Proportioning method for gap concrete

A technology of void and mix ratio, applied in complex mathematical operations, instruments, data processing applications, etc., can solve problems such as lack of scientificity or rationality, inability to guarantee a reasonable volume of clean slurry, and lack of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

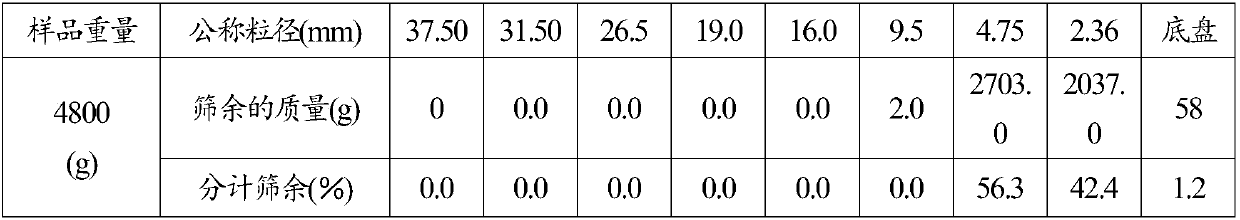

[0146] A method for proportioning void concrete, which requires the preparation of porosity not less than 20%, water permeability >1.0, strength grade C30, mixing on site, initial setting time not less than 1 hour, final setting time not less than 2 hours, and Fly ash is as admixture, and described proportioning method comprises the following steps:

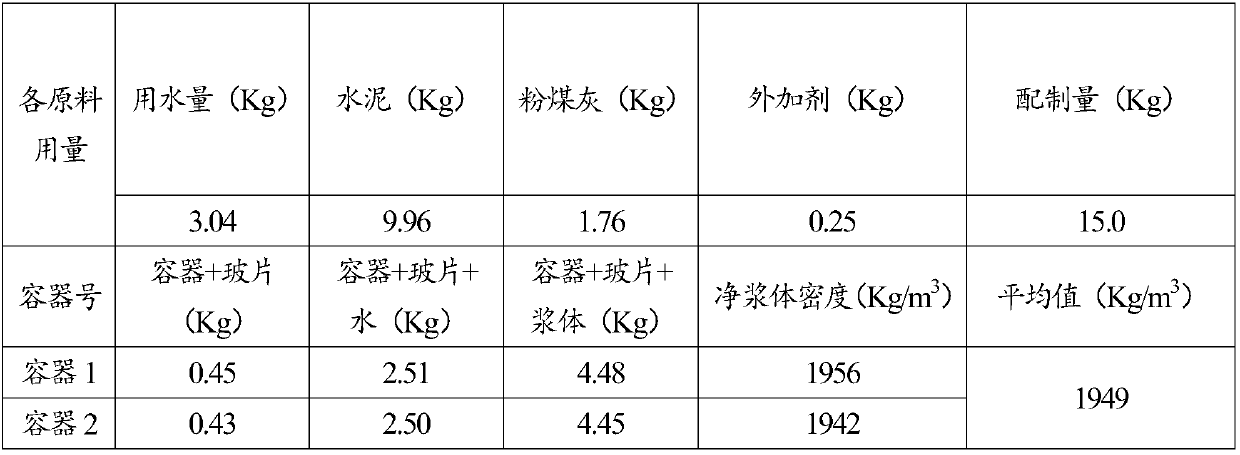

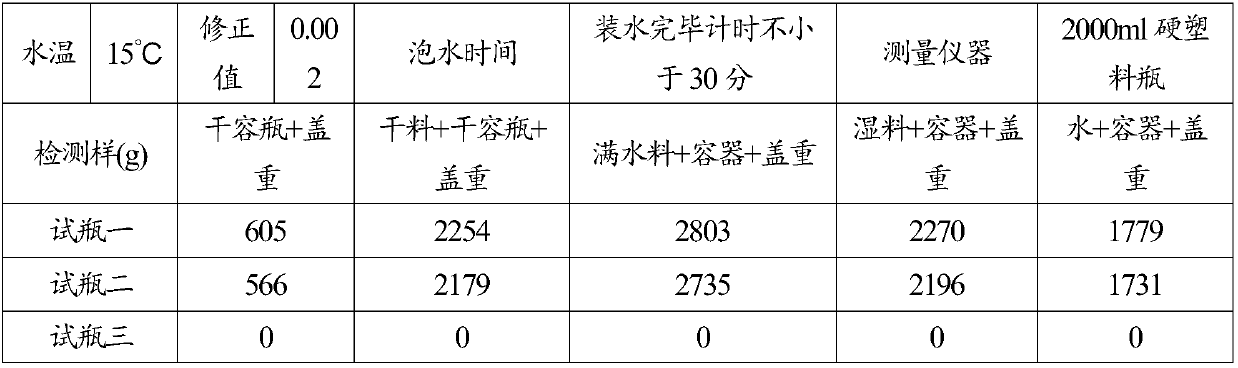

[0147] (1) Initially determine the net slurry and measure the density:

[0148] 1. Select the raw materials for the net slurry: cement, water, fly ash, admixture, the cement uses ordinary Portland cement with a strength grade of 42.5, the water uses drinking water, and the fly ash uses grade I fly ash, plus The agent is polycarboxylate water reducer.

[0149] 2. Determination of raw material indicators: the standard deviation statistics are 5 according to the specification, the cement strength is 42.5Mpa, the affluence coefficient statistics are 1.1, the 28-day compressive strength of cement = 42.5*1.1 = 46.75Mpa, the test deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com