Method for detecting dissimilar material pipeline sectional area loss based on ultrasonic guided-wave technology

A technology of ultrasonic guided wave and detection method, which is applied in the direction of material analysis, measuring device, and analysis material using sound wave/ultrasonic wave/infrasonic wave, which can solve the problems such as difficulty in ensuring detection accuracy and reliability, reducing detection efficiency, and loss of magnetic energy. Achieve the effect of improving the range and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

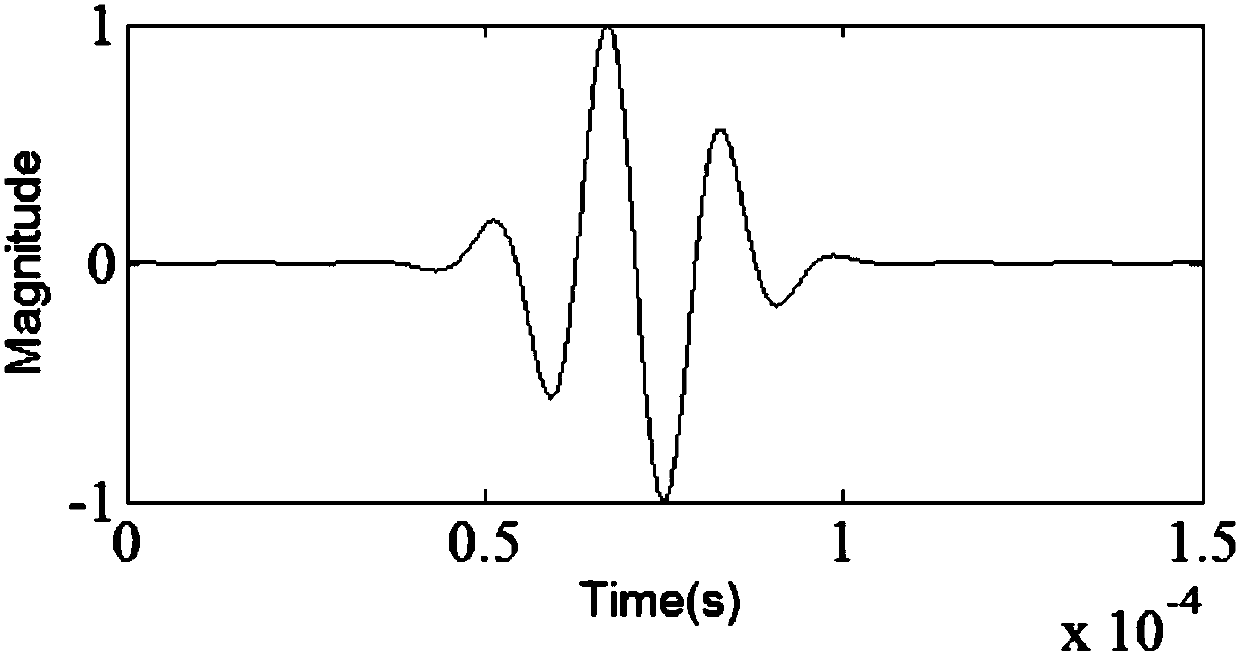

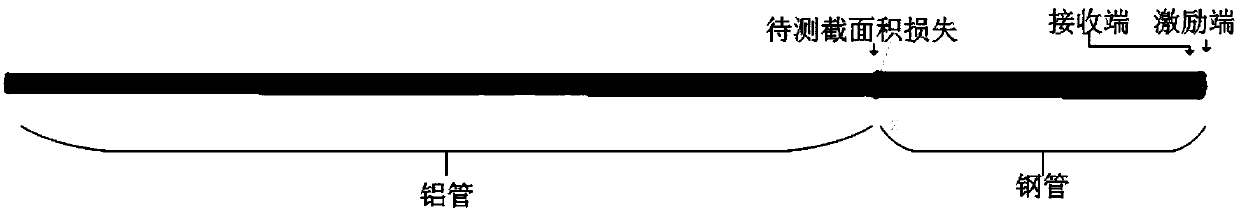

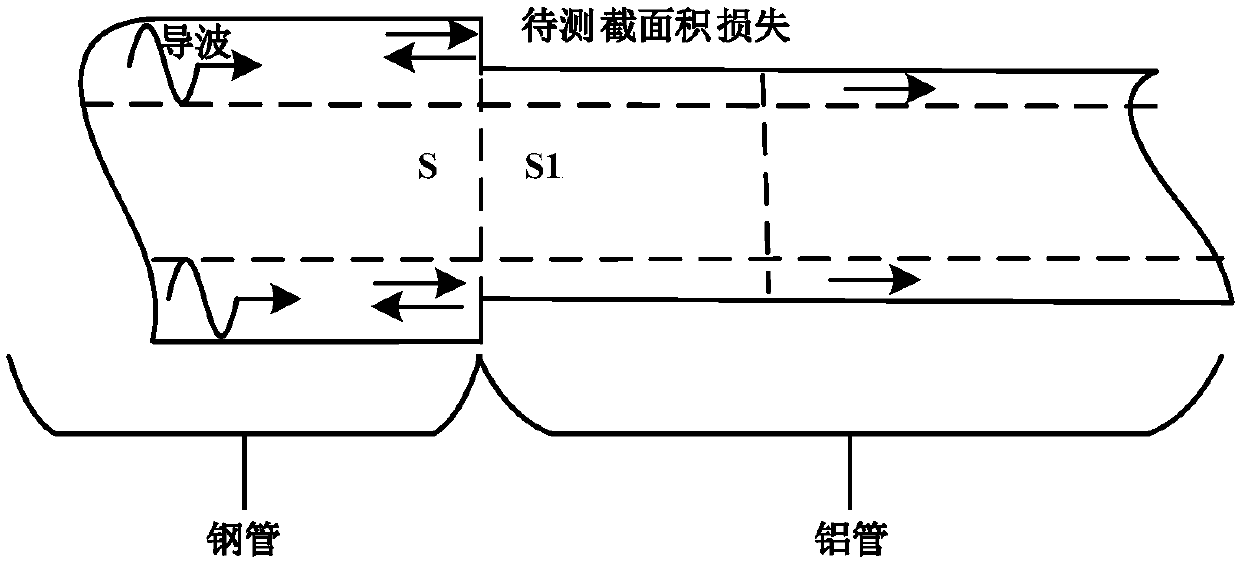

[0026] Such as figure 2 , 3 The principle diagram of pipeline detection of dissimilar materials and the schematic diagram of cross-sectional area loss are shown. In this embodiment, the specific two-material pipeline is taken as an example to expand the guided wave detection of cross-sectional area loss in the pipeline. The implementation process is as follows:

[0027] 1) Here, the cross-sectional area loss detection of guided wave technology is realized by simulating dissimilar material pipes. Using the three-dimensional simulation software ABAQUS, according to the parameters in Table 1 and Table 2, the physical model of the pipeline with different materials is established.

[0028] Table 1 pipeline parameters

[0029]

[0030] Table 1 shows the pipe parameters for steel pipes and Table 2 shows the parameters for aluminum pipes.

[0031] Table 2 pipeline parameters

[0032]

[0033] Steps such as setting components and material properties in ABAQUS, the two materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com