Building reserved steel bar cut off device

A technology for reserving steel bars and cutting devices, which is applied in the field of building construction, can solve the problems of uneven stress on steel bars, variable heights, uncontrollable arms, etc., and achieves the effects of improving uniformity, simple structure and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

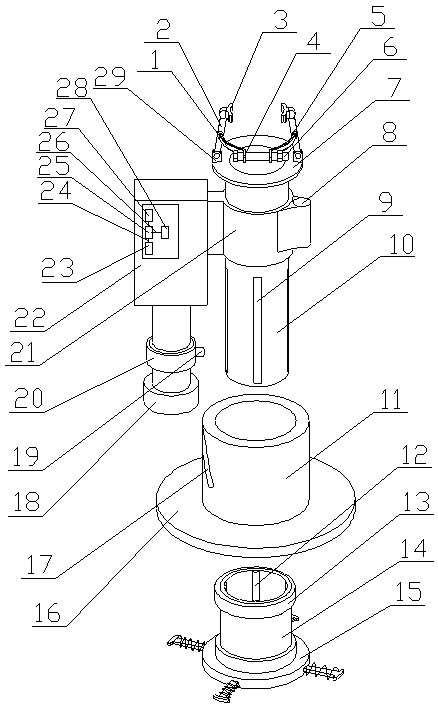

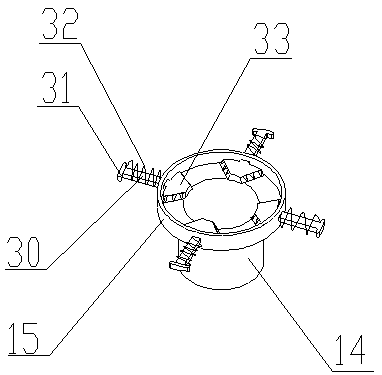

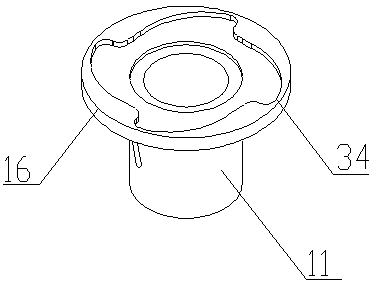

[0031] A device for cutting reserved steel bars for construction in the present invention is realized in this way. When using, when cutting the reserved steel bars, firstly, the fixed cylinder (10) is sleeved on the reserved steel bars, and the rotating disc (16) and The cutting position of the steel bar is corresponding, and then by tightening the bolts, the two pressure blocks (3) are pressed on both sides of the steel bar; the driving motor (22) drives the fixed gear (18) to rotate, and the fixed gear (18) drives the gear sleeve ( 11) Turn, the gear sleeve (11) drives the rotating disc (16) to rotate, the rotating disc (16) drives the rotating groove (34) to rotate, the rotating groove (34) and the four connecting plates rotate relative to each other, and one end of the connecting plate moves from the peak When turning to the trough, the four connecting plates respectively drive the connected cutters (33) to shrink, the springs (32) on the connecting plates are compressed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com