Quality guaranteeing method of frozen half shell mussels and application of quality guaranteeing method

A mussel quality technology, applied in the direction of freezing/cooling preservation of meat/fish, preservation of meat/fish with a protective coating, etc., can solve the problems of mussel products such as difficulty in exporting, protein denaturation, and quality deterioration, and achieve Excellent taste, long frozen storage period, and product quality assurance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

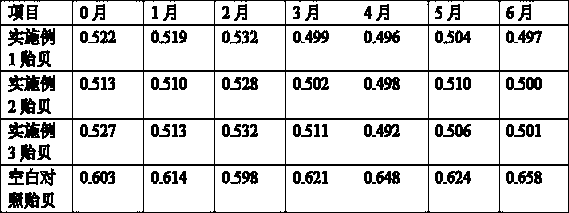

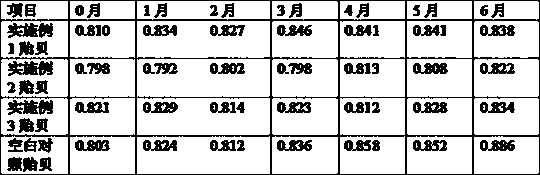

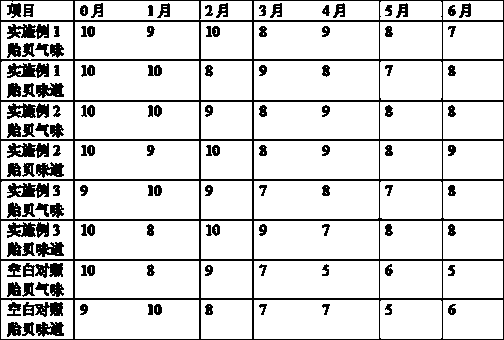

Examples

Embodiment 1

[0016] A quality assurance method for frozen half-shell mussels, the method steps are as follows: mussel pretreatment, antifreeze protection, film protection treatment, the specific steps are as follows:

[0017] 1) Mussel pretreatment: select mussels with an individual length of 7-9cm and wash them repeatedly with sea water for 3 times, and use ultraviolet light to sterilize them for 1.5min with a wavelength of 253.5, peel off one half shell of mussels and remove gills and feet Shredded and other sundries, ensure that the half-shell and meat pieces are connected together to get half-shell mussels;

[0018] 2) Antifreeze protection treatment: put half shell mussels in 16wt% antifreeze solution, immerse for 12 minutes with ultrasonic assistance, ultrasonic power is 120w, water temperature is 6°C, antifreeze consists of the following components and parts by weight: Mussel agglutinin 14 parts, chitooligosaccharide 50 parts, D-mannuronic acid heptasaccharide 0.32 parts, tea polyph...

Embodiment 2

[0023] A quality assurance method for frozen half-shell mussels, the method steps are as follows: mussel pretreatment, antifreeze protection, film protection treatment, the specific steps are as follows:

[0024] 1) Mussel pretreatment: select mussels with an individual length of 7-9cm, wash them twice with sea water in the cleaning tank, and use ultraviolet light for 1 minute to sterilize them. The wavelength of ultraviolet light is 253.7, and one half shell of the mussels is peeled off and the gills are removed. With the shredded silk and other sundries, ensure that the half-shell and the meat are connected together to get the half-shell mussel;

[0025] 2) Antifreeze protection treatment: put half shell mussels in 18wt% antifreeze solution, immerse them with ultrasonic assistance for 14min, the ultrasonic power is 100w, the water temperature is 5°C, and the antifreeze consists of the following components and parts by weight: 20 parts of mussel agglutinin, 60 parts of chitos...

Embodiment 3

[0031] A method for quality assurance of frozen half-shell mussels, the method steps are as follows: mussel pretreatment, antifreeze protection, film protection treatment, the specific preferred steps are as follows:

[0032] 1) Mussel pretreatment: select mussels with an individual length of 7-9cm and wash them twice with seawater in the cleaning tank, and then use ultraviolet light to sterilize them for 2 minutes, and the wavelength of ultraviolet light is 253.7, peel off one half shell of the mussels and remove the gills With the shredded silk and other sundries, ensure that the half-shell and the meat are connected together to get the half-shell mussel;

[0033] 2) Antifreeze protection treatment: put half shell mussels in 18wt% antifreeze solution, soak for 12 minutes with ultrasonic assistance, ultrasonic power is 150w, water temperature is 8°C, antifreeze consists of the following components and parts by weight: 15 parts of mussel agglutinin, 50 parts of chitosan oligos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com