Electron beam irradiation device

一种电子射线、照射装置的技术,应用在电子射线照射装置领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

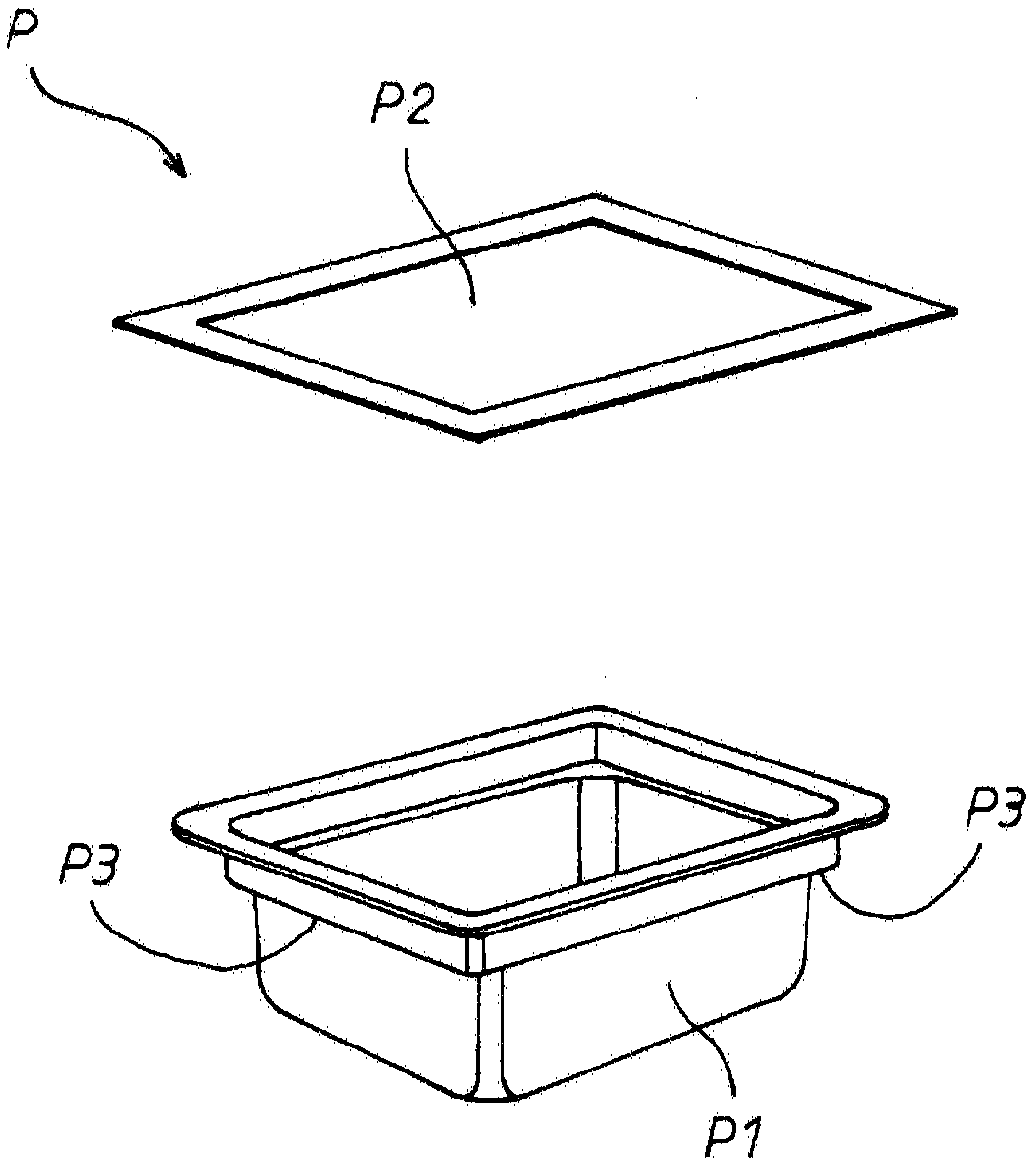

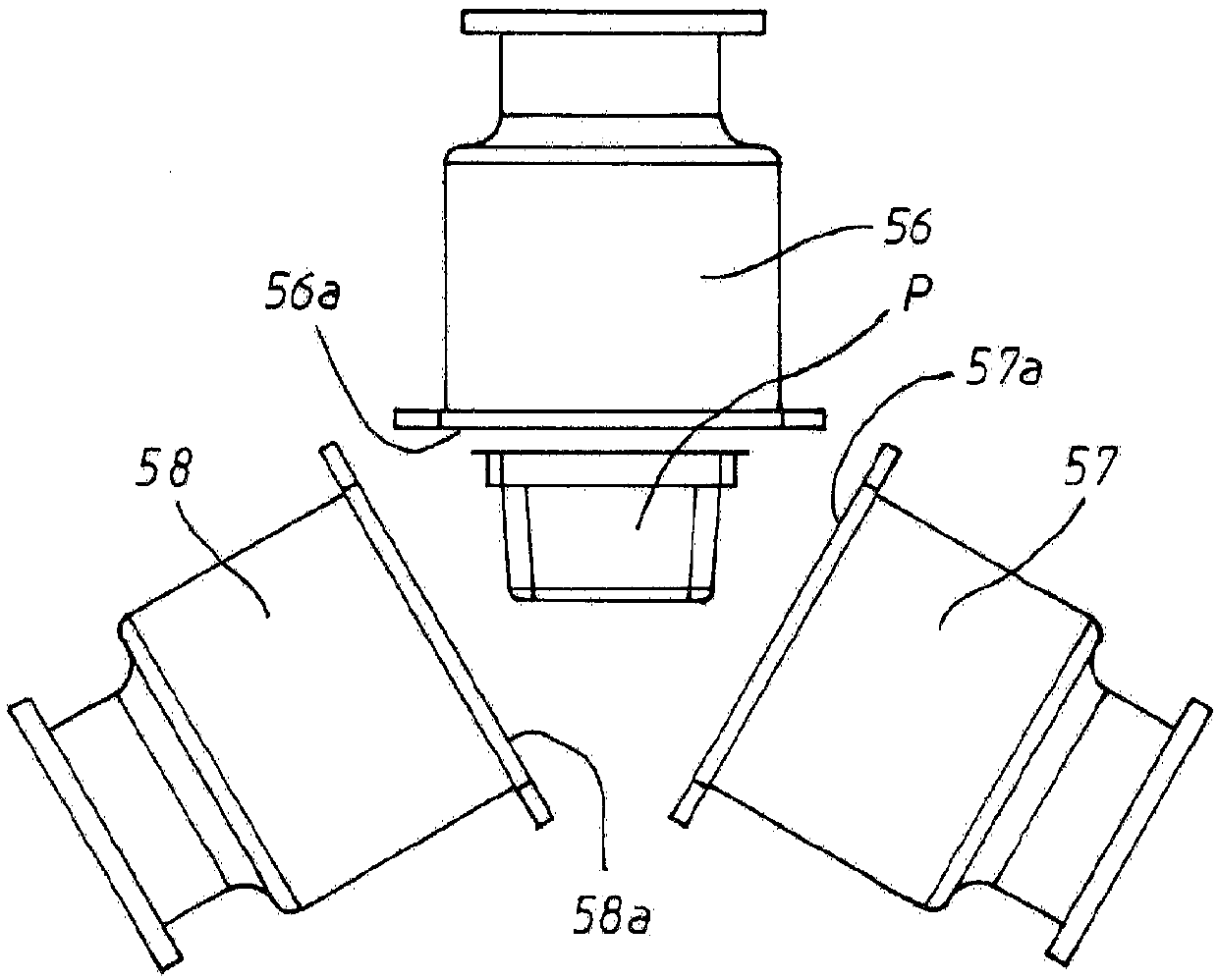

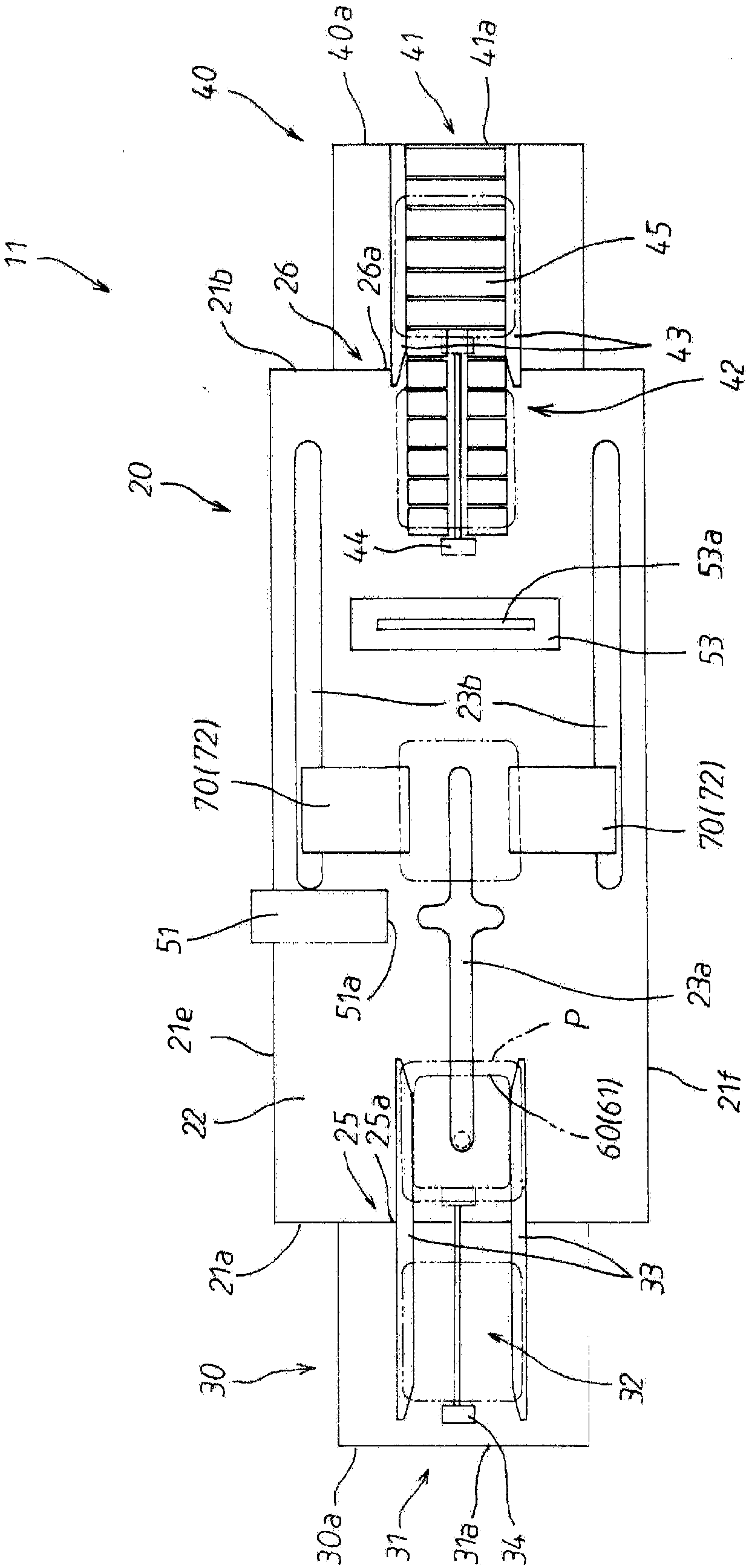

[0070] Next, an electron beam irradiation device according to the first embodiment will be described. image 3 is a schematic plan view showing the electron beam irradiation apparatus according to the first embodiment, Figure 4 It is a schematic front view showing the electron beam irradiation device. Such as image 3 and Figure 4 As shown, the electron beam irradiation device 11 according to the first embodiment is composed of an electron beam irradiation device main body 20 placed on the ground, a transfer box 30 for carrying in and a transfer box for carrying out, which are provided consecutively in front of and behind the main body 20 of the electron beam irradiation device. Box 40 constitutes.

[0071] exist image 3 and Figure 4 Among them, the periphery of the main body 20 of the electron beam irradiation apparatus is covered by outer wall parts 21 (21a to 21f) made of stainless steel metal plates, and the inside thereof is divided into an electron beam irradiat...

no. 2 approach 》

[0136] Next, an electron beam irradiation device according to the second embodiment will be described. Figure 15 is a schematic plan view showing an electron beam irradiation device according to the second embodiment, Figure 16 It is a schematic front view showing the electron beam irradiation device. Such as Figure 15 and Figure 16 As shown, similarly to the above-mentioned first embodiment, the electron beam irradiation apparatus 12 of the present second embodiment consists of an electron beam irradiation apparatus main body 20 placed on the ground and a load-in unit provided in front of and behind the electron beam irradiation apparatus main body 20. It is comprised with the transfer box 30 and the transfer box 40 for carrying out. It should be noted that the respective configurations and structures of the electron beam irradiation apparatus body 20, the transfer box 30 for loading, and the loading device 32, and the transfer box 40 for carrying out and the loading d...

no. 3 approach 》

[0170] Next, an electron beam irradiation device according to the third embodiment will be described. Figure 22 is a schematic plan view showing an electron beam irradiation apparatus according to the third embodiment, Figure 23 It is a schematic front view showing the electron beam irradiation device. Such as Figure 22 and Figure 23 As shown, similarly to the above-mentioned first embodiment, the electron beam irradiation apparatus 13 of the present third embodiment consists of an electron beam irradiation apparatus main body 20 placed on the ground and a load-in unit provided in front of and behind the electron beam irradiation apparatus main body 20. It is comprised with the transfer box 30 and the transfer box 40 for carrying out. It should be noted that the respective configurations and structures of the electron beam irradiation apparatus body 20, the transfer box 30 for carrying in and the carrying-in device 32, and the transfer box 40 for carrying out and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com