High efficiency extraction method of bambusa cerosissima fibers

An extraction method and bamboo fiber technology are applied in the field of single bamboo fiber extraction and bamboo fiber extraction, which can solve the problems that bacteria cannot reproduce and cannot survive, and achieve the effects of simple operation, improved production efficiency, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

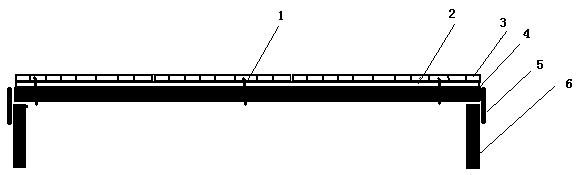

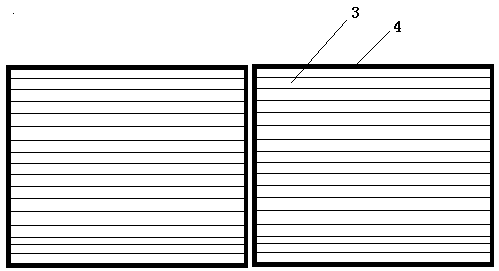

[0015] The extraction method of a kind of high-efficiency single bamboo fiber is to carry out according to the following steps: 1. Remove the branches, tips and roots of the bamboo, scrape off the green bamboo, and saw it into a bamboo tube of a certain length. Split into bamboo slices with a width of about 2 cm, soak the bamboo slices in a special NaOH degumming softener, the concentration of the degumming softener is 30% to 40%, and the soaking time is 30 to 50 hours; 2. Wash the soaked bamboo slices Clean, flatten the bamboo slices with a machine, then dissect them into crude fibers with a silk machine, and then rinse with water to remove the colloids; 3. Put the crude fibers into a cooking pot, add water to immerse, and heat to above 100°C for 2~ For 3 hours, separate the fibers and lignin, colloid and other adherents by stirring, rinse with water after pulling out, and remove impurities such as colloids to obtain bamboo fibers; Soak the additives for 1-2 hours to soften, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com