Device and method for digging out roadbed filler single holes

A technology of roadbed filler and roadbed, which is applied in drilling equipment and methods, support devices, earthwork drilling, etc., can solve problems such as limited working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is introduced below by accompanying drawing.

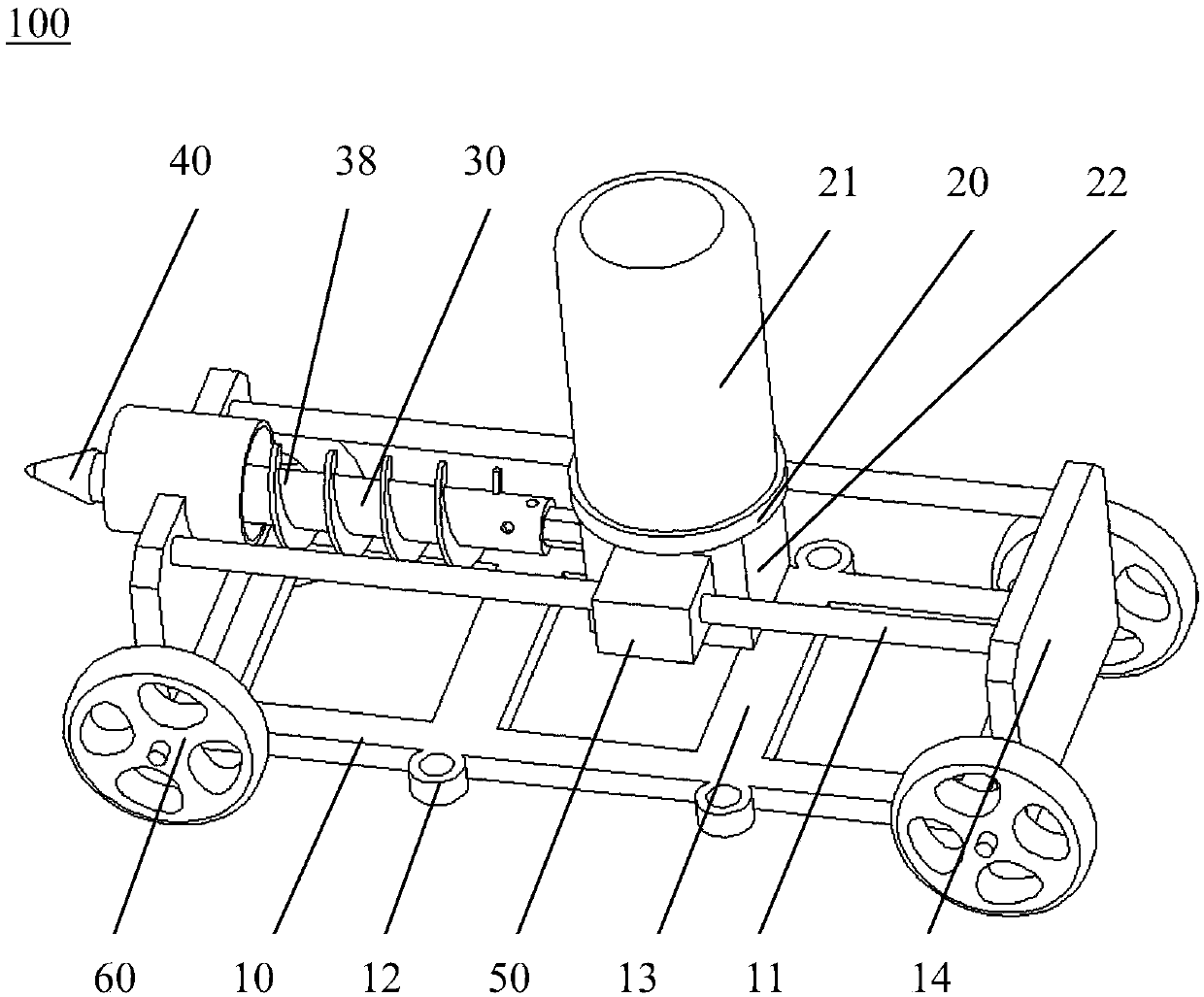

[0030] figure 1 The structure of an excavation device 100 for excavating a single hole for roadbed filling according to the present invention is shown. Such as figure 1 As shown, the digging device 100 includes a frame 10 . The frame 10 includes a frame body 13, and the frame body 13 is in the shape of a rectangular plate. A support plate 14 is provided on the edge of the upper end surface of the frame body 13 , and the support plate 14 is arranged on opposite short sides of the frame body 13 . A plurality of guide posts 11 are arranged between the support plates 14 , the guide posts 11 are above the frame body 13 and on the same horizontal plane, and the guide posts 11 are parallel to each other. For example, in figure 1 In the illustrated embodiment, the frame 10 is provided with two guide posts 11 . The structure of the rack 10 is simple, easy to install, and low in manufacturing cost.

[003...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap