Method for producing large-specification Ti55531 alloy pancake

A ti55531, large-scale production technology, applied in the field of titanium alloy forging, can solve the problems of difficulty in obtaining uniform, high fracture toughness, large deformation resistance, etc., achieve good mechanical properties matching, reduce anisotropic difference, and ensure the effect of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

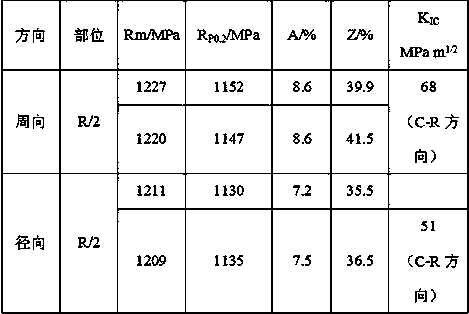

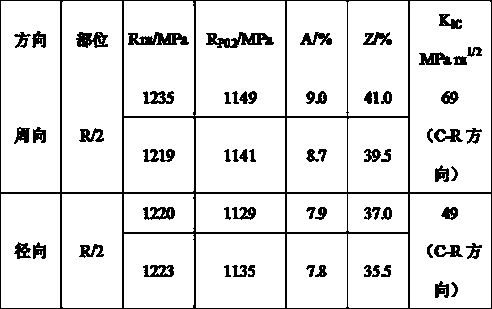

[0043] Example 2 (Φ1200mm*600mm cake base)

[0044] Step 1, blank forging:

[0045] Use an electric furnace to heat the Ti55531 ingot with a size of Φ650~780mm to 300°C above the β phase transition temperature, and keep it warm for 1500 minutes. After the end, use an 80MN fast forging machine to perform one fire, three upsetting and three drawing forgings. Upsetting at a uniform speed is required, and the upsetting rate is controlled at 10~20mm / s, the amount of upsetting deformation is controlled at 40~50%, so as to break the original cast structure;

[0046] Step 2, intermediate forging:

[0047] Step 2.1. The Ti55531 forging billet completed in step 1 is subjected to 4 times of double-upsetting and double-drawing forging at 300°C above the β-phase transition temperature, including 2 times of reversing upsetting and drawing, and single-fire times of upsetting and drawing deformation control At 40~45%, the upsetting rate is controlled at 10~20mm / s;

[0048] Step 2.2. The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com