Glass rear cover and making method thereof

A technology on glass and glass, which is applied in the field of glass back cover and its preparation, can solve the problems of great harm to the human body and the environment, and achieve the effect of avoiding harm to the human body and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

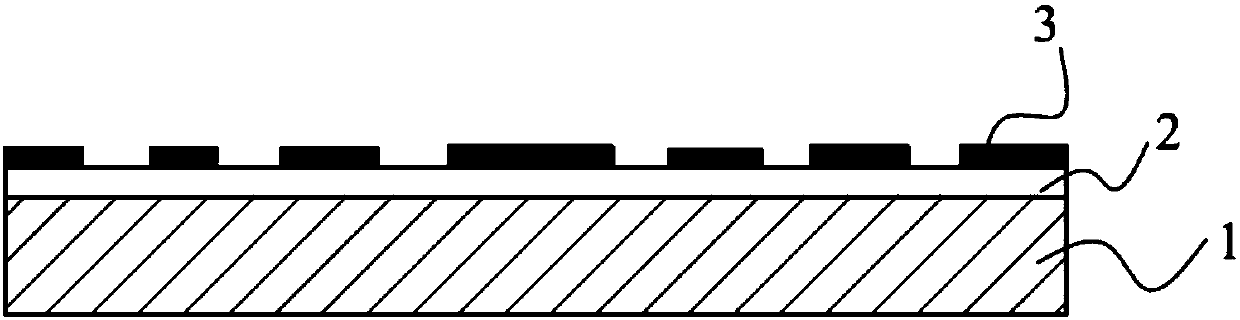

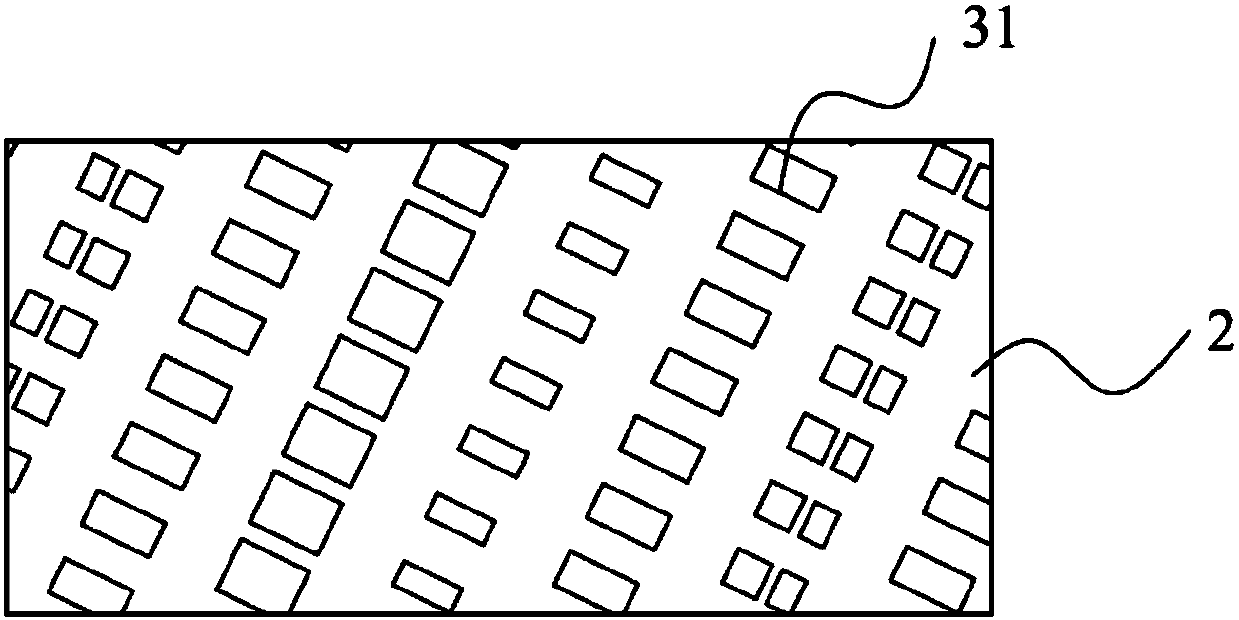

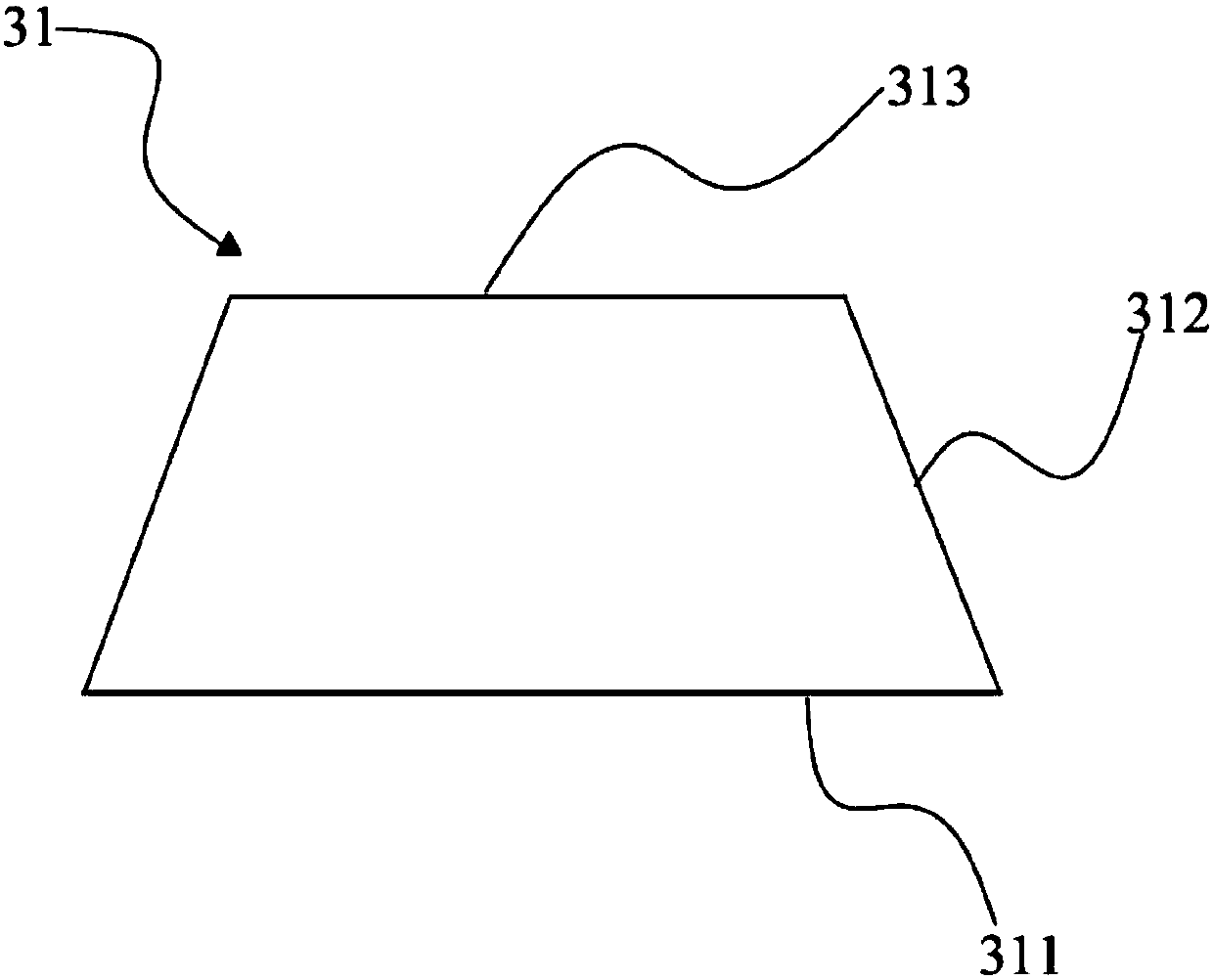

[0030] The first embodiment of the present invention provides a glass back cover, including a glass 1, a transparent base film 2 and a transparent photoresist pattern 3 formed on one side of the transparent base film 2, and the other side of the transparent base film 2 The side surface is bonded on the glass 1, and the transparent photoresist pattern 3 includes a plurality of monomer pattern blocks 31 arranged in an array on the transparent base film 2, and the plurality of monomer pattern blocks in the same row The center of 31 is on the first straight line, a plurality of single pattern blocks 31 in the same row are on the second straight line, the first straight line is perpendicular to the second straight line, and the single pattern blocks 31 are on the second straight line. The cutting dimensions on the first straight line and the second straight line are 20-50 μm, and the minimum distance between any two adjacent monomer pattern blocks 31 is 20-50 μm.

[0031] When the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com