Horizontal four-roller part rolling mill

A roller and horizontal technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., to achieve the effects of simplifying equipment structure, improving quality, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

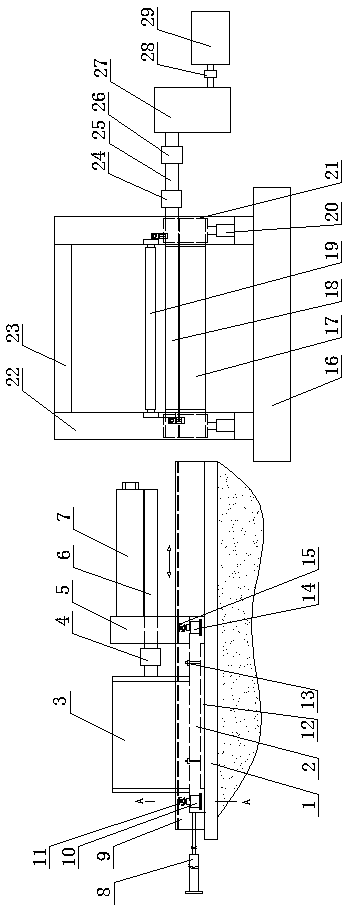

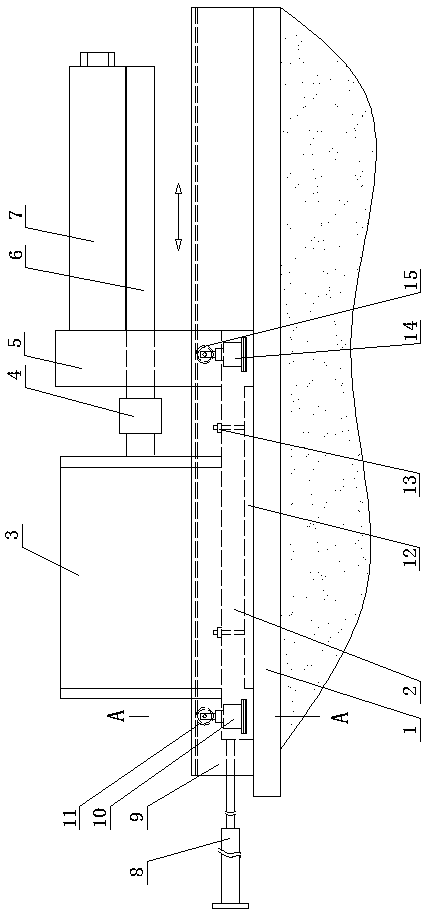

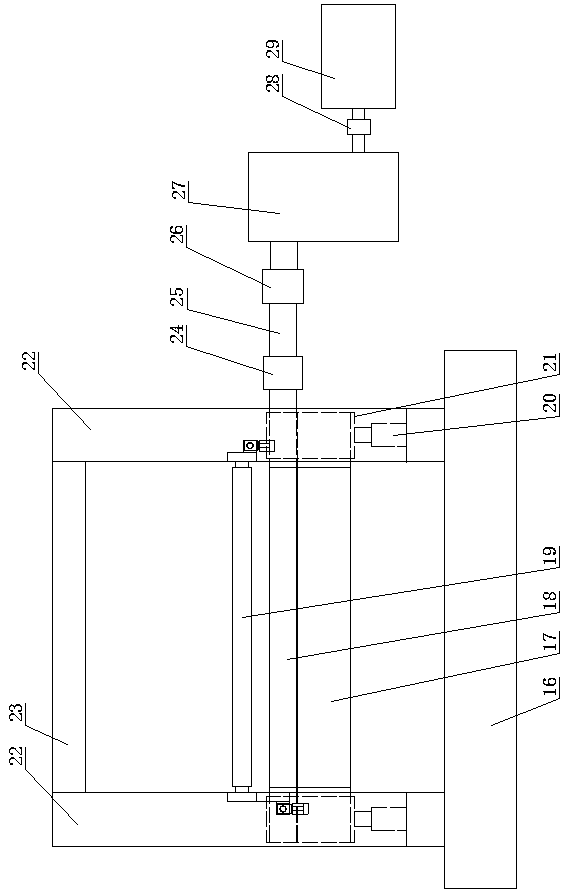

[0042] Such as figure 1 -7. Horizontal four-roll rolling mill, including fixed base guide rail assembly, horizontally movable inner roll assembly, roll stand, workpiece support roller assembly and outer roll assembly.

[0043] The fixed base rail assembly includes a horizontally arranged fixed base 1 and two sets of guide rails 9, the fixed base 1 is fixed on the equipment foundation, and the two sets of guide rails 9 are respectively fixedly connected to both sides of the fixed base 1 in the longitudinal direction, inside each set of guide rails 9 The surfaces are respectively provided with inverted V-shaped positioning grooves 30 .

[0044] The horizontally movable inner roller assembly includes a movable base 2, a horizontally movable oil cylinder 8, an inner roller motor 3, a fixed bracket 5, an inner roller 6 and an inner support roller 7. The mobile base 2 is arranged on the fixed base 1 and is located between two groups of guide rails 9. The horizontally movable oil cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com