Color-sand sound absorption plate and preparation method thereof

A technology of sound-absorbing panels and colored sand, which is applied in the field of architectural sound-absorbing panels, can solve the problems of cumbersome process, complex structure, and lack of sound-absorbing performance, and achieve simple preparation process, low production cost, and good decorative visual effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

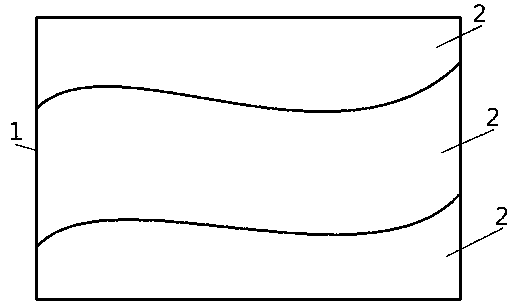

[0043] First, select three kinds of colored sand particles with a particle size of 0.25-0.425mm and colors of Phoenix Green, Grassland Green, and Hailan, and place them in their respective sealing devices according to different colors, and then start the vacuum cleaner connected to the top of the sealing device. Close after removing the mud and dust in the colored sand particles; then fully mix the above three colored colored sand particles with two-component epoxy resin with an amount of 8% of the colored sand particle mass and stir evenly, so that the three colors of colored sand particles The outer surface of the colored sand particles is covered with a layer of two-component epoxy resin with uniform thickness, and the curing agent is added at the same time or subsequently; at the same time, two pieces are placed at the specified positions in the 8mm thick colored sand sound-absorbing panel forming mold. The shape of the arc-shaped partition divides the forming mold into thr...

Embodiment 2

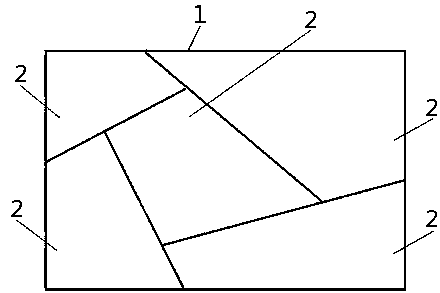

[0045] First, select five kinds of colored sand particles with a particle size of 0.425-0.85mm and colors of silver gray, gray jade, sapphire, white marble and evergreen, and place them in their respective sealing devices according to different colors, and then start the sealing device connected to the top. Vacuum cleaner, remove the mud and dust in the colored sand particles and turn off; then fully mix the colored sand particles with the color of silver gray and gray jade with the two-component epoxy resin with an amount of 10% of the mass of the colored sand particles and stir evenly, at the same time Fully mix the colored sand particles of sapphire, white marble and evergreen with the two-component epoxy resin with an amount of 15% of the mass of the colored sand particles and stir evenly, so that the outer surfaces of the colored sand particles of the five colors are covered with a layer of thickness Uniform two-component epoxy resin, add curing agent at the same time or l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com