Self-dust-suction crusher

A crusher and dust-absorbing technology, applied in the field of self-cleaning crushers, can solve the problems of high energy consumption, poor dust removal effect, low work efficiency, etc., and achieve low energy consumption loss, strong suction power and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

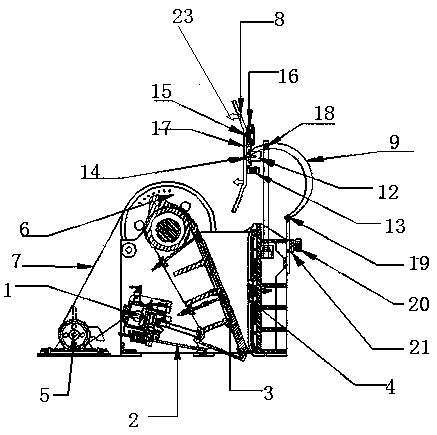

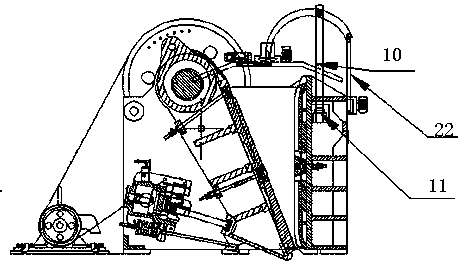

[0016] Embodiment 1: see Figure 1-Figure 2 , a self-dusting type crusher, the self-dusting type crusher includes a crushing assembly, a crusher power assembly, a dust suction cover assembly, a dust suction power assembly, and an alarm rent; the crusher power assembly is located in the crushing assembly On the left side; the dust suction cover assembly is located above the crushing assembly; the dust suction power assembly is located above the crushing assembly and is connected with the dust suction cover assembly. The design structure is simple and clear, the components are closely connected and do not affect each other, and the required parts are easy to replace and easy to maintain during the use of the product in the future. The crushing components include piston 1, hydraulic connecting rod 2, movable jaw 3 and fixed jaw 4; the piston is located on the left side of the movable jaw; the hydraulic connecting rod connects the movable jaw and the piston; the fixed jaw is locat...

Embodiment 2

[0017] Example 2: see Figure 1-Figure 2 , as an improvement of the present invention, the fan is a high-efficiency and low-noise fan. The selection of high-efficiency fans can improve the exhaust efficiency and exhaust volume of the entire system, so that this product has better market competitiveness compared with similar products. The small working noise also reduces the hearing damage to the operator, making this product more in line with the requirements of safe production.

Embodiment 3

[0018] Embodiment 3: see Figure 1-Figure 2 , as an improvement of the present invention, the fan operation assembly includes a rotating fixed gear 14, a transmission gear 15, a reduction box 16, a transmission belt 17, a fixed pulley 18, a track fixing bolt 19, a telescopic rod running motor 20, and a telescopic rod running Box 21 and telescopic rod 22; the rotating fixed gear fixes the fan casing on the top of the casing running track; the reduction box is located on the left side of the fan; the transmission gear is connected to the output end of the reduction box; the transmission gear and The fixed pulley is directly connected through the transmission belt; the track fixing bolt connects the running track of the casing with the top of the telescopic rod; the motor of the telescopic rod is located outside the running box of the telescopic rod; the telescopic rod moves up and down in the running box of the telescopic rod ; The operating box of the telescopic rod is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com