Preparation method of modified cadmium telluride thin film solar cell

A technology of solar thin film and solar energy, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high investment cost, inability to use, and narrow application range of greenhouses, etc., achieve good overall visual effects, increase service life, and improve visual effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The technical solution provided by the invention is a method for preparing an improved cadmium telluride solar thin-film battery, comprising the following steps:

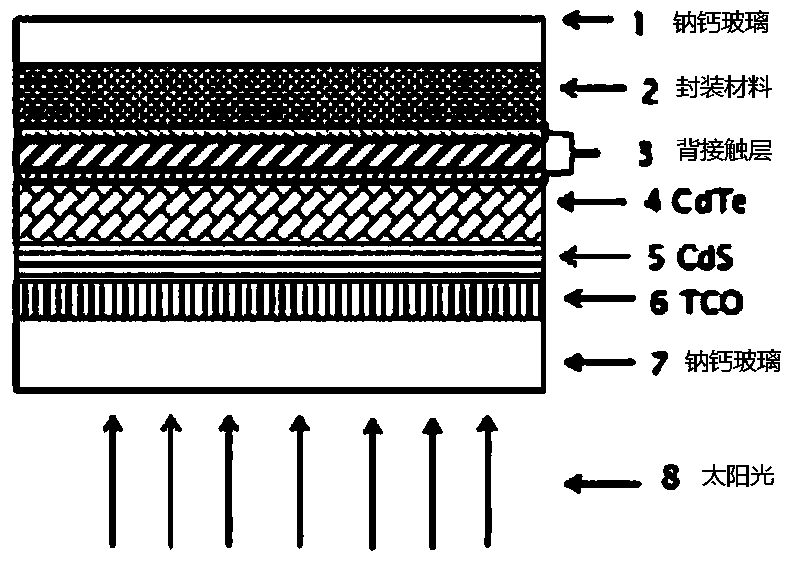

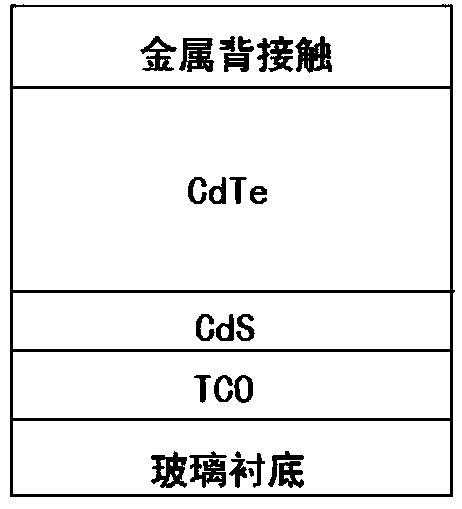

[0048] 1) A layer of N-type layer and a light-absorbing layer are sequentially covered on the upper surface of the conductive glass to obtain a solar electrode sheet; wherein, the conductive glass is obtained by covering a layer of TCO or FTO film on the upper surface of soda-lime glass;

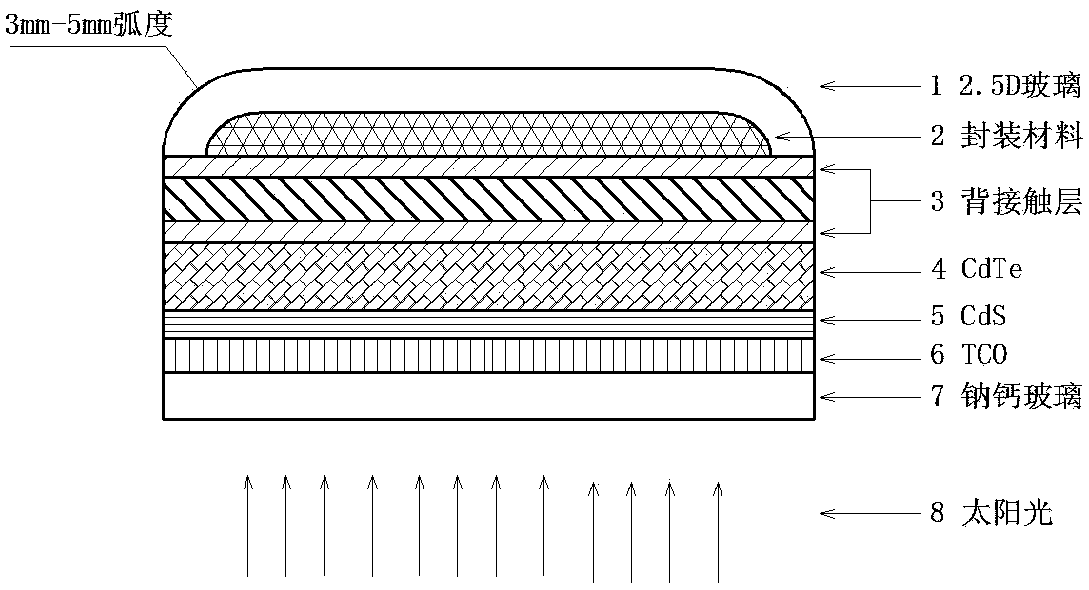

[0049] 2) Covering the upper surface of the solar electrode sheet prepared in step 1) with a back contact layer, bonding a back sheet on the back contact layer to obtain a prefabricated part, the back sheet is 2.5D tempered glass;

[0050] 3) Laminate the preform in an autoclave laminator for 2-4 hours under the conditions of 100-120° C. and 0.3-1.5 Mpa, and then remove the vacuum bag to obtain an improved cadmium telluride solar thin film battery.

Embodiment 1

[0053] A method for preparing an improved cadmium telluride solar thin film battery, comprising the following steps:

[0054] 1) Cover a layer of TCO film, CdS film and CdTe film on the upper surface of the soda-lime glass in order to obtain a solar electrode sheet, wherein the thicknesses of the TCO film, CdS film and CdTe film are 150nm, 45nm and 3000nm respectively

[0055] 2) Cover the upper surface of the solar electrode sheet prepared in step 1) with a layer of ZnTe:Cu, and combine 2.5D tempered glass with ZnTe:Cu by adding POE polymer to obtain a prefabricated part, wherein, 2.5D tempered glass The thickness of the glass is 3.2mm, after the edge is curved, the width of the arc is 3mm, the thickness of ZnTe:Cu is 350nm, and the thickness of the polymer POE is 0.4mm;

[0056] 3) Laminate the preform obtained in step 2) under the conditions of 100°C and 1 Mpa for 2 hours in an autoclave laminator, and remove the vacuum bag to obtain an improved cadmium telluride solar thin...

Embodiment 2

[0059] A method for preparing an improved cadmium telluride solar thin film battery, comprising the following steps:

[0060] 1) A layer of TCO film, CdS film and CdTe film is covered successively on the upper surface of soda lime glass to obtain a solar electrode sheet, wherein the thicknesses of the TCO film, CdS film and CdTe film are respectively 150nm, 45nm and 2500nm;

[0061] 2) Cover the upper surface of the solar electrode sheet prepared in step 1) with a layer of ZnTe:Cu, and combine 2.5D tempered glass with ZnTe:Cu by adding POE polymer to obtain a prefabricated part, wherein, 2.5D tempered glass The thickness of the glass is 2.0mm, after the edge is curved, the width of the arc is 5mm, the thickness of ZnTe:Cu is 350nm, and the thickness of the polymer POE is 0.4mm;

[0062] 3) Laminate the preform obtained in step 2) under the conditions of 100°C and 1 Mpa for 2 hours in an autoclave laminator, and remove the vacuum bag to obtain an improved cadmium telluride sola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com