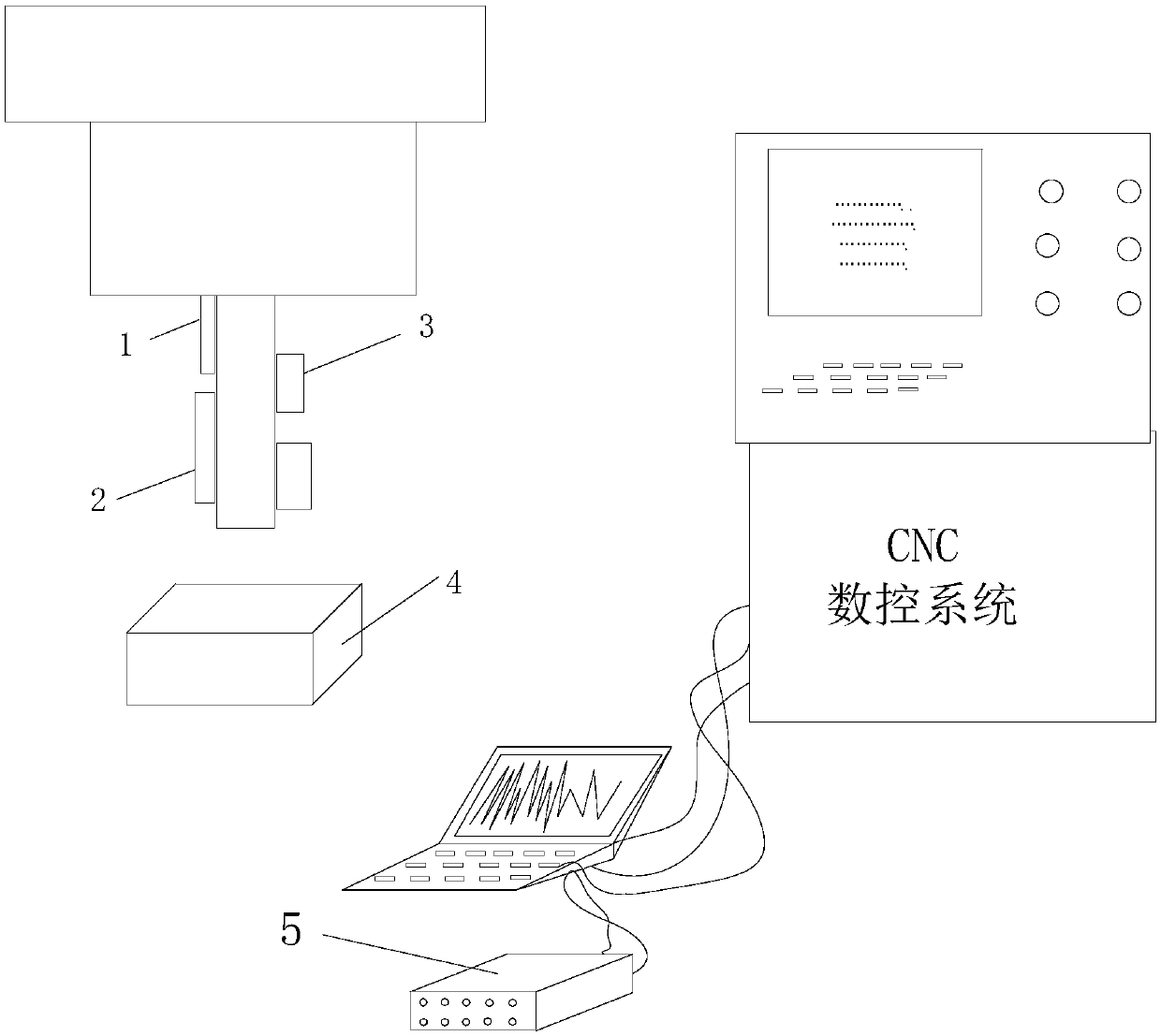

[0045] S1. Install displacement sensors, force sensors and acceleration sensors on the machine tool spindle and tool body to collect machine tool dynamic parameters;

[0046] S2. Transmitting the collected data to the database by wireless;

[0047] S3. Use the self-decision expert system based on BP neural network to learn, fuse and update the collected data;

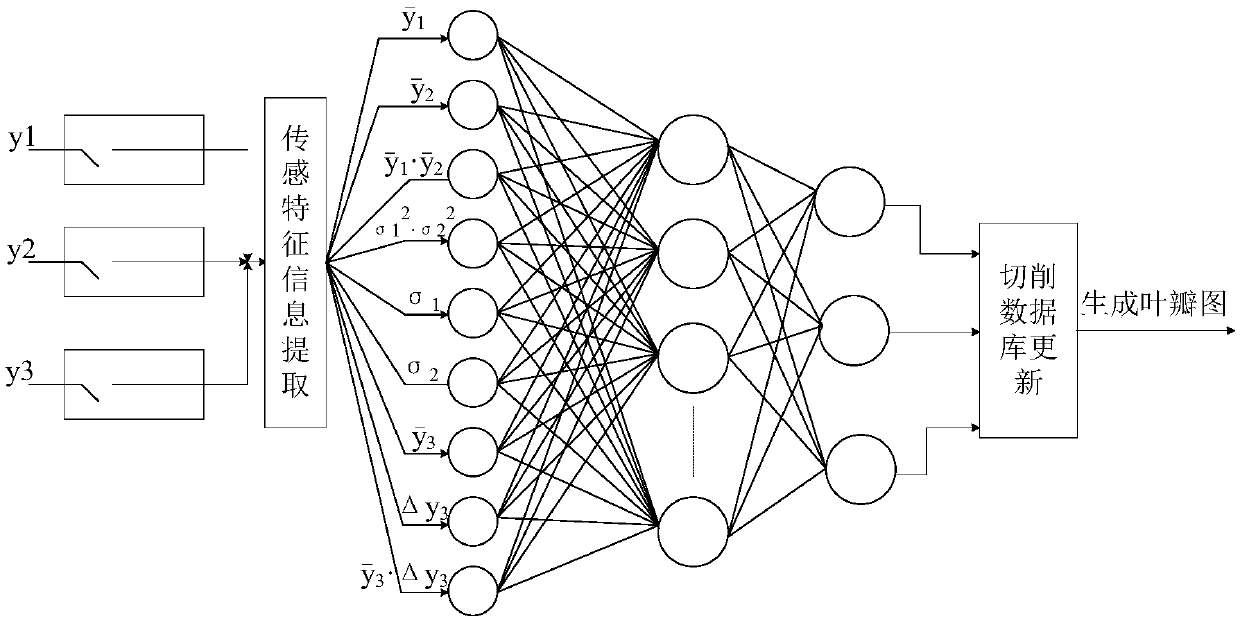

[0048] S4. Extract the characteristic information of the collected data, output the dynamic natural frequency, modal parameters and cutting force coefficient, and generate the stability lobe diagram of the real-time milling process;

[0049] S5. Find the NC code to obtain the processing parameters and bring them into the stability lobe diagram to determine whether the NC code needs to be optimized in the stability domain. If optimization is required, choose one or ex...

example

[0096] The method of the invention has been well verified in actual processing, and better results have been obtained. Table 1 is the comparison of parameters before and after static offline optimization of NC code.

[0097] Table 1

[0098]

[0099] Figure 7 It is to utilize the method of the present invention to obtain the comparison diagram of the effects before and after the optimization of the stability lobe diagram, wherein point A is in an unstable state before the NC code is dynamically optimized online, and point B is in a stable region after dynamic online optimization, and it can be seen that the improved Processing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com