A device for rapidly separating and collecting cr(vi) in the field

A fast and field technology, applied in the direction of measuring devices, analysis materials, test sample preparation, etc., can solve the problems of unscientific environmental pollution, lower test accuracy, cumbersome operation steps, etc., achieve low cost and wide application range , Simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

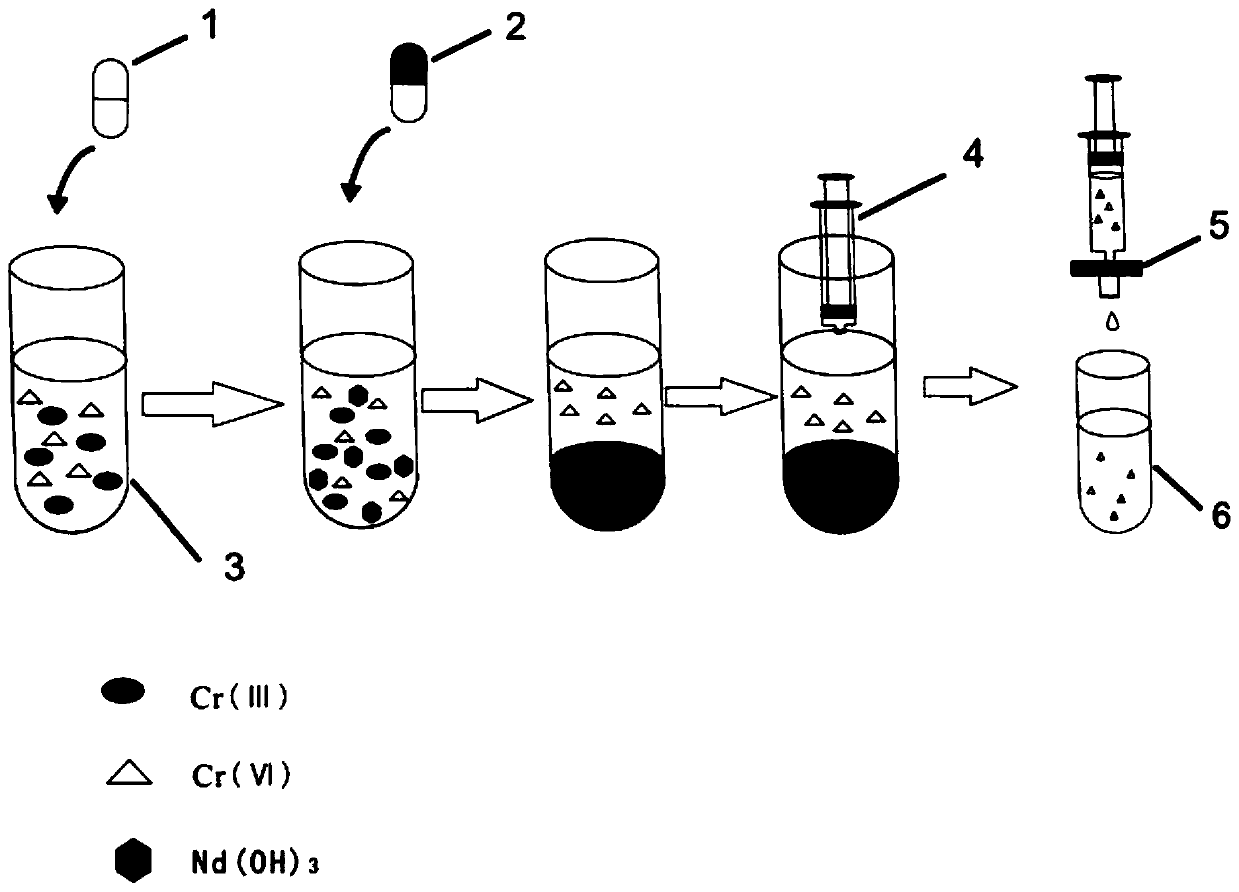

[0017] Please refer to figure 1 , The embodiment of the present invention provides a device for rapidly separating and collecting Cr(VI) in the field, including a co-precipitation capsule 1, a sodium hydroxide capsule 2, a test tube 3, a syringe 4, a filter device 5, and a receiving cup 6.

[0018] Nd(NO 3 ) 3 ·6H 2 O, NaOH is housed in the sodium hydroxide capsule 2. In one embodiment, the co-precipitation capsule 1 and the sodium hydroxide capsule 2 are made of tapioca starch.

[0019] The test tube 3 contains samples collected in the field. In one embodiment, the capacity of the test tube 3 is 50 mL.

[0020] The capacity of syringe 4 is 10mL, and the supernatant liquid that described syringe 4 once draws is 5-10mL, and described filter device 5 is connected at the outlet of syringe 4, and filter device 5 is a filter membrane, and the aperture of described filter membrane is preferably is 0.22 μm.

[0021] Open co-precipitation capsule 1 and sodium hydroxide capsule 2,...

Embodiment 2

[0030] Take 20mL surface water sample in 50mL test tube 3, add Cr(Ⅵ) standard liquid 10μgL -1 To simulate field surface water, add 1mgNd(NO 3 ) 3 ·6H 2 O, stir to dissolve, add 20mg sodium hydroxide, let stand for 5min. Use a 10 mL syringe 4 to draw 5 mL of the solution, filter it through a filter membrane with a pore size of 0.22 μm, and collect the filtrate with a receiving cup 6 . Chromium is detected by ICP-MS, which is the Cr(Ⅵ) content. The recovery rate of Cr(Ⅵ) was 92.4%.

Embodiment 3

[0032] Take 20mL drinking water sample in 50mL test tube 3, add Cr(Ⅵ) standard liquid 10μgL -1 To simulate wild drinking water, add 0.1mgNd(NO 3 ) 3 ·6H 2 O, stir to dissolve, add 25mg of sodium hydroxide, let stand for 5min. Draw 5mL of the solution with a 10mL syringe 4, filter through a filter membrane with a pore size of 0.22μm, and collect the filtrate with a receiving cup. Chromium is detected by ICP-MS, which is the Cr(Ⅵ) content. The recovery rate of Cr(Ⅵ) was 94.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com