Technique for improving performance of aluminum alloy control arm for automobile

A process method and aluminum alloy technology, which is applied in the field of aluminum alloy process, can solve the problems of no coarse grains in the low-magnification structure of the profile, coarse grain rings in the low-magnification structure of the profile, and large temperature difference, so as to achieve uniform and sufficient cooling and improve various performance, the effect of small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

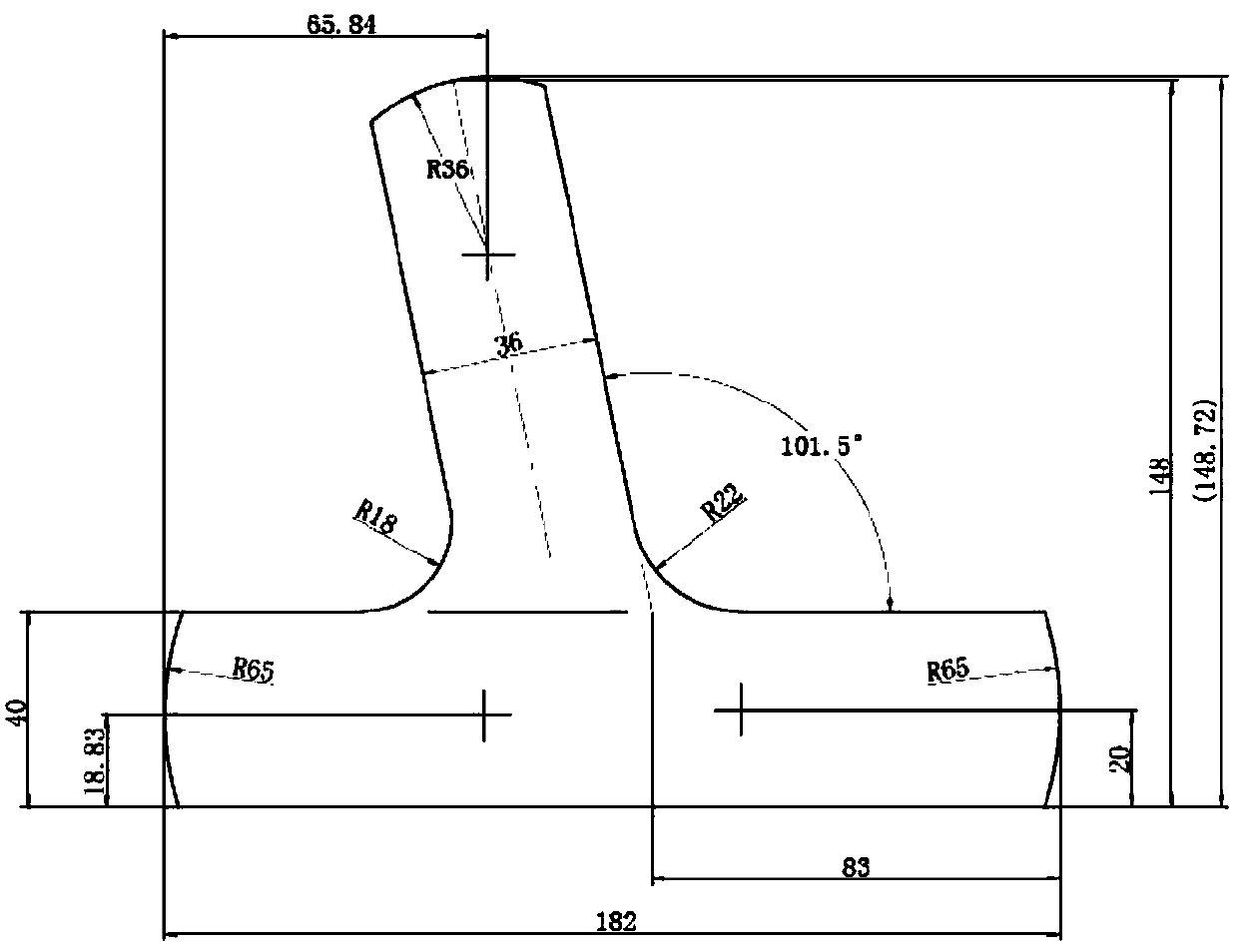

Image

Examples

Embodiment 1

[0030] A process method for improving the performance of an aluminum alloy control arm for automobiles, comprising the following steps:

[0031] A. Ingredients: aluminum alloy ingots are made according to the following mass percentages:

[0032] element

Si

Fe

Cu

mn

Mg

Cr

Ni

Zn

Ti

Al

content

1.15

0.18

0.1

0.8

0.9

0.1

0.05

0.05

0.03

margin

[0033] It also includes other single elements ≤0.03%, and the sum of other elements ≤0.1%;

[0034] B. Melting: put the prepared aluminum alloy raw materials in a melting furnace to melt into liquid aluminum alloy, and melt and cast the liquid aluminum alloy into aluminum alloy ingots. The melting temperature is 720°C, and 2% of aluminum, titanium, boron Refining agent, after the aluminum alloy raw material in the smelting furnace is completely melted, it is evenly stirred by the stirring device;

[0035] C. Homogenization treatment: homogenize the al...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that in step A, the aluminum alloy ingot is proportioned according to the following mass percentages:

[0043] element

[0044] It also includes other single elements ≤ 0.03%, and the sum of other elements ≤ 0.1%.

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is that in step A, the aluminum alloy ingot is proportioned according to the following mass percentages:

[0047] element

[0048] It also includes other single elements ≤ 0.03%, and the sum of other elements ≤ 0.1%.

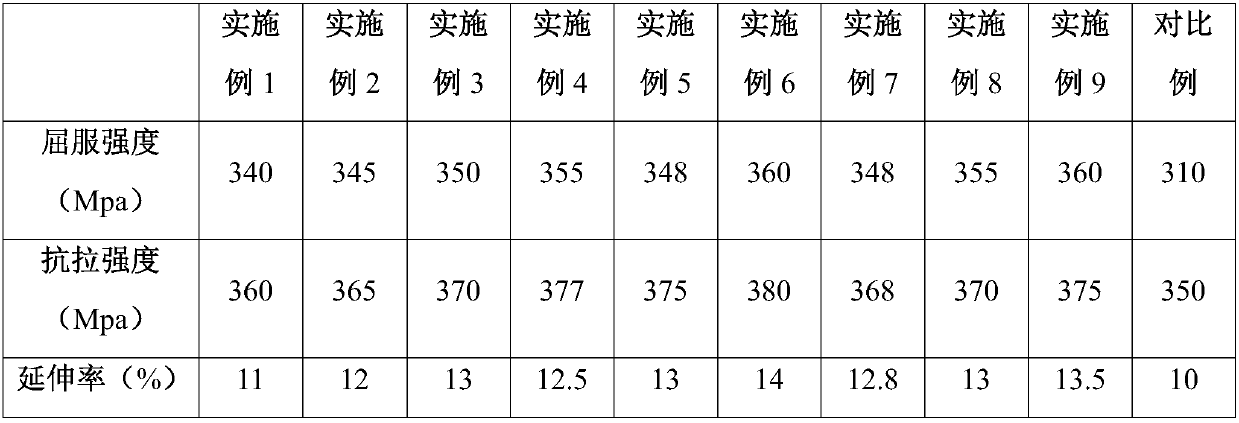

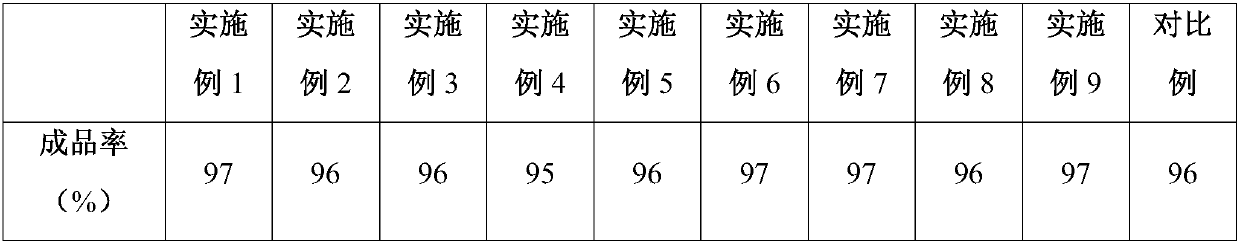

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com