A Proportioning Method of Void Concrete

A technology of void and mix ratio, applied in data processing applications, instruments, complex mathematical operations, etc., can solve the problems of lack, the reasonable volume of the clean slurry cannot be guaranteed, lack of scientificity or rationality, etc., to reduce the volume and dryness. shrink, improve work performance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

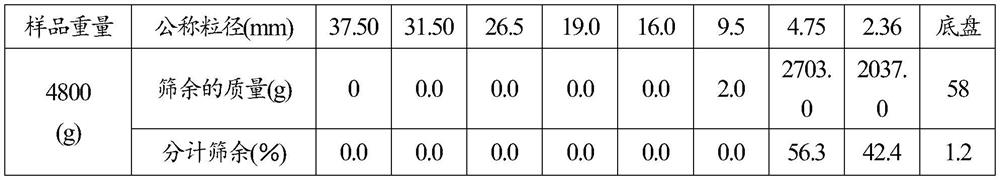

[0146] A method for proportioning void concrete, which requires the preparation of porosity not less than 20%, water permeability >1.0, strength grade C30, mixing on site, initial setting time not less than 1 hour, final setting time not less than 2 hours, and Fly ash is as admixture, and described proportioning method comprises the following steps:

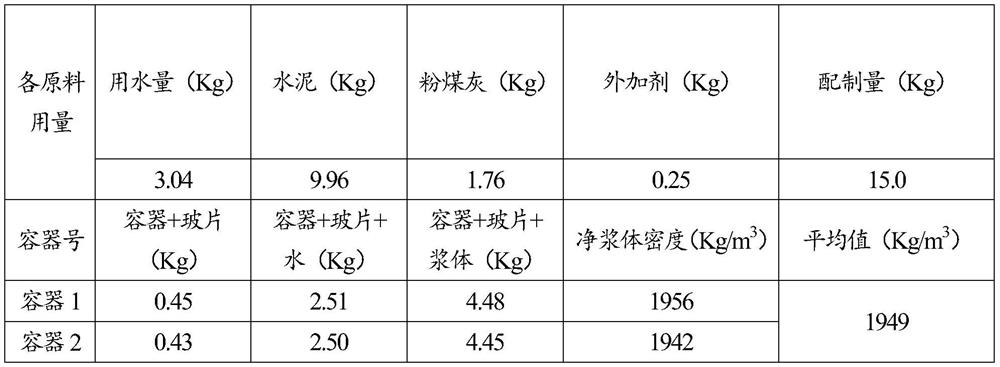

[0147] (1) Initially determine the net slurry and measure the density:

[0148] 1. Select the raw materials for the net slurry: cement, water, fly ash, admixture, the cement uses ordinary Portland cement with a strength grade of 42.5, the water uses drinking water, and the fly ash uses grade I fly ash, plus The agent is polycarboxylate water reducer.

[0149] 2. Determination of raw material indicators: the standard deviation statistics are 5 according to the specification, the cement strength is 42.5Mpa, the affluence coefficient statistics are 1.1, the 28-day compressive strength of cement = 42.5*1.1 = 46.75Mpa, the test deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com