Methods to reduce the harm of flue-cured tobacco "high temperature forced ripening"

A technology of flue-cured tobacco and high temperature is applied in the field of metabolic regulation mechanism of flue-cured tobacco to achieve the effects of optimizing the sugar-to-alkali ratio, enhancing stress resistance, and increasing the content of total sugar and reducing sugar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

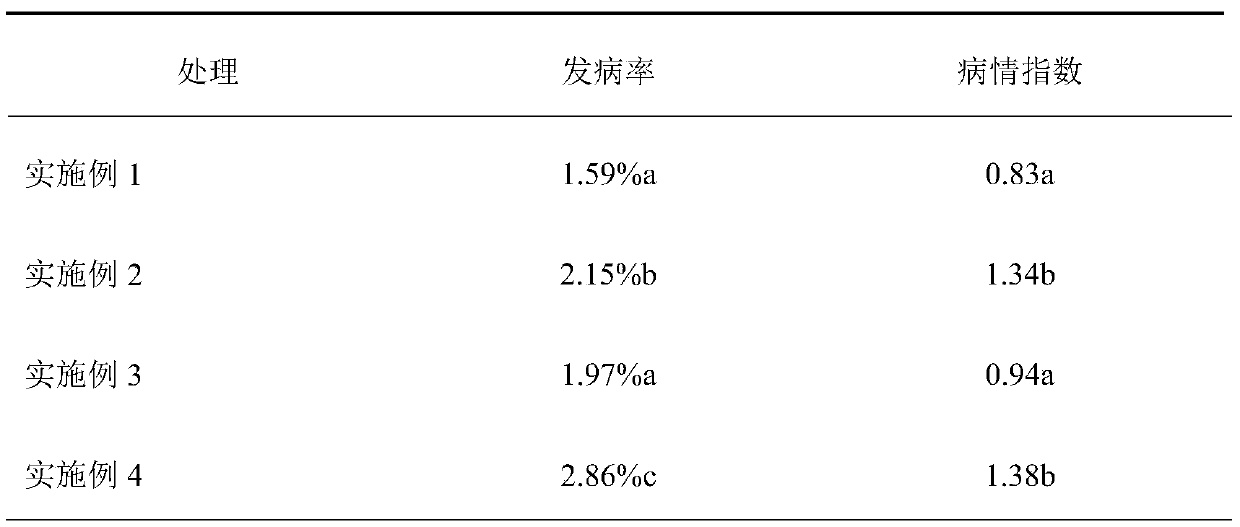

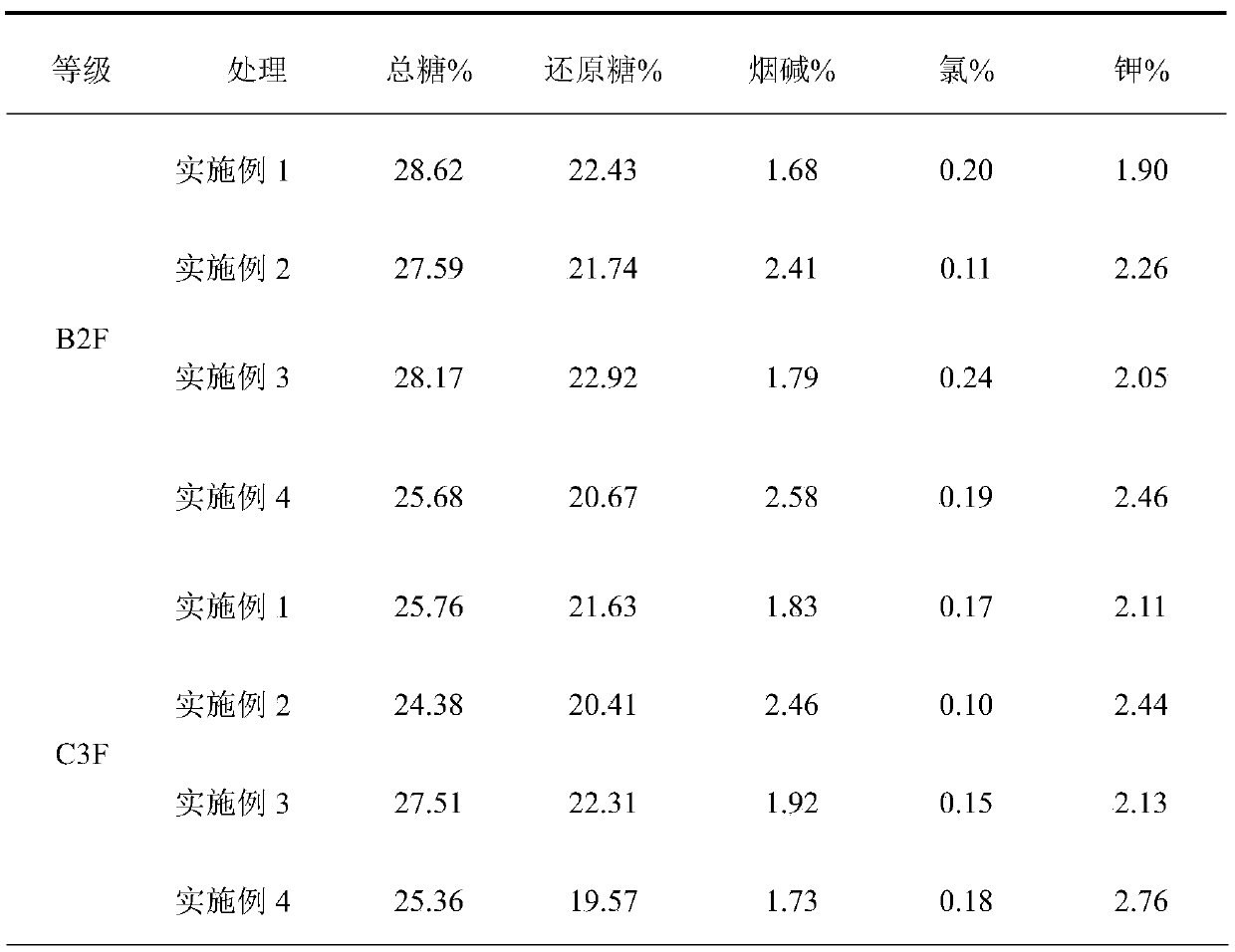

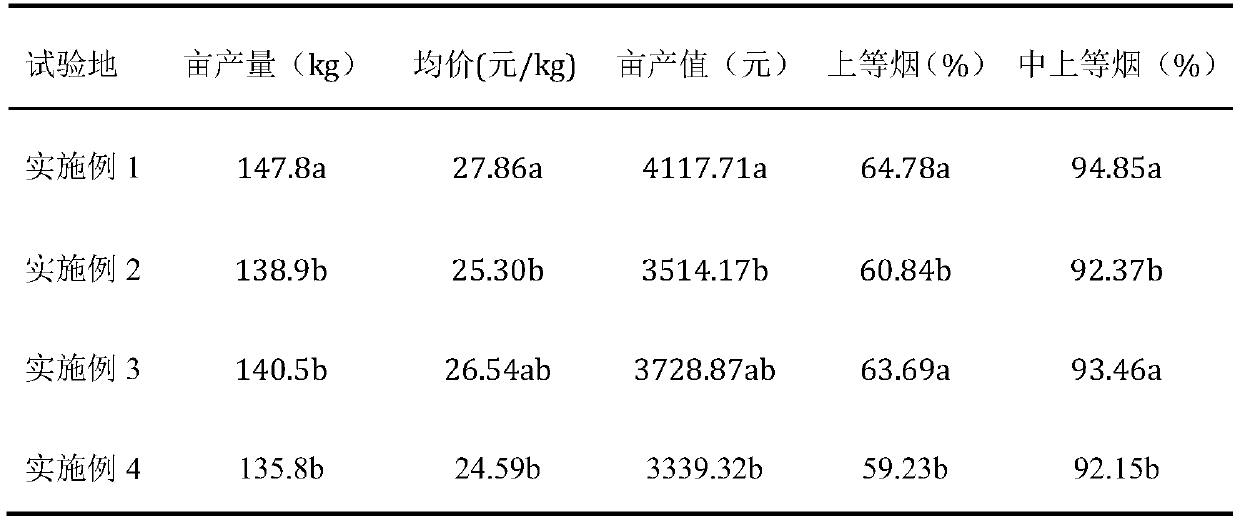

Examples

Embodiment 1

[0016] A method for reducing the hazards of "high temperature forced ripening" of flue-cured tobacco, including spraying light damage prevention and control agents, strengthening secondary metabolism of tobacco plants during the maturation stage, and coordinated control of the three factors of light, temperature, and humidity in the late stage of flue-cured tobacco maturation;

[0017] The photodamage prevention and control agent is 20mmol L -1 CaCl 2 ;The method of use is: normal cultivation and management conditions + light damage prevention and control, light damage control is sprayed on the leaves in the early stage of maturity;

[0018] The method for strengthening the secondary metabolism in the mature stage of the tobacco plant is to spray a secondary metabolism inducer in the mature stage of the tobacco strain: the secondary metabolism inducer is 100 mg·L -1 Salicylic acid; applied by spraying method; foliage sprayed twice at maturity and 10 days before harvest;

[0...

Embodiment 2

[0021] A method for reducing the hazards of "high temperature forced ripening" of flue-cured tobacco, including spraying light damage prevention and control agents, strengthening secondary metabolism of tobacco plants during the maturation stage, and coordinated control of the three factors of light, temperature, and humidity in the late stage of flue-cured tobacco maturation;

[0022] The photodamage prevention and control agent is 15mmol L -1 CaCl 2 ;The method of use is: normal cultivation and management conditions + light damage prevention and control, and the light damage prevention and control agent is sprayed on the leaves in the early stage of maturity;

[0023] The method for strengthening the secondary metabolism of the tobacco strain at the mature stage is to spray a secondary metabolism inducer at the mature stage of the tobacco strain: the secondary metabolism inducer is 1 mg·L -1 Epibrassinolide; applied by spraying method; spray 2 times on leaves at maturity an...

Embodiment 3

[0026] A method for reducing the hazards of "high temperature forced ripening" of flue-cured tobacco, including spraying light damage prevention and control agents, strengthening secondary metabolism of tobacco plants during the maturation stage, and coordinated control of the three factors of light, temperature, and humidity in the late stage of flue-cured tobacco maturation;

[0027] The photodamage prevention and control agent is 25mmol L -1 CaCl 2 ;The method of use is: normal cultivation and management conditions + light damage prevention and control, and the light damage prevention and control agent is sprayed on the leaves in the early stage of maturity;

[0028] The method for strengthening the secondary metabolism in the mature stage of the tobacco plant is to spray a secondary metabolism inducer in the mature stage of the tobacco strain: the secondary metabolism inducer is 100 mg·L -1 Salicylic acid; applied by spraying method; foliage sprayed twice at maturity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com