A kind of semi-matte material for bopp semi-matte transfer base film and its preparation method and application

A semi-dull, base film technology, applied in the field of semi-dull materials and their preparation, can solve the problems of unstable matting effect, incomplete transfer, and insufficient uniformity, and achieve good transfer effect, uniform surface roughness, and distribution of morphology uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

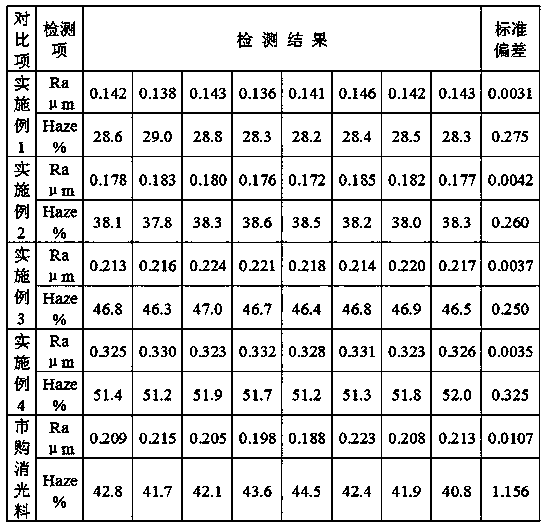

Embodiment 1

[0027] Binary copolymerized polypropylene——Borouge Plastics (Shanghai) Co., Ltd. RD239CF (8.0±2g / 10min): 86.8 parts;

[0028] High-density polyethylene——Sinopec Qilu Petrochemical Company DGDA6098 (0.11g / 10min, 0.948g / cm3): 8 parts;

[0029] Compatibilizer - Dow Chemical 2045G (1.0g / 10min, 0.920g / cm3): 5 parts;

[0030] Antioxidant (mixture of 1010 and 168, the mass ratio of the two is 1:2): 0.2 parts;

[0031] After fully mixing the raw materials of the above formula with a high-speed mixer, the twin-screw extruder melts and extrudes the strips, and the strips are pelletized and dried to make granulated finished products, and the BOPP semi-dull material is obtained.

Embodiment 2

[0033] Binary copolymerized polypropylene——Shanghai Petrochemical Co., Ltd. F800EDF (8.0±2g / 10min): 78.8 parts;

[0034] High-density polyethylene——Sinopec Qilu Petrochemical Company DGDA6098 (0.11g / 10min, 0.948g / cm3): 12 parts;

[0035] Compatibilizer - Mitsui Chemicals SP1520H (2.0g / 10min, 0.913g / cm3): 9 parts;

[0036] Antioxidant (mixture of 1010 and 168, the mass ratio of the two is 1:2): 0.2 parts;

[0037] After fully mixing the raw materials of the above formula with a high-speed mixer, the twin-screw extruder melts and extrudes the strips, and the strips are pelletized and dried to make granulated finished products, and the BOPP semi-dull material is obtained.

Embodiment 3

[0039] Binary copolymerized polypropylene——Borouge Plastics (Shanghai) Co., Ltd. RD239CF (8.0±2g / 10min: 72.8 parts;

[0040] High-density polyethylene——Exxon Mobil HTA-001HD5 (0.07g / 10min, 0.952g / cm3): 15 parts;

[0041] Compatibilizer——Shanghai Secco Petrochemical Co., Ltd. LL0220AA (2.4g / 10min, 0.921g / cm3): 12 parts;

[0042] Antioxidant (mixture of 1010 and 168, the mass ratio of the two is 1:2): 0.2 parts;

[0043] After fully mixing the raw materials of the above formula with a high-speed mixer, the twin-screw extruder melts and extrudes the strips, and the strips are pelletized and dried to make granulated finished products, and the BOPP semi-dull material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com