Magnetic refrigeration cooling device and control system

A heat dissipation device and control system technology, applied in refrigerators, refrigeration and liquefaction, cooling/ventilation/heating transformation, etc., can solve the problems that the heat dissipation threshold cannot be lower than room temperature, poor environmental adaptability, low heat dissipation efficiency, etc., and achieve heat transfer Fast, long service life, high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

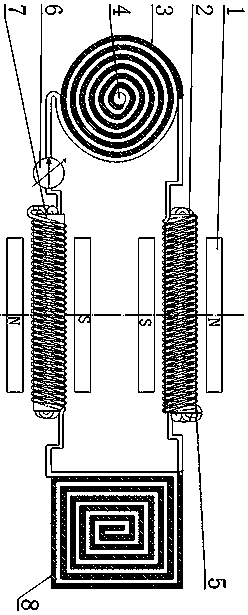

[0040] In this embodiment, a schematic diagram of the structure and principle of a magnetic cooling and heat dissipation device and a control system is as follows: figure 1 As shown, including magnetic refrigeration system, heat dissipation system and drive control system.

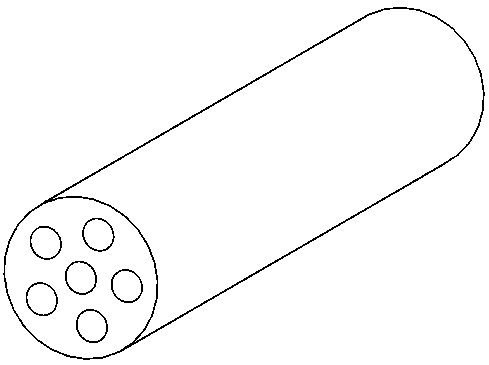

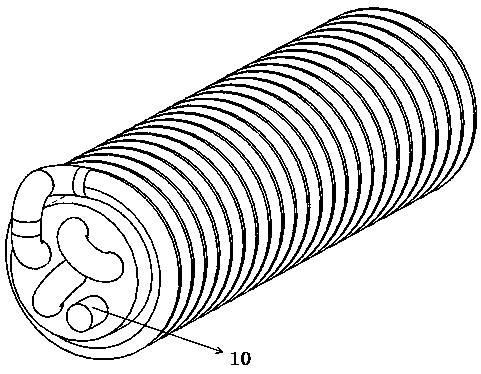

[0041] The magnetic refrigeration system includes a magnetic field system 1, a first magnetic working medium device 2, a second magnetic working medium device 7, a cooling end and a heating end; the magnetic field system is composed of two pairs of electromagnets, and the electromagnets are composed of The single-chip microcomputer in the drive control system drives and controls the electromagnet through the set program to periodically generate the magnetic field required by the magnetic refrigeration system. The magnetic working medium is placed in the magnetic field system 1, and its magnetic moment follows the magnetic field of the electromagnet. The change of the direction is neat or disorderly; the ma...

Embodiment 2

[0065] In this embodiment, a schematic diagram of the structure and principle of a magnetic cooling and heat dissipation device and a control system is as follows: Figure 9 As shown, including magnetic refrigeration system, heat dissipation system and drive control system.

[0066] The magnetic refrigeration system includes a magnetic field system 1', a first magnetic working medium device 2', a cooling end and a heating end; the magnetic field system 1' is composed of a pair of electromagnets, and the electromagnets are controlled by the drive control system The single-chip microcomputer drives and controls the electromagnet through the set program to periodically generate the magnetic field required by the magnetic refrigeration system. The magnetic working medium 2' is placed in the magnetic field system 1', and its magnetic moment follows the direction of the magnetic field of the electromagnet. The changes are either neat or messy.

[0067] The heat dissipation system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com