A Calculation Method of Circulating Fluidized Bed Boiler Performance Based on Calcium Balance

A technology of circulating fluidized bed and boiler performance, applied in the direction of design optimization/simulation, etc., can solve problems such as reducing test uncertainty and reducing measurement work, and achieve the effect of eliminating large measurement uncertainty, convenient and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

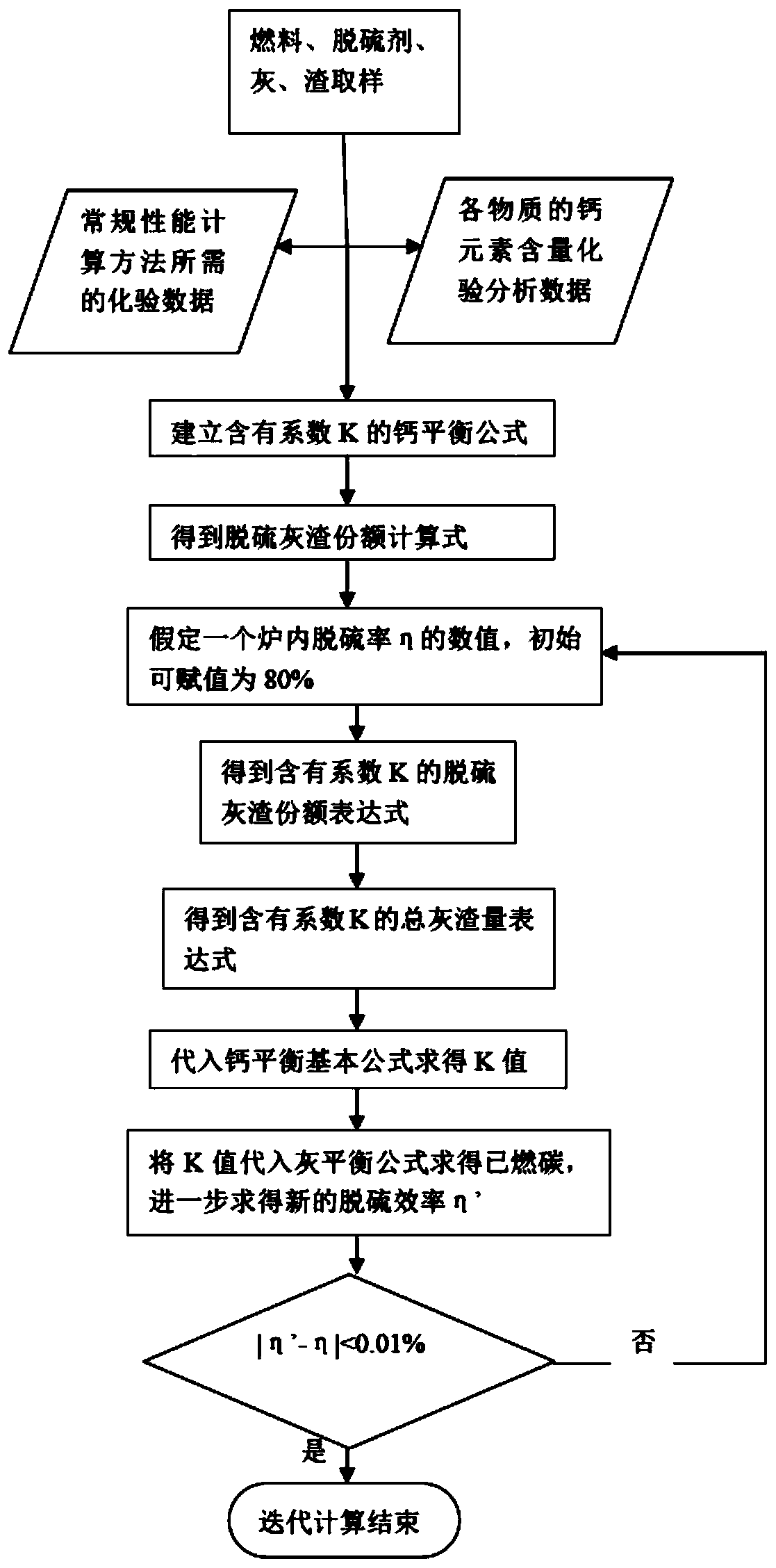

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0059] see figure 1 , a calcium balance-based CFB performance calculation method of the present invention, comprising the following steps:

[0060] According to the method stipulated in GB10184-2015 "Power Plant Boiler Performance Test Regulations", the furnace fuel, desulfurizer, fly ash and bottom slag were sampled respectively;

[0061] Laboratory analysis of calcium content in fuel and desulfurizer entering the boiler boundary;

[0062] Laboratory analysis of calcium content in fly ash and bottom slag leaving the boiler boundary;

[0063] Determine the proportion of ash and slag by test method measurement;

[0064] Based on the conservation of calcium element, the basic formula for calcium balance of circulating fluidized bed boiler is:

[0065] (Ca) 燃料 +K·(Ca) 脱硫剂 =(Ca) 总灰渣

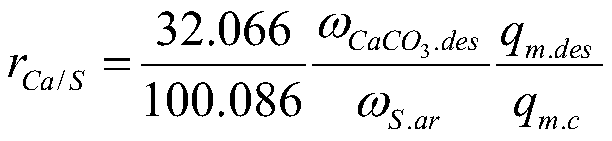

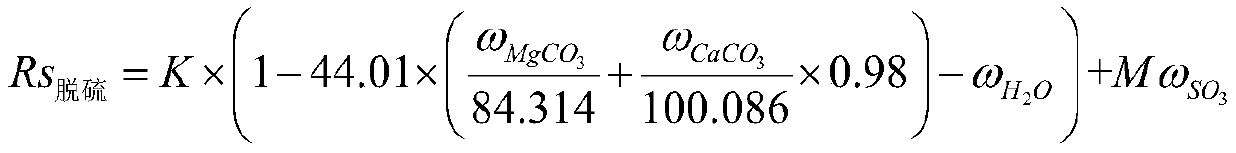

[0066] In the formula: K is the mass ratio of desulfurizer to fuel, ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com