Wine product production line control system

A production line and control system technology, applied in bottle filling, bottling machines, liquid bottling, etc., can solve the problems of low degree of automation and inability to meet production needs, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A fertilizer applicator, such as figure 1 Shown, in order to solve above-mentioned technical problem, the present invention is solved by following technical scheme:

[0015] In order to solve the above problems, the present invention provides a wine bottle cleaning and filling system integrating detection, transmission, scrubbing, disinfection, filling, and bottle drying. The present invention is solved by the following technical solutions:

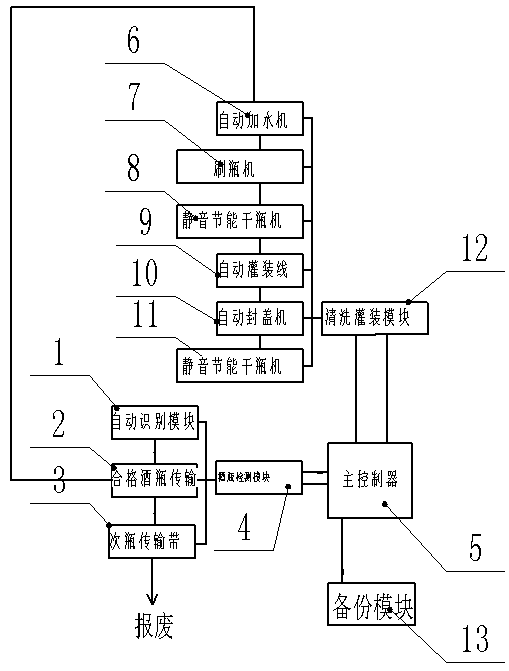

[0016] A wine production line control system, including a wine production line control system, including a main controller, characterized in that the main controller is connected with a wine bottle detection module, a cleaning and filling module, a backup module, the wine The bottle detection module is equipped with an automatic identification module, a qualified wine bottle conveyor belt and a defective bottle conveyor belt. The cleaning and filling module includes an automatic water adding machine, a bottle brushing machine, a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com