Black tea and milk tea powder and preparation technology thereof

A preparation process and technology of milk tea powder, which is applied in the field of food processing, can solve problems such as easily destroying tea nutrients, affecting the taste and appearance of tea soup, and complicated milk tea preparation process, so as to avoid nutrient loss, have good uniformity, and improve fineness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

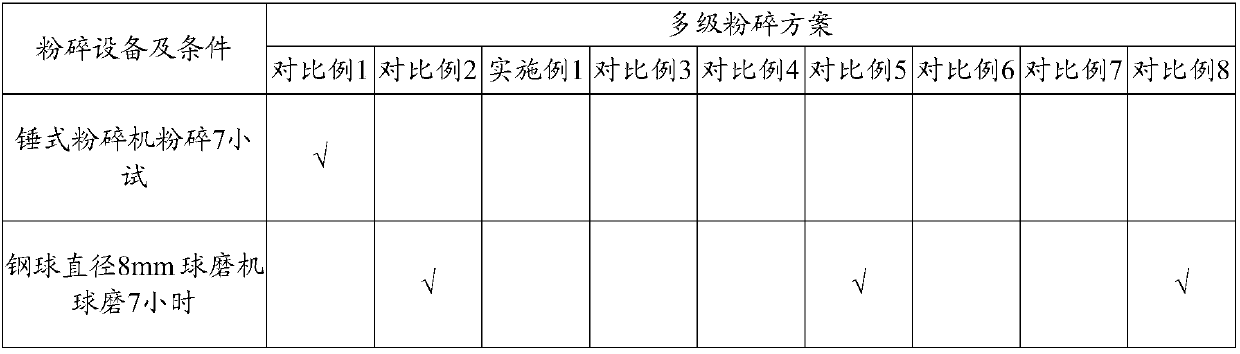

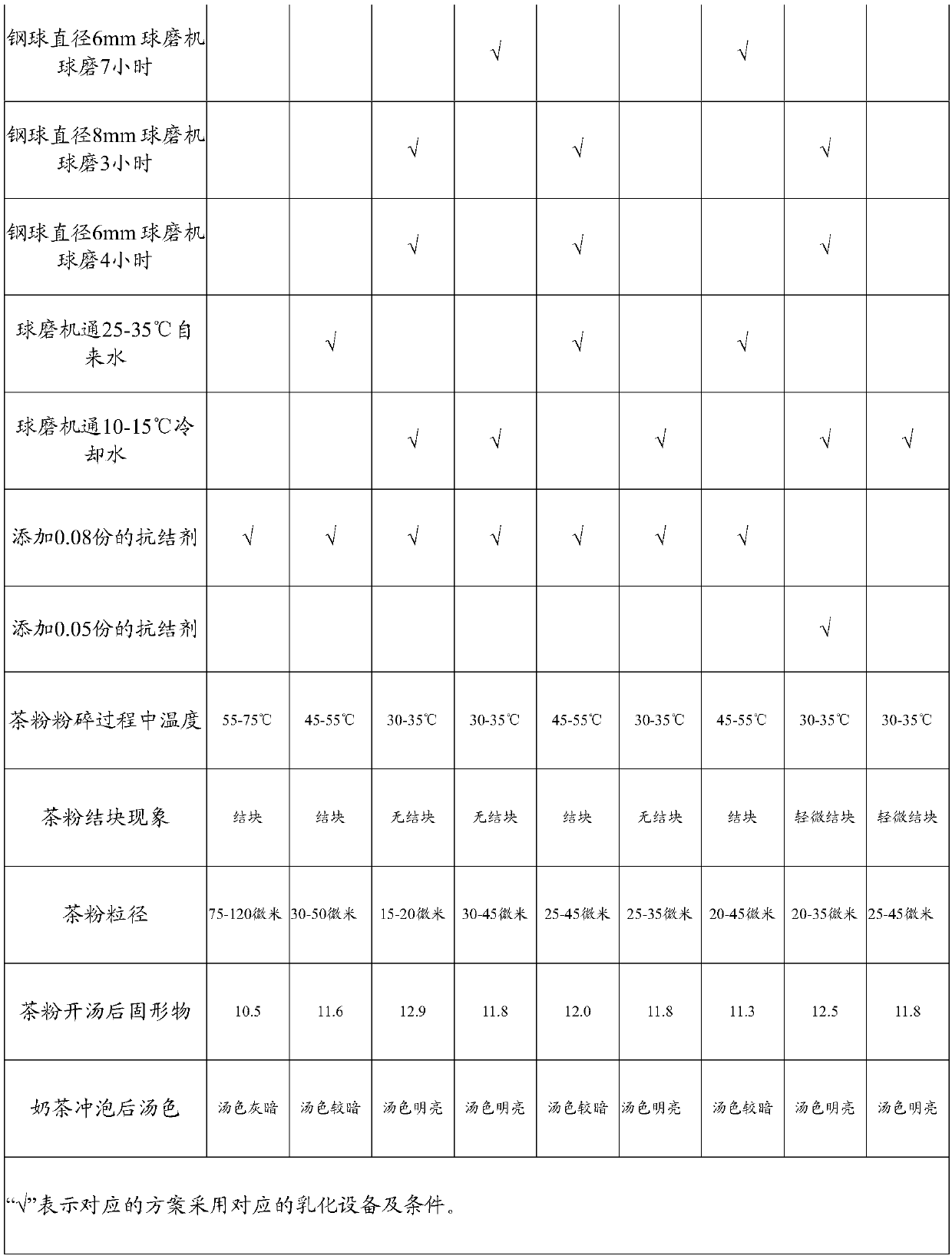

Examples

Embodiment 1

[0027] The present embodiment provides a kind of black tea milk tea powder, and it is calculated by weight, and described black tea milk tea powder consists of 15 parts of black tea powder, 18 parts of milk powder, 24 parts of white granulated sugar, 18 parts of maltodextrin, 12 parts of non-dairy creamer and 0.08 part of Anticaking agent composition, wherein the particle size of the black tea powder is 15 μm, and the black tea powder is made by pulverizing Assam black tea, the milk powder is whole milk powder, and the protein content in the whole milk powder is 30% , the non-dairy creamer is selected from the non-dairy creamer derived from hydrogenated vegetable oil, and its fat content is not less than 30%.

[0028] The present embodiment also provides a preparation process of the black tea milk tea powder, the process comprises the following steps:

[0029] S1. Put the Assam black tea and the anti-caking agent in the V-shaped mixing tank according to the above ratio, and mi...

Embodiment 2

[0037] The present embodiment provides a kind of black tea milk tea powder, and it is calculated by weight, and described black tea milk tea powder consists of 20 parts of black tea powder, 22 parts of milk powder, 32 parts of white granulated sugar, 23 parts of maltodextrin, 18 parts of non-dairy creamer and 0.12 parts of Anti-caking agent composition, wherein the particle size of the black tea powder is 20 μm, and the black tea powder is made by pulverizing Darjeeling black tea and Yunnan black tea, the milk powder is whole milk powder, and the protein content in the whole milk powder is 30%, the non-dairy creamer is selected from the non-dairy creamer derived from hydrogenated vegetable oil, and its fat content is not less than 30%.

[0038] The present embodiment also provides a preparation process of the black tea milk tea powder, the process comprises the following steps:

[0039] S1. Put Darjeeling black tea, Dianhong tea and anti-caking agent in a V-shaped mixing tank ...

Embodiment 3

[0047] The present embodiment provides a kind of black tea milk tea powder, and it is calculated by weight, and described black tea milk tea powder is made of 18 parts of black tea powder, 20 parts of milk powder, 26.9 parts of white granulated sugar, 20 parts of maltodextrin, 15 parts of non-dairy creamer and 0.1 part Anticaking agent composition, wherein the particle size of the black tea powder is 18 μm, and the black tea powder is made by pulverizing Assam black tea, the milk powder is whole milk powder, and the protein content in the whole milk powder is 30% , the non-dairy creamer is selected from the non-dairy creamer derived from hydrogenated vegetable oil, and its fat content is not less than 30%.

[0048] The present embodiment also provides a preparation process of the black tea milk tea powder, the process comprises the following steps:

[0049] S1. Put the Assam black tea and the anti-caking agent in the V-shaped mixing tank according to the above ratio, mix at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com