Laser welding method for medium plate and frame of mobile phone

A laser welding and frame technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of uneven solder joint size and poor welding strength, and achieve uniform solder joint size, high welding strength and deep penetration Consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a laser welding method for the middle panel and frame of a mobile phone. In order to make the purpose, technical solution and effect of the present invention clearer and more definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

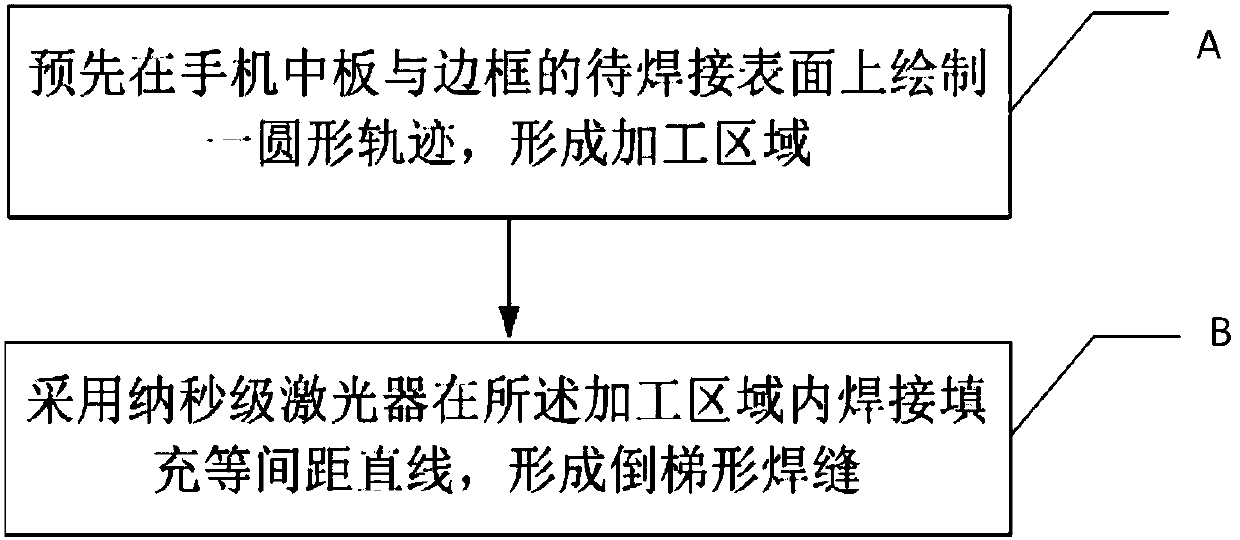

[0028] The invention provides a laser welding method for the middle plate and the frame of the mobile phone, such as figure 1 shown, including the following steps:

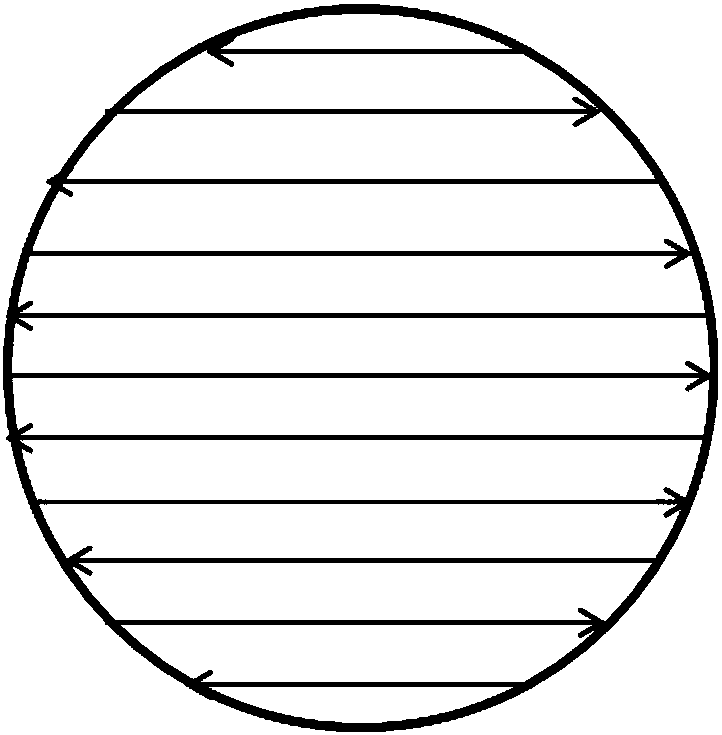

[0029] Step A, draw a circular track on the welding surface of the middle plate and frame of the mobile phone to form a processing area;

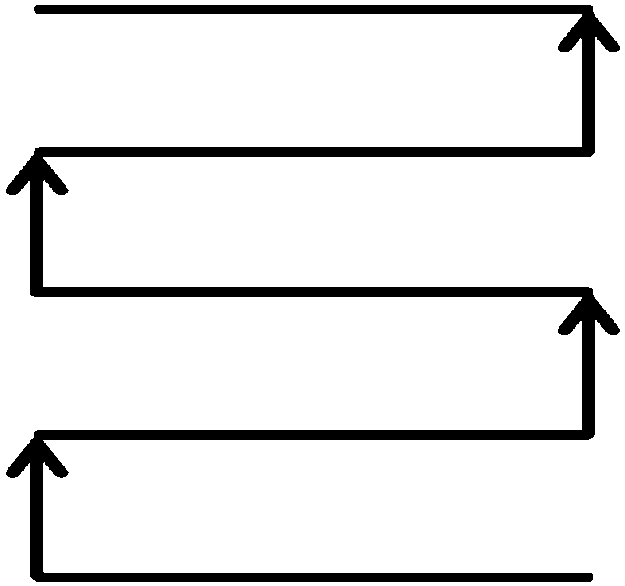

[0030] Step B. Using a nanosecond laser to weld and fill straight lines at equal intervals in the processing area to form an inverted trapezoidal weld.

[0031] Draw a circle on the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com