Recycling method of waste solvent in automobile industry

A recovery method and technology for waste solvent, which are applied in the field of waste solvent recovery in the automobile industry, can solve the problems that distillation cannot continue, pollute the environment, waste petroleum resources, etc., and achieve the effect of maintaining evaporation efficiency, simplifying treatment steps, and realizing recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

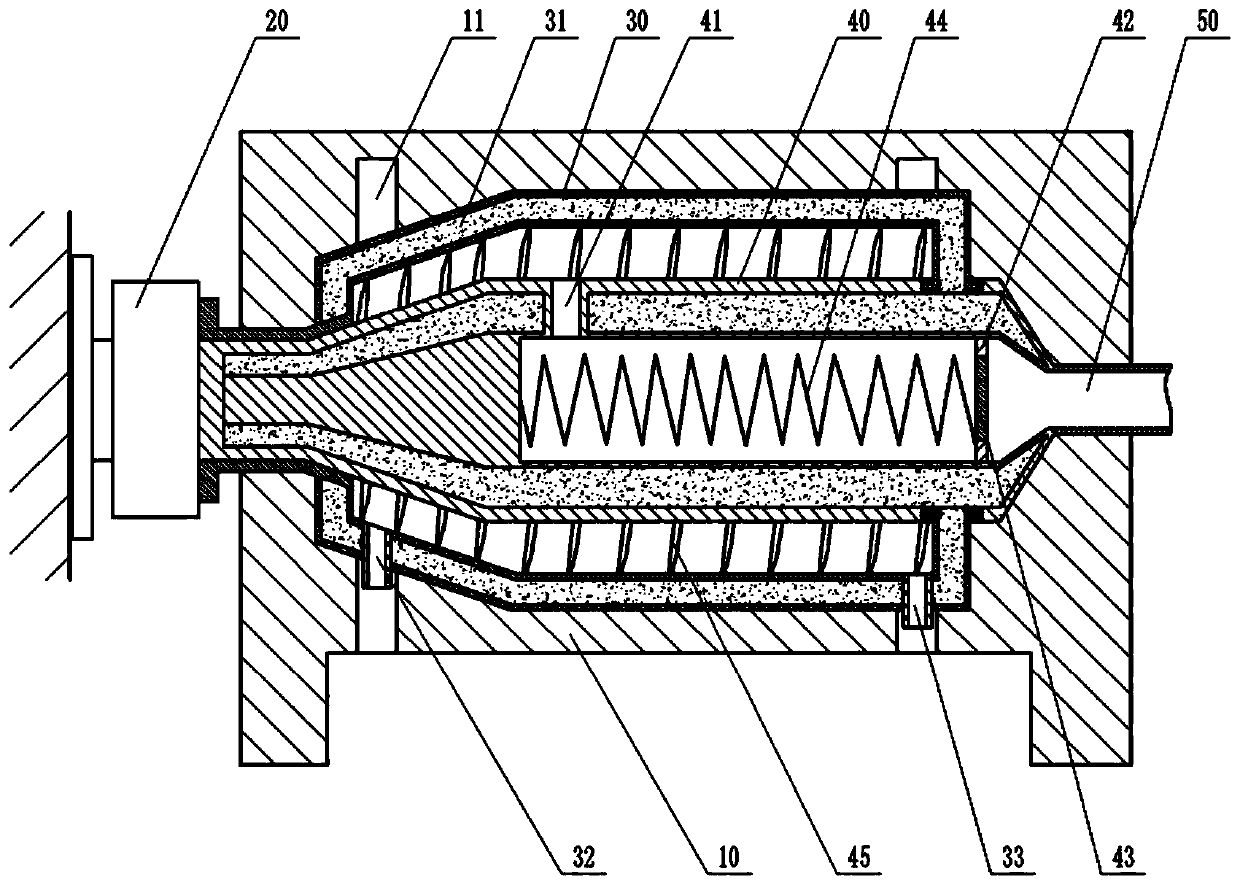

[0021] Instructions attached figure 1 The reference signs in include: base 10, annular groove 11, differential 20, drum 30, heating oil 31, solid output pipe 32, gas-liquid output pipe 33, spiral drum 40, outlet 41, scraper 42 , Pressure valve 43, spring 44, helical blade 45, feed pipe 50.

[0022] A method for recycling waste solvents in the automobile industry, comprising the following steps:

[0023] (1) Simple distillation: adopt distillation device to distill the waste solvent of automobile industry, and distillation obtains the liquid containing xylene and butyl acetate; figure 1As shown, the distillation device includes a base 10 , a drum 30 , a spiral drum 40 , a condensing unit and a differential 20 , and the differential 20 drives the drum 30 and the spiral drum 40 to rotate in the same direction at a differential speed. Both the side walls of the drum 30 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com