Graphene oxide composite film material, and preparation method and application thereof

A graphene composite, thin film material technology, applied in chemical instruments and methods, synthetic resin layered products, substructures, etc., can solve the problems of poor adhesion, high barrier layer materials, etc., to reduce the number of layers, high Barrier performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

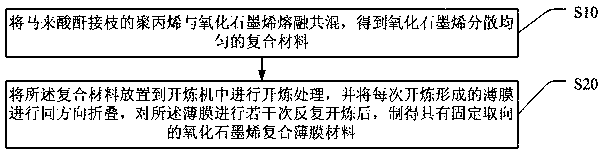

[0038] 45g of maleic anhydride grafted polypropylene (MAPP) and 5g of graphene oxide (MLGO) were melt blended in an internal mixer to obtain a composite material MAPP / 10%MLGO with uniform dispersion of graphene oxide, and the blending temperature was 120 ℃~140℃, the rotation speed is 50 rpm, the blending time is 10-15min, and granulate after blending evenly;

[0039] 4g of the prepared composite material MAPP / 10%MLGO was kneaded in an open mill to form a thin film with a thickness of less than 100 μm, folded in the same direction and then kneaded repeatedly for about 5 times. The kneading temperature was 148°C. Oriented graphene oxide composite film material with a thickness of about 40 μm;

[0040] Stack four films, heat them to 120°C in a flat vulcanizer, apply 10MPa, keep for 2min, and after cooling, a MAPP / 10%MLGO sheet of about 160μm is obtained.

Embodiment 2

[0042]45g of maleic anhydride grafted polypropylene (MAPP) and 5g of graphene oxide (MLGO) were melt blended in an internal mixer to obtain a composite material MAPP / 10%MLGO with uniform dispersion of graphene oxide, and the blending temperature was 120 ℃~140℃, the rotation speed is 50 rpm, the blending time is 10-15min, and granulate after blending evenly;

[0043] 4g of MAPP was kneaded in an open mill to form a film below 100 μm at a temperature of 150 °C; 4 g of the prepared composite material MAPP / 10%MLGO was kneaded in an open kneader to form a film below 100 μm. Two pieces of 2g MAPP film and 1g MAPP / 10%MLGO film are stacked in a "sandwich" structure (the MAPP film is the inner and outer layers, and the MAPP / 10%MLGO film is the middle layer), and they are kneaded in an open mill to form The film below 100 μm is folded in the same direction and then kneaded repeatedly for about 10 times. The kneading temperature is 148°C, and the graphene oxide composite film material MA...

Embodiment 3

[0046] 45g of maleic anhydride grafted polypropylene (MAPP) and 5g of graphene oxide (MLGO) were melt blended in an internal mixer to obtain a composite material MAPP / 10%MLGO with uniform dispersion of graphene oxide, and the blending temperature was 120 ℃~140℃, the rotation speed is 50 rpm, the blending time is 10-15min, and granulate after blending evenly;

[0047] 4g of the prepared composite material MAPP / 10%MLGO was kneaded in an open mill to form a thin film of 100 μm or less, folded in the same direction and then kneaded repeatedly for about 10 times at a kneading temperature of 148°C. Oriented graphene oxide composite film material with a thickness of about 40 μm;

[0048] Stack four films, heat them to 120°C in a flat vulcanizer, apply 10MPa, keep for 2min, and after cooling, a MAPP / 10%MLGO sheet of about 160μm is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com