Imitation manual processing method of Tongguan marinated meat in baked buns

A processing method, imitating manual technology, applied in dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling pin, baking, etc., can solve problems such as low efficiency and low production volume, and achieve reduction Labor intensity, increase output, and reduce the effect of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

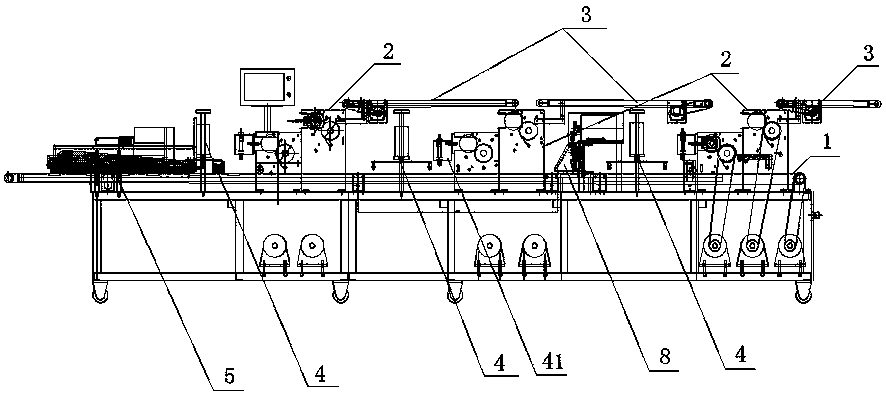

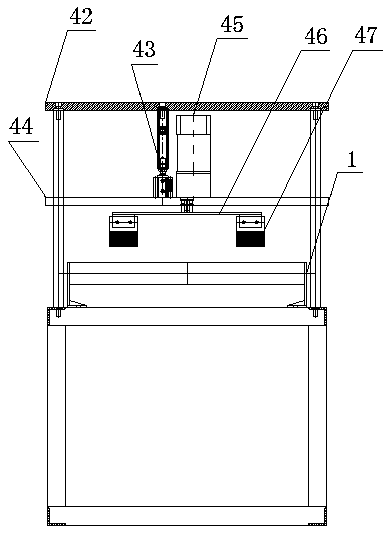

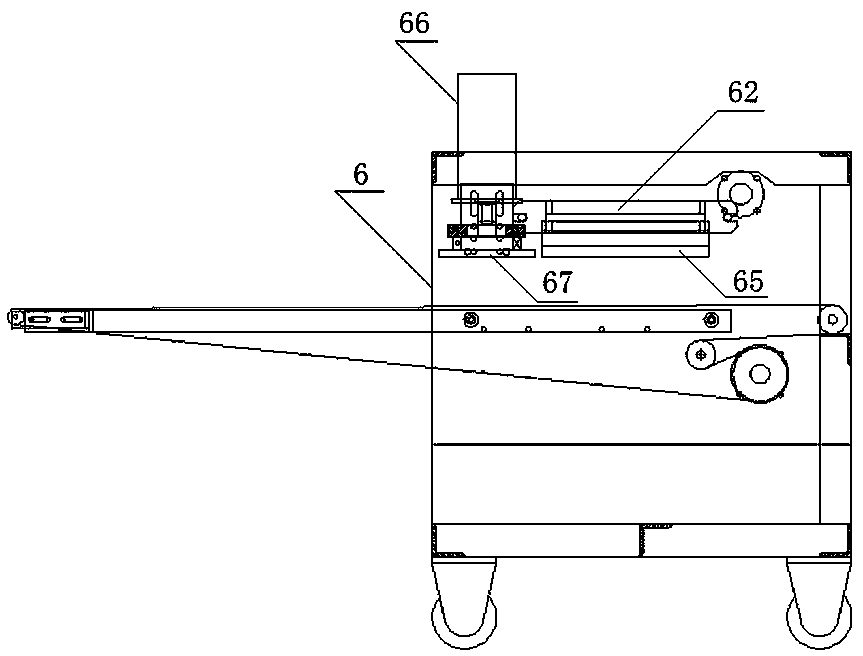

[0022] Such as Figure 1-6 As shown, a Tongguan Roujiamo imitates the manual processing method. The main conveyor belt 1 is used as the noodle transmission mechanism after the noodle is pressed. Several groups of noodle pressing mechanisms 2 are arranged on the main conveyor belt 1. In the noodle feeding mechanism 3, a group of oil brushing mechanism 4 is arranged behind the output ends of each group of noodle pressing mechanism 2, and the noodle belts output from several groups of noodle pressing mechanisms 2 are oiled and superimposed in multiple layers, and then the noodle rolling mechanism 5 passes through the noodle rolling mechanism 5. The layer belt is compacted, curled and formed, and sent to the kneading sub-mechanism 6, which gives the same dosage, and then the dosage is pre-pressed by the rotary pre-compression mechanism, and finally enters the rotary cake-rolling mechanism 7 to prepare buns. Embryo.

Embodiment 2

[0024] As a preference of embodiment 1, the noodle pressing mechanism 2 is provided with three groups, and a noodle transmission mechanism 3 with a certain length is arranged above each group of noodle pressing mechanism 2. The noodle pressing mechanism 2 includes two-stage noodle pressing rollers, which are independently The controlled motor provides power.

[0025] The noodle belt enters the first-stage noodle-pressing roller through the noodle-feeding mechanism 3 above the noodle-pressing mechanism 2, and enters the secondary noodle-pressing mechanism through the auxiliary conveyor belt. .

[0026] The oil brushing mechanism 4 is arranged behind each group of pressure-pressing mechanisms 2 in the face running direction, including an oil tank 41, a heating pipe arranged in the oil tank 41, an oil outlet arranged at the bottom of the oil tank 41, and a valve for controlling the oil outlet, And be arranged on the hairbrush device behind the oil tank, described hairbrush devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com