A kind of stretch color-changing polyurethane elastomer material and preparation method thereof

A polyurethane elastomer and prepolymer technology, which is applied in the field of mechanochemical conductive materials, can solve the problem of lack of optional materials for mechanically responsive color-changing molecules and mechanically responsive discoloration, and achieve the effects of simple and controllable preparation method and sensitive mechanical force response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a preparation method of a stretchable color-changing polyurethane elastomer material, which is prepared from raw materials comprising the following components: oligomer diol, diisocyanate and hexaarylbiimidazole molecules, the hexaaryl Biimidazole molecules are a series of molecular switches with hydroxyl functional groups modified and designed with hexaarylbiimidazole as the main body of the molecule. Hexaarylbiimidazole has the structure shown in the following formula (2):

[0046]

[0047] As a preferred scheme wherein, the hexaarylbiimidazole molecules can have a structure as shown in any one of formula (three) to formula (eight):

[0048]

[0049] R in formula (three) to formula (eight) contains an alkyl group with 1 or 2 hydroxyl groups, preferably -(CH 2 ) 2 OH or -CH 2 CHOHCH 2 Oh. It should be pointed out that there are many kinds of R with a single and two hydroxyl groups, and only two of the most representative ones are listed...

Embodiment 1

[0065] Using PTMG as oligomer diol, MDI and HDI as diisocyanate, and 2,2'-diethanol alkoxyhexaarylbiimidazole molecules as raw materials to synthesize hexaarylbiimidazole block polyurethane elastomer stretching and discoloration Material. The molecular structure of 2,2'-diethanol alkoxyhexaarylbiimidazole is as follows.

[0066]

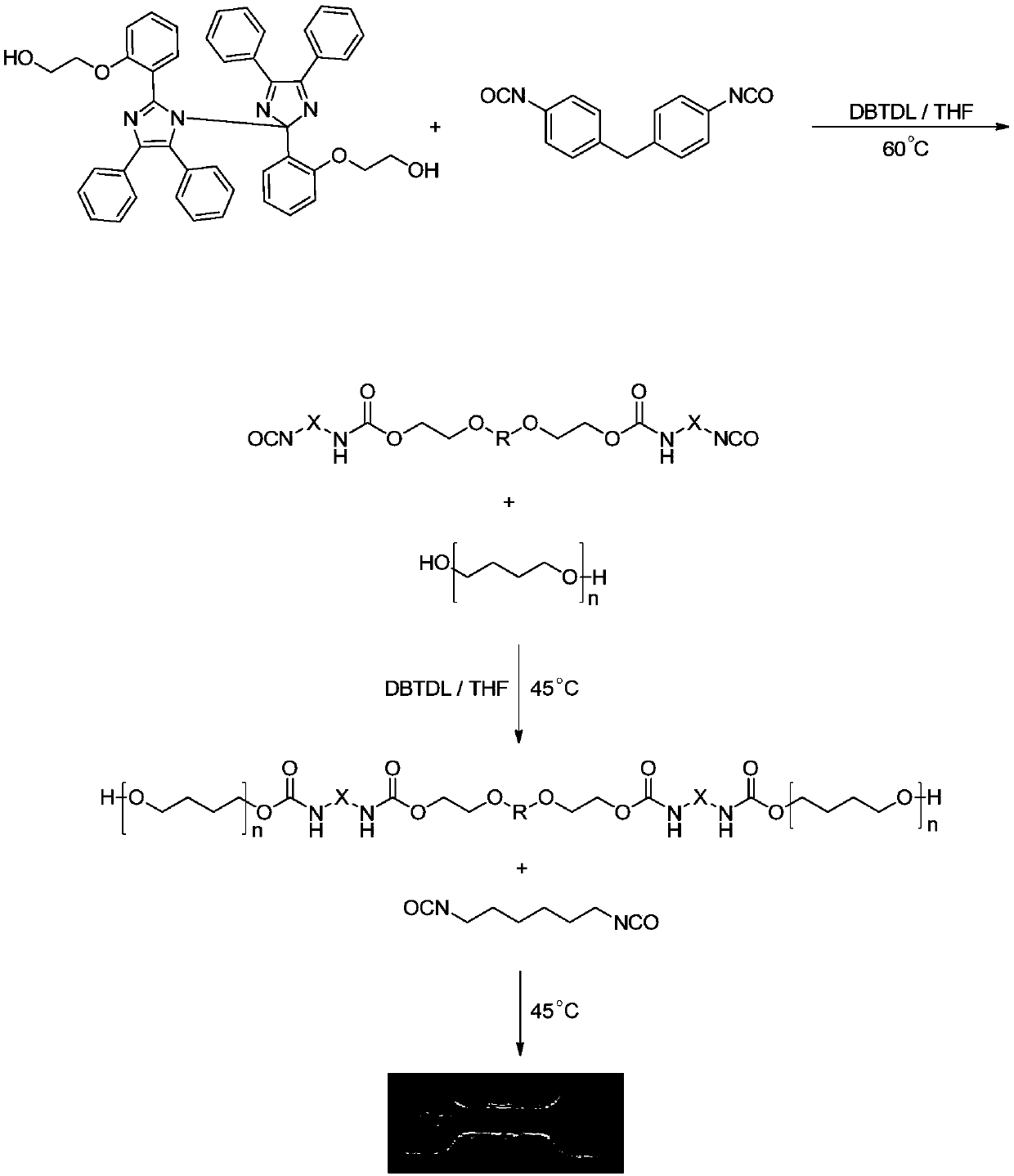

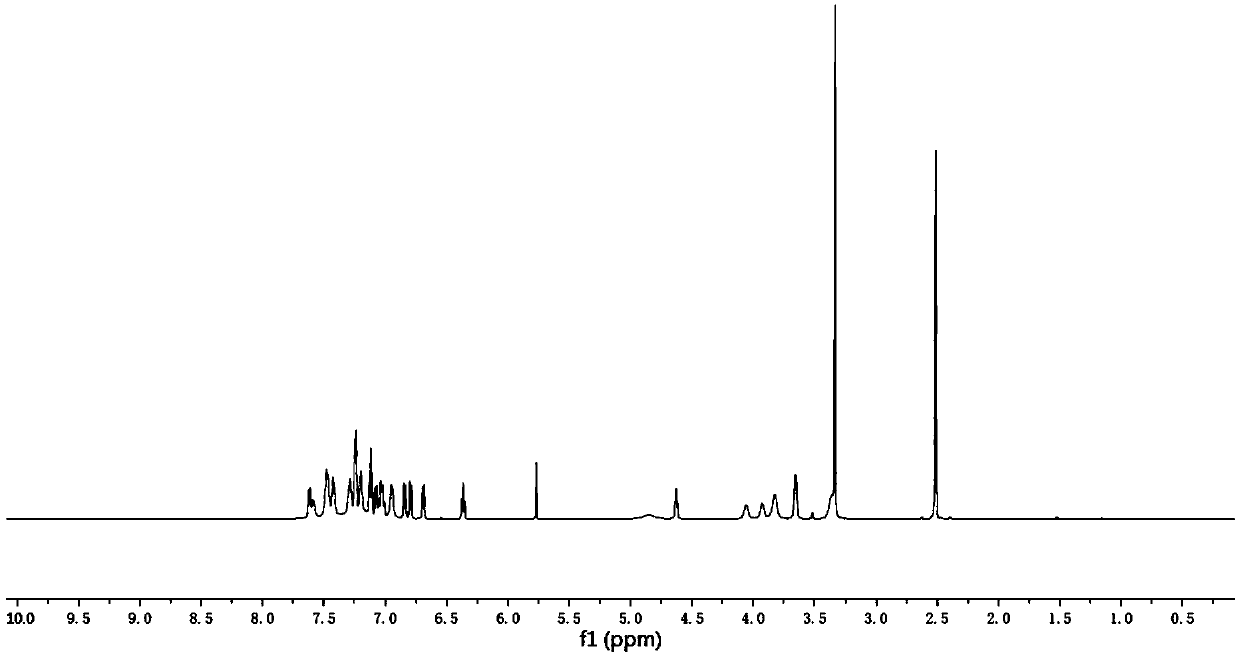

[0067] figure 1 It is a synthetic route diagram of the polyurethane elastomer stretching color-changing material synthesized from hexaaryl biimidazole blocks by using 2,2'-diethanol alkoxy hexaaryl biimidazole molecules as raw materials in Example 1. figure 2 It is the NMR spectrum of the 2,2'-diethanol alkoxyhexaarylbiimidazole molecule in Example 1. The 2,2'-diethanol alkoxyhexaarylbiimidazole molecule is synthesized through a three-step reaction. The first step is to react salicylaldehyde with dibromoethanol to obtain 2-diethanol alkoxybenzaldehyde; In the second step, 2-diethanolalkoxybenzaldehyde reacts with benzil to generate 2-diethanol...

Embodiment 2

[0073] Using PTMG as oligomer diol, MDI and HDI as diisocyanate, and 4,4'-diethanol alkoxyhexaarylbiimidazole molecules as raw materials to synthesize hexaarylbiimidazole block polyurethane elastomer Extensochromic material. The molecular structure of 4,4'-diethanol alkoxyhexaarylbiimidazole is as follows.

[0074]

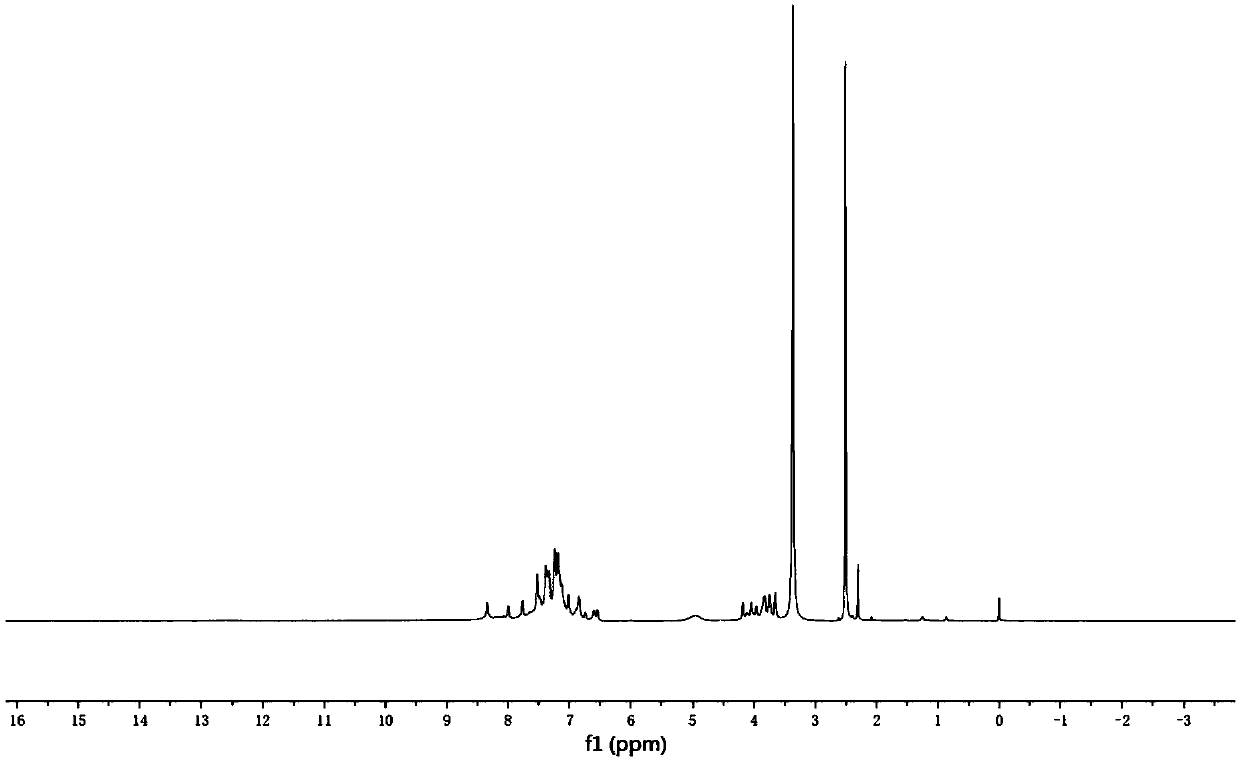

[0075] image 3 It is the NMR spectrum of the 4,4'-diethanol alkoxyhexaarylbiimidazole molecule in Example 2. The 4,4'-diethanol alkoxyhexaarylbiimidazole molecule is synthesized through a three-step reaction. The first step is to react p-hydroxybenzaldehyde with dibromoethanol to obtain 4-diethanol alkoxybenzaldehyde; In the second step, 4-diethanolalkoxybenzaldehyde reacts with benzil to generate 4-diethanolalkoxytriphenylimidazole; in the third step, oxidizes 4-diethanolalkoxytriphenylimidazole to generate 4,4'-diethanolalkoxyhexaarylbiimidazole molecule.

[0076]Weigh 4,4'-diethanol alkoxyhexaarylbiimidazole molecule (9mg, 0.0125mmol), put it into a rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com