A high-energy-density silicon-carbon battery that does not expand at high temperature

A high-energy density, battery technology, applied in secondary batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems affecting battery cycle and storage performance, increasing battery use costs, and battery SEI thickness, etc. The effect of gas production, reduction in usage, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

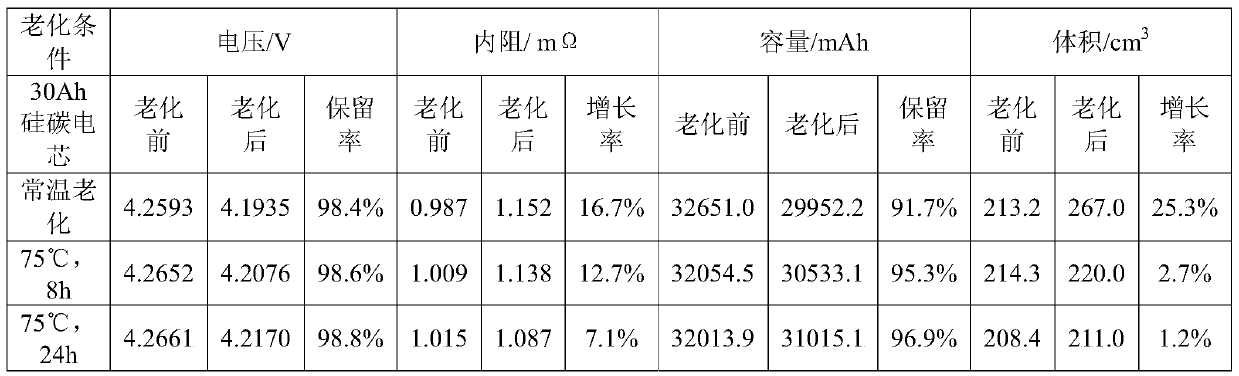

Image

Examples

Embodiment 1

[0022] A high-energy density silicon-carbon battery that does not expand at high temperature. The electrolyte includes: electrolyte lithium salt, solvent and additives.

[0023] The electrolyte lithium salt is a mixture of lithium hexafluorophosphate and lithium difluorooxalate borate, and the concentration of lithium hexafluorophosphate is 1.1 mol / L, and the concentration of lithium difluorooxalate is 1.1 mol / L.

[0024] The volume ratio of the solvent includes: EC accounts for 25%, EMC accounts for 60%, DMC accounts for 10%, and FEC accounts for 5%.

[0025] The additives include methylene disulfonate, tris(trimethyl)silane borate and vinylene carbonate, and the concentration of methylene disulfonate is 0.5wt%, tris(trimethyl)silane The concentration of borate is 0.2% by weight, and the concentration of vinylene carbonate is 1% by weight.

[0026] The formation process of the silicon carbon battery is as follows: sequentially charge with currents of 0.01C, 0.02C, and 0.05C for 30 mi...

Embodiment 2

[0028] A high-energy density silicon-carbon battery that does not expand at high temperature. The electrolyte includes: electrolyte lithium salt, solvent and additives.

[0029] The electrolyte lithium salt is a mixture of lithium hexafluorophosphate and lithium difluorooxalate borate, and the concentration of lithium hexafluorophosphate is 0.9 mol / L, and the concentration of lithium difluorooxalate is 0.9 mol / L.

[0030] The volume ratio of the solvent includes: EC accounts for 30%, EMC accounts for 55%, DMC accounts for 12%, and FEC accounts for 3%.

[0031] The additives include methylene disulfonate, tris(trimethyl)silane borate and vinylene carbonate, and the concentration of methylene disulfonate is 0.4wt%, tris(trimethyl)silane The concentration of borate is 0.15 wt%, and the concentration of vinylene carbonate is 0.9 wt%.

[0032] The formation process of the silicon carbon battery is as follows: sequentially charge with currents of 0.01C, 0.02C, and 0.05C for 28 minutes; then...

Embodiment 3

[0034] A high-energy density silicon-carbon battery that does not expand at high temperature. The electrolyte includes: electrolyte lithium salt, solvent and additives.

[0035] The electrolyte lithium salt is a mixture of lithium hexafluorophosphate and lithium difluorooxalate borate, and the concentration of lithium hexafluorophosphate is 1.2 mol / L, and the concentration of lithium difluorooxalate is 1.2 mol / L.

[0036] The volume ratio of the solvent includes: EC accounts for 20%, EMC accounts for 65%, DMC accounts for 11%, and FEC accounts for 4%.

[0037] The additives include methylene disulfonate, tris(trimethyl)silane borate and vinylene carbonate, and the concentration of methylene disulfonate is 0.6wt%, tris(trimethyl)silane The concentration of borate is 0.25 wt%, and the concentration of vinylene carbonate is 1.1 wt%.

[0038] The formation process of the silicon carbon battery is as follows: sequentially charge with currents of 0.01C, 0.02C, and 0.05C for 32 minutes; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com