A sealing assembly process method for an eddy current brake stator assembly

An assembly process and stator technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of poor accuracy of test results, large influence of human factors, and inability to define weld seams, etc., achieve stable state, low price, and reduce air tightness experiments the effect of the link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

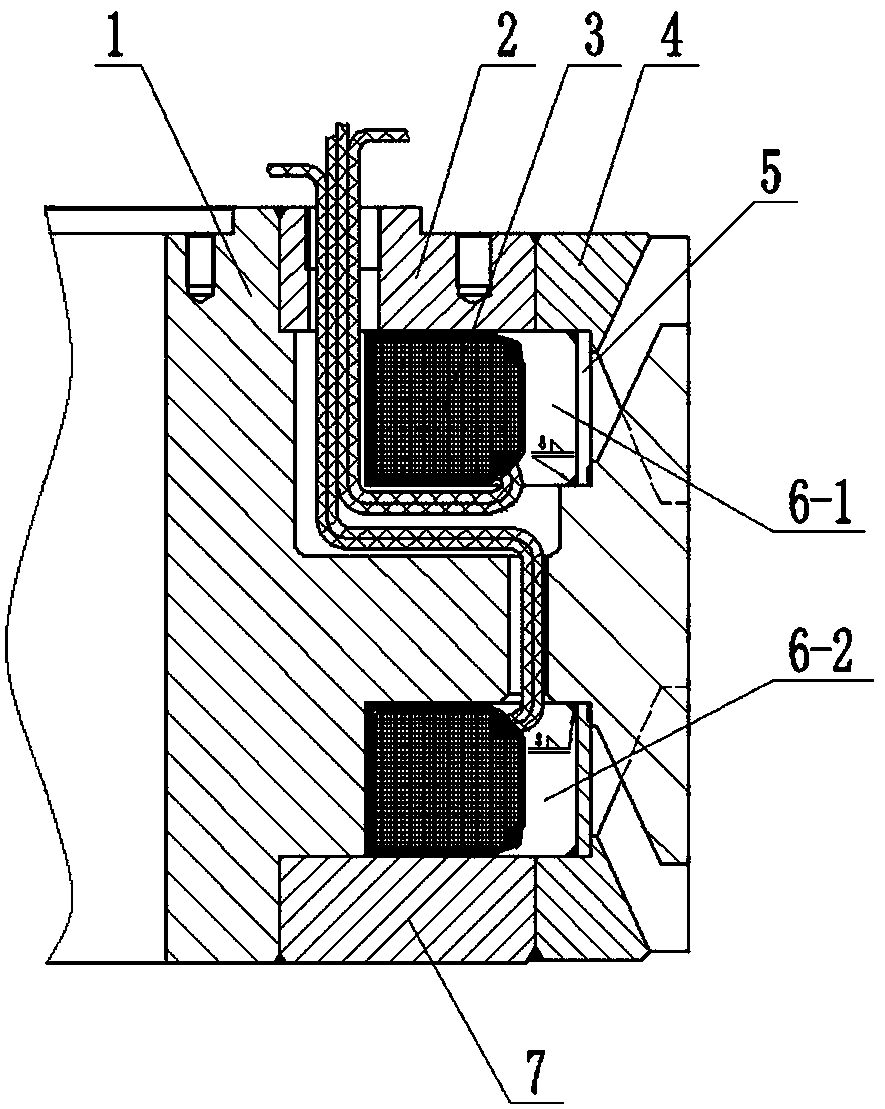

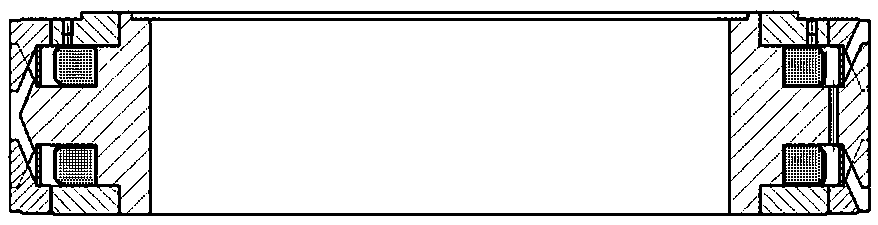

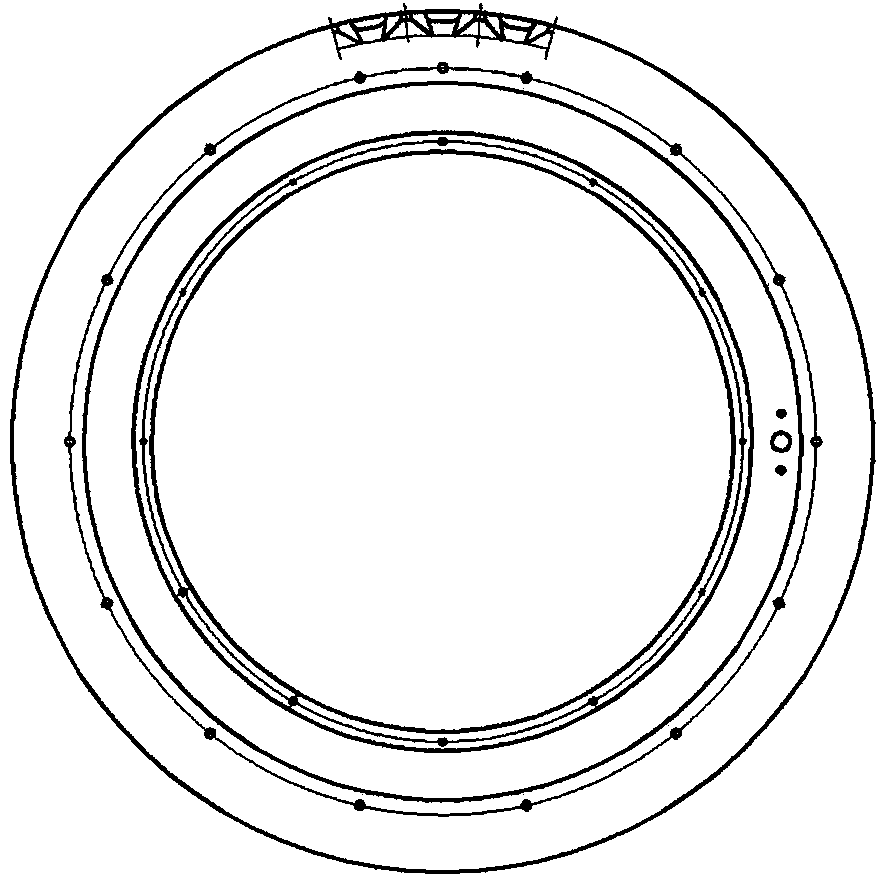

[0017] A sealing assembly process method for an eddy current brake stator assembly. The intermediate pole teeth 1, single pole teeth 4, and waterproof cover 5 of the stator assembly are assembled and welded, and the internal cavity of the coil 3 is cleaned and placed after welding, so that the internal cavity 6- 2 Facing upward, add insulating glue to the inner cavity 6-2 of the assembled stator assembly, and the insulating glue covers the bottom layer of the inner cavity 6-2, with a thickness of 4-5mm, and wait for the insulating glue to reach 70% of the complete solidification time Install the coil 3 at the same time, and then pour all the gaps vacated by the internal cavity 6-2 into the insulating glue, and wait for the insulating glue to completely solidify; put the right magnetic pole 7 into it for assembly welding, and rotate the stator assembly 180 degrees so that it is in the lower position The inner cavity 6-1 faces upwards, repeat the above operations, that is, add in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com