Automatic loading device for solar cell module junction box and fixture matched with loading device

A solar cell and automatic feeding technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems that plague the development of full automation of solar cell module packaging, large differences in wire length, and irregular shape of junction boxes, etc., to achieve Effects of reducing component costs, stabilizing product quality, and eliminating quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

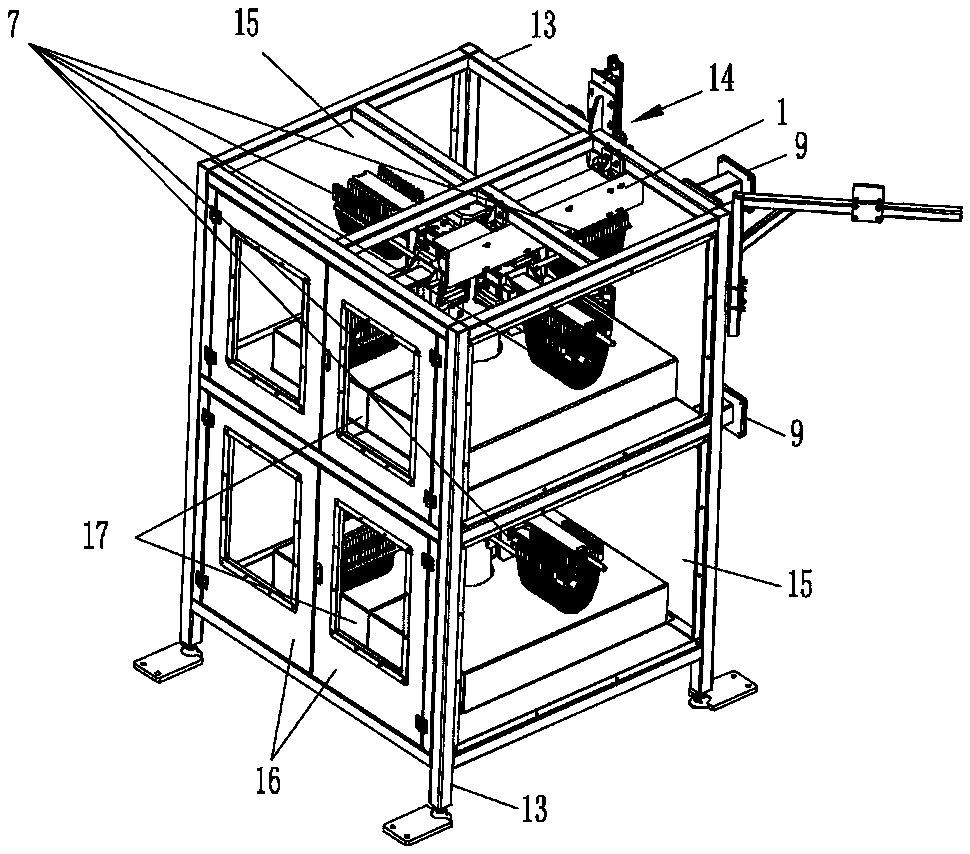

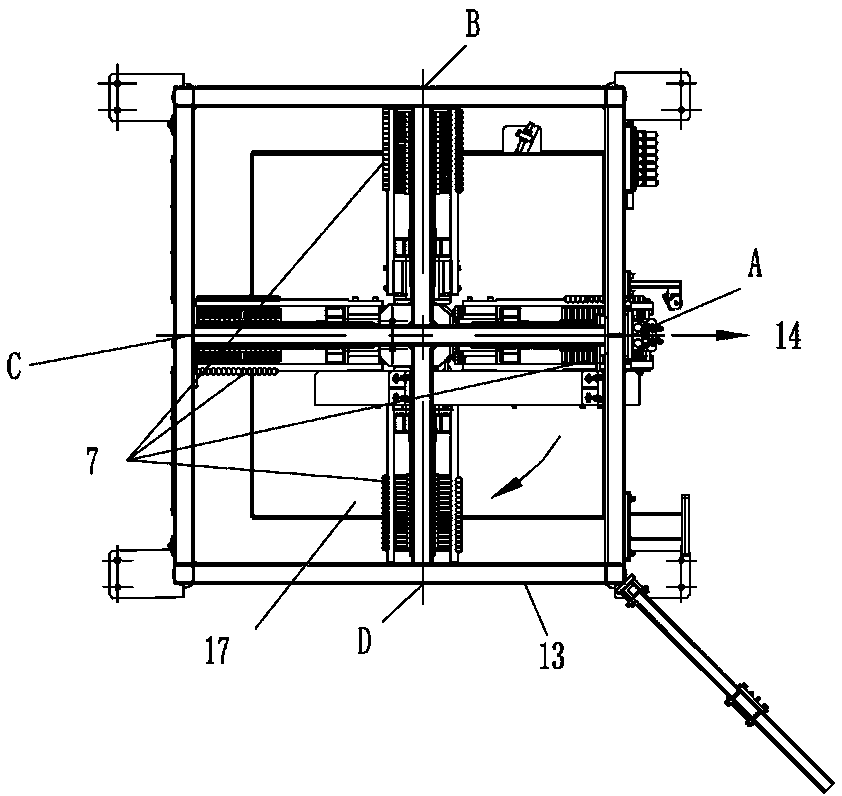

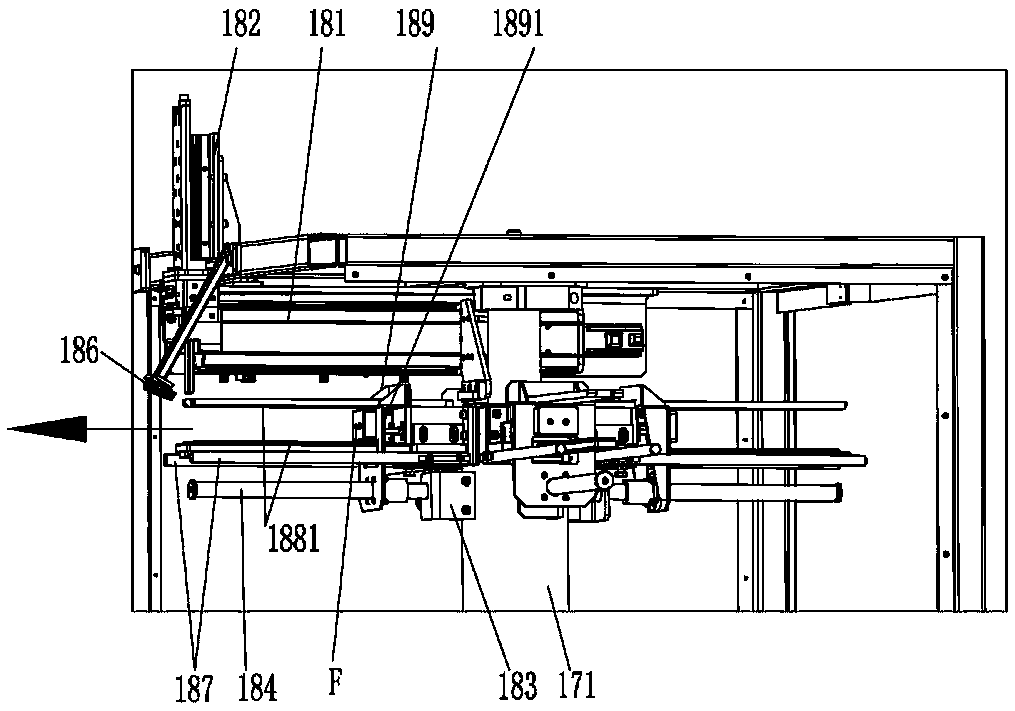

[0028] The solar battery module junction box automatic feeding device of the present invention includes a frame 13, and is characterized in that: a junction box silo 1 is arranged inside the frame 13, and the junction box silo 1 includes a support plate 1881 that cooperates with the junction box 7, The side of the support plate 1881 is provided with a wire limit column 187, and the bottom of the support plate 1881 is provided with an optical axis 184 that cooperates with the round wire 73. One end of the support plate 1881 and the optical axis 184 is provided with a pusher plate through the linear module 181 189 ; the frame 13 is provided with a material blocking device 182 opposite to the pushing plate 189 of the junction box magazine 1 .

[0029] As a preferred solution of the present invention, a rotating device 17 is arranged in the frame 13, and at least three junction box bins 1 are arranged on the rotating device 17; one side of the frame 13 is a discharge port 14; The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap