Semiconductor structure and forming method therefor

A semiconductor and isolation structure technology, applied in the field of semiconductor structure and its formation, can solve problems such as adverse effects on the electrical performance of semiconductor devices, and achieve the effect of optimizing electrical performance, reducing oxidation, or avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background art that the formation process of the isolation structure in the prior art has a bad influence on the electrical performance of the semiconductor device. Analyze the reasons for this:

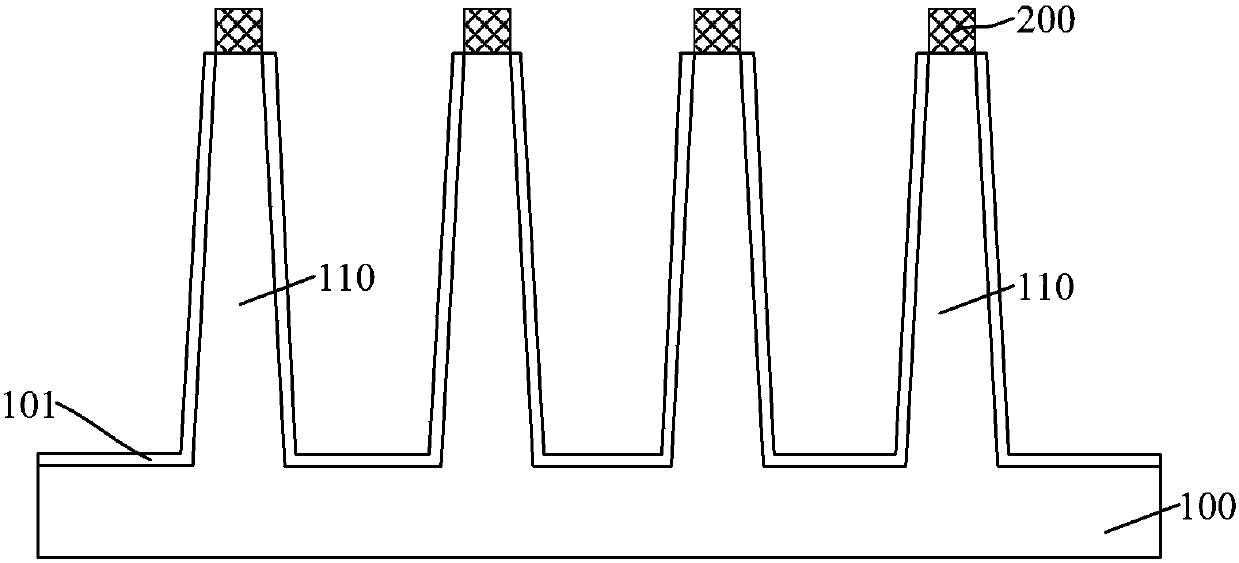

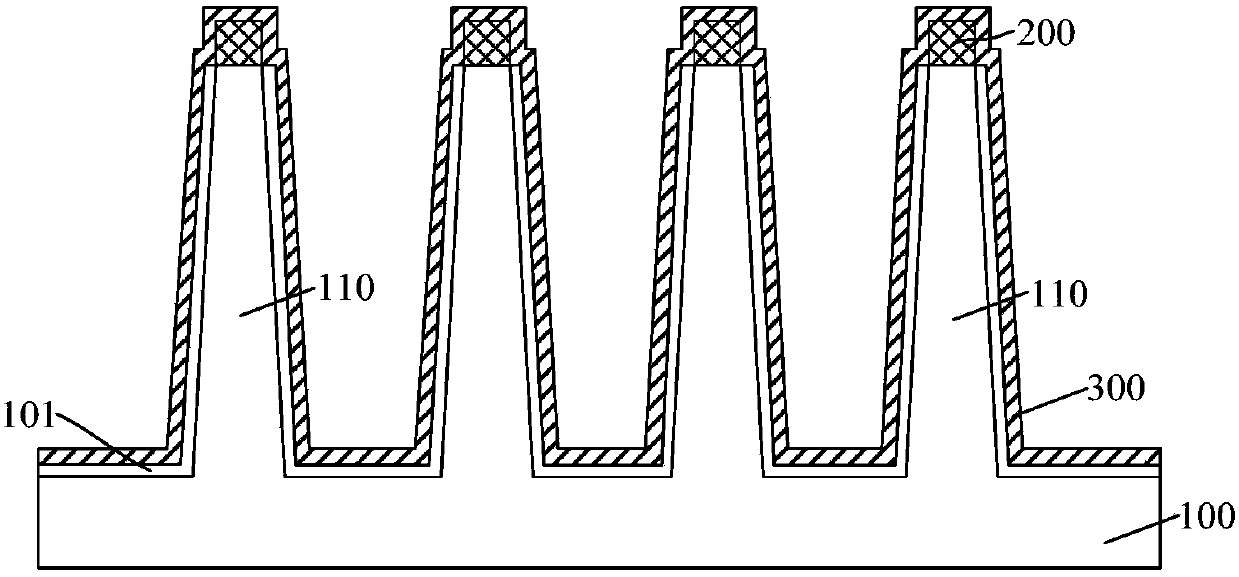

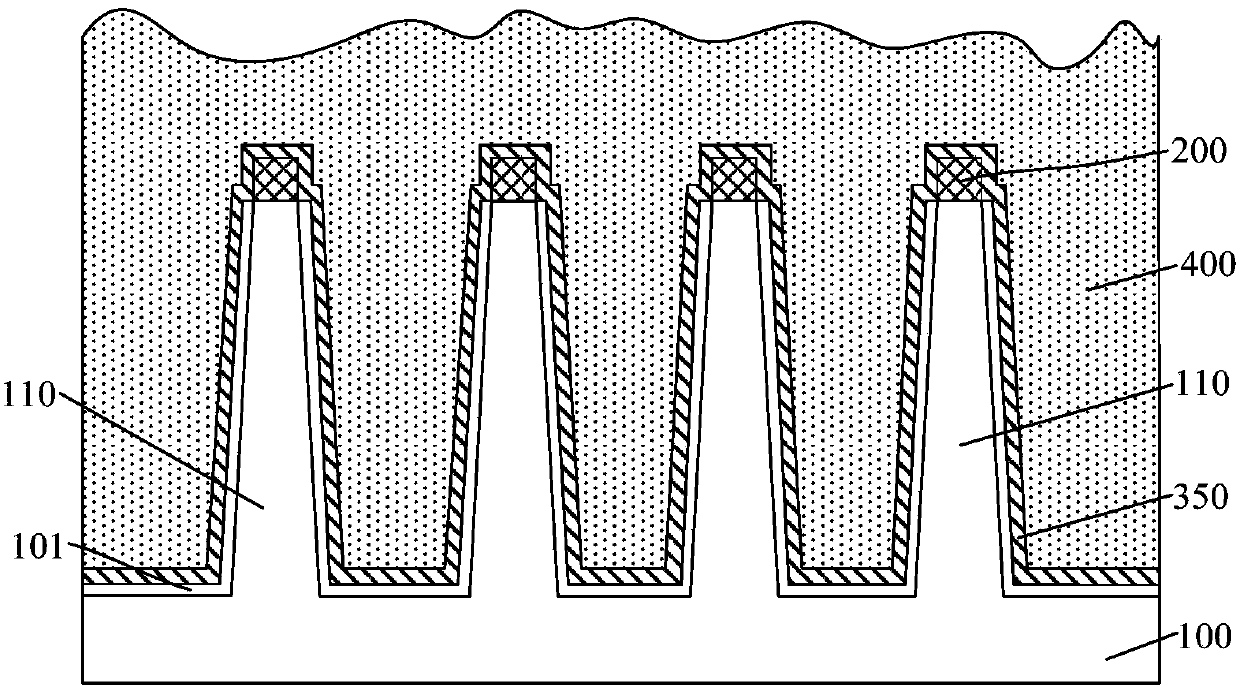

[0030] The process steps of forming the isolation structure mainly include: forming a substrate and fins protruding from the substrate; forming a precursor isolation film on the substrate between adjacent fins; performing an annealing process on the precursor isolation film , converting the precursor isolation film into an isolation film; removing part of the thickness of the isolation film to form an isolation structure.

[0031] However, the process of forming the precursor isolation film may easily oxidize the fin, thereby consuming part of the material of the fin, affecting the size of the fin, and easily leading to a decrease in the electrical performance of the semiconductor device.

[0032] In order to solve the technical problem, the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com