Gate-type steel frame steel structure primary-secondary structure overall hoisting method

A technology of integral hoisting and portal rigid frame, which is applied in building construction, construction, and building material processing, etc., can solve the problems of poor stability of portal rigid frame, large amount of high-altitude work, increased construction cost, etc., and achieves easy inspection. , Improve work efficiency, control the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

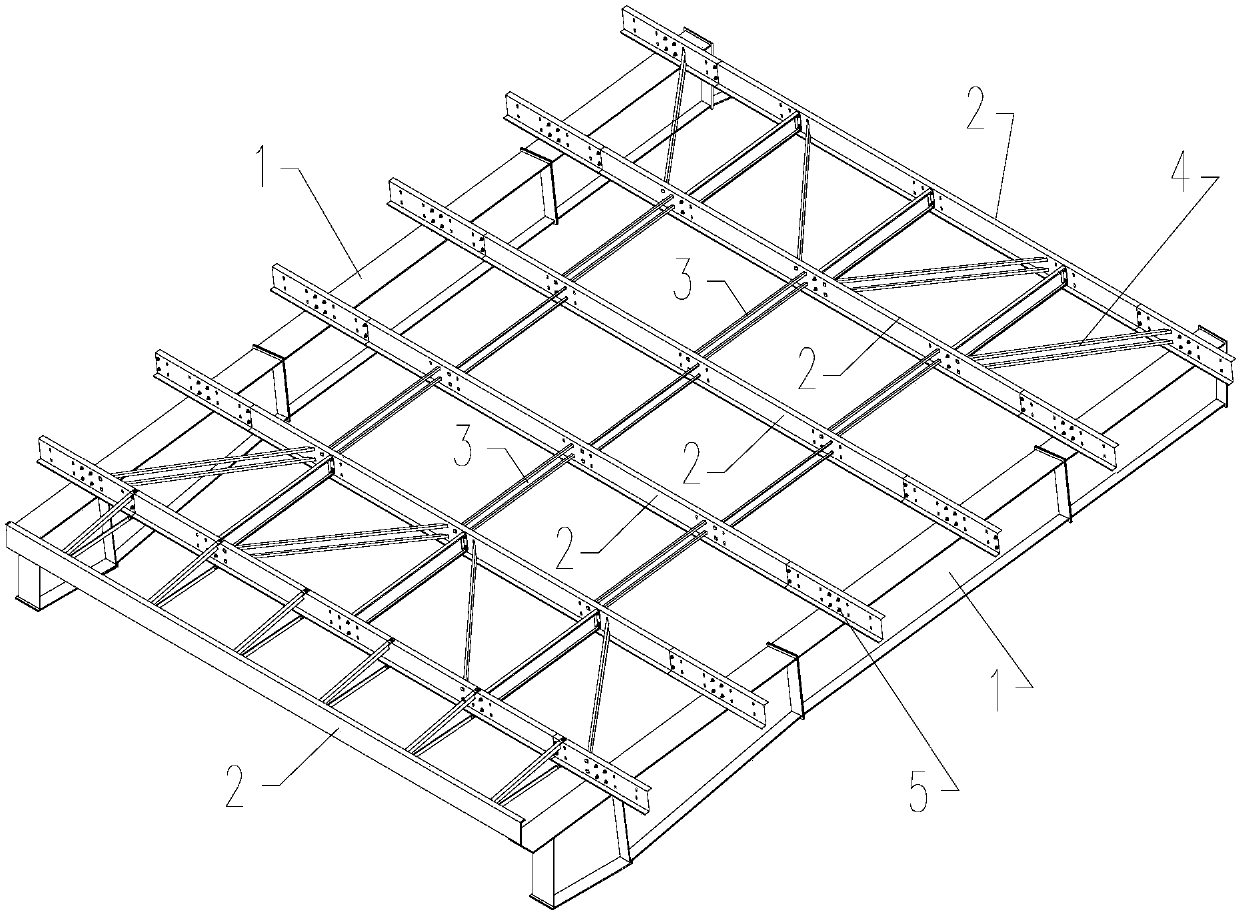

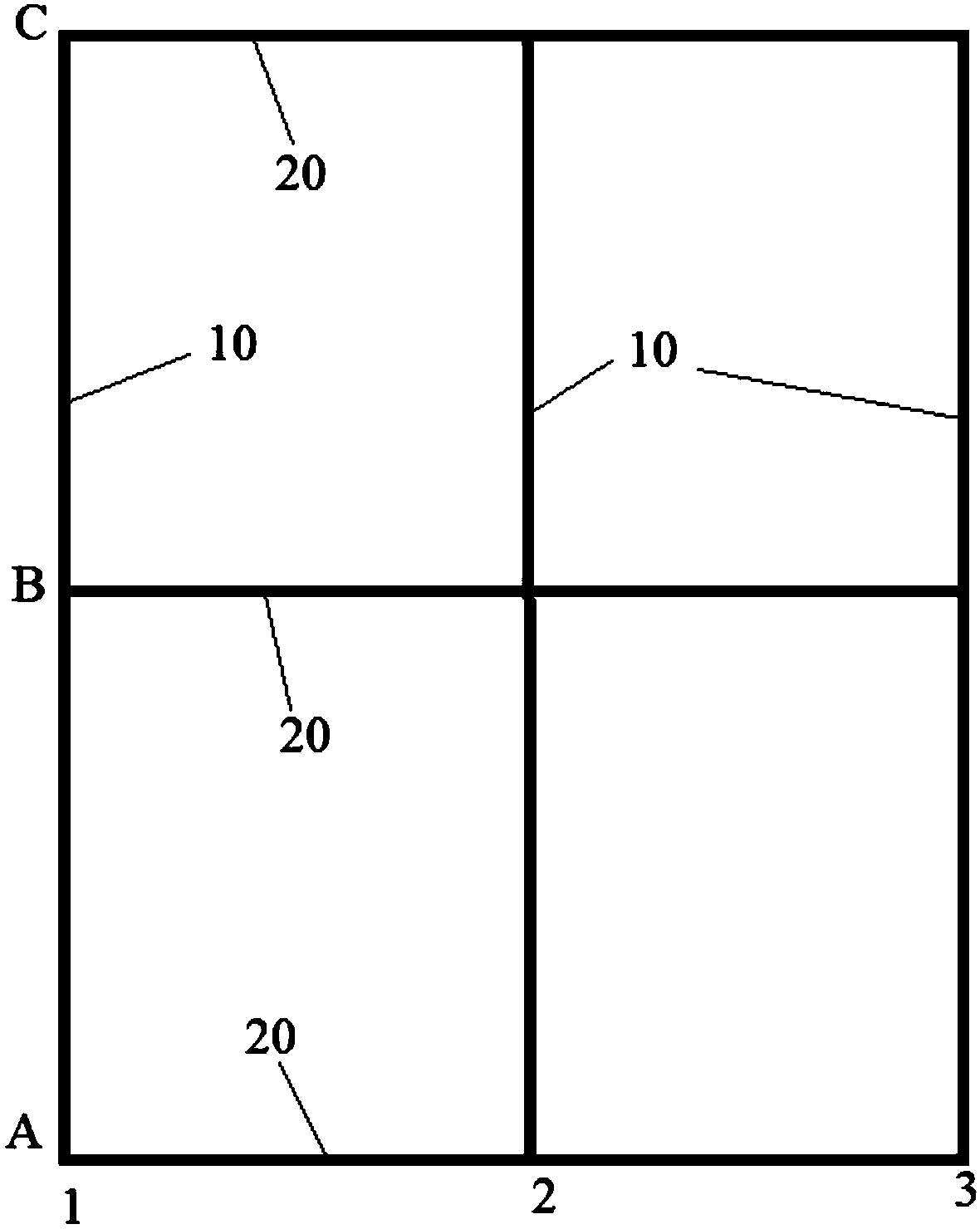

[0022] The following combination figure 1 with figure 2 , a preferred embodiment of the present invention is described in detail.

[0023] It should be noted that in this article, relational terms such as "first" and "second" are only used to distinguish one entity from another entity, and do not necessarily require or imply any such relationship between these entities. Actual relationship or sequence. It is to be understood that the terms so used are interchangeable under appropriate circumstances.

[0024] Such as figure 1 As shown, the overall hoisting method of the primary and secondary structures of the portal frame steel structure provided by the present invention includes the following steps:

[0025] S1. Complete the assembling of the portal frame steel structure with two adjacent column distances in the same span on the ground, as the overall hoisting unit of the roof; which includes in turn: assembling two steel beams 1, connecting and installing between the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com