Sewage precipitation pool of swinging rod dispersion precipitating agent

A settling tank and precipitant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation separation, water/sewage treatment, etc., can solve the problems of uneven addition of precipitant, uneven precipitation of sewage, complicated removal of sediment, etc., to achieve Good dirt cleaning effect, thorough precipitation, good precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

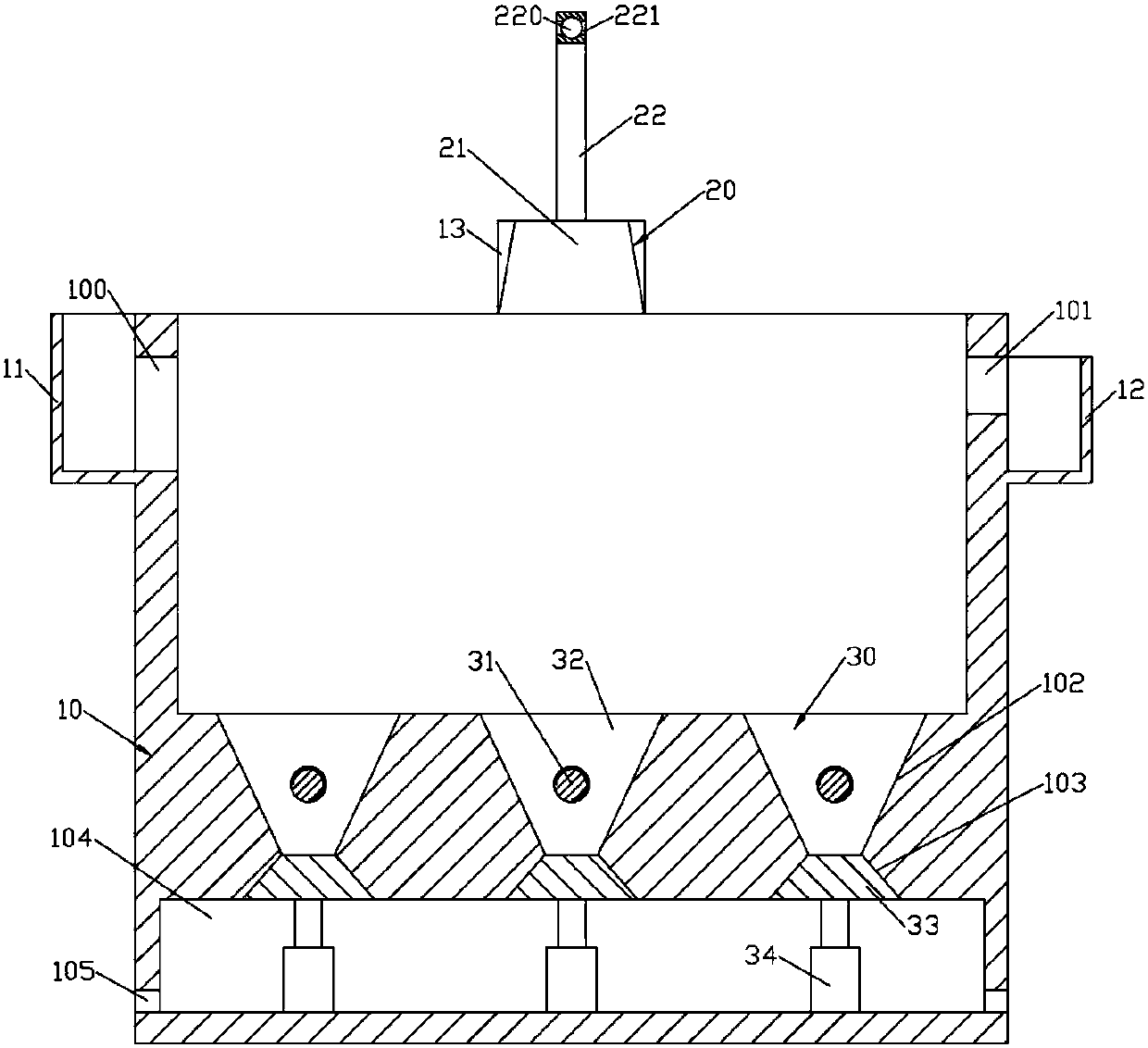

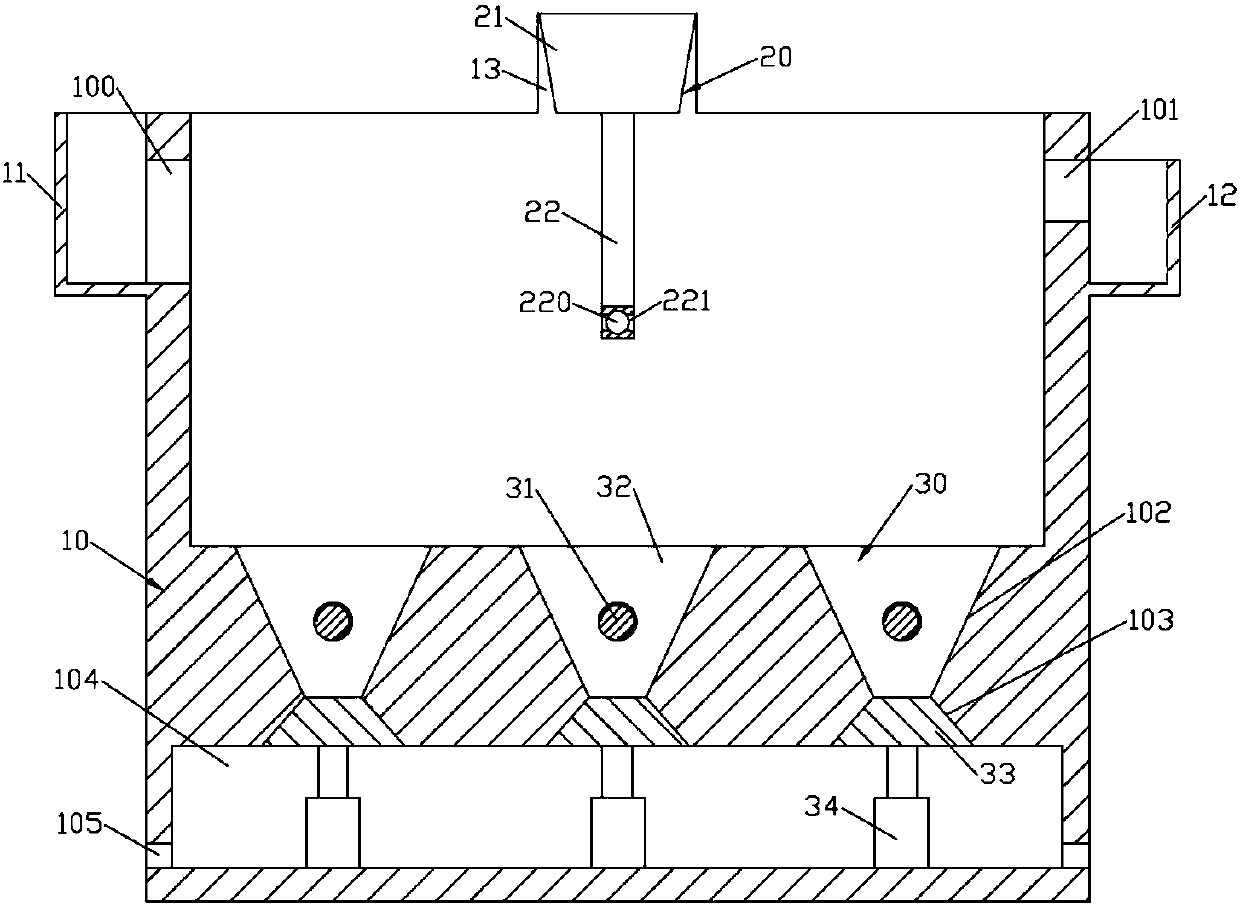

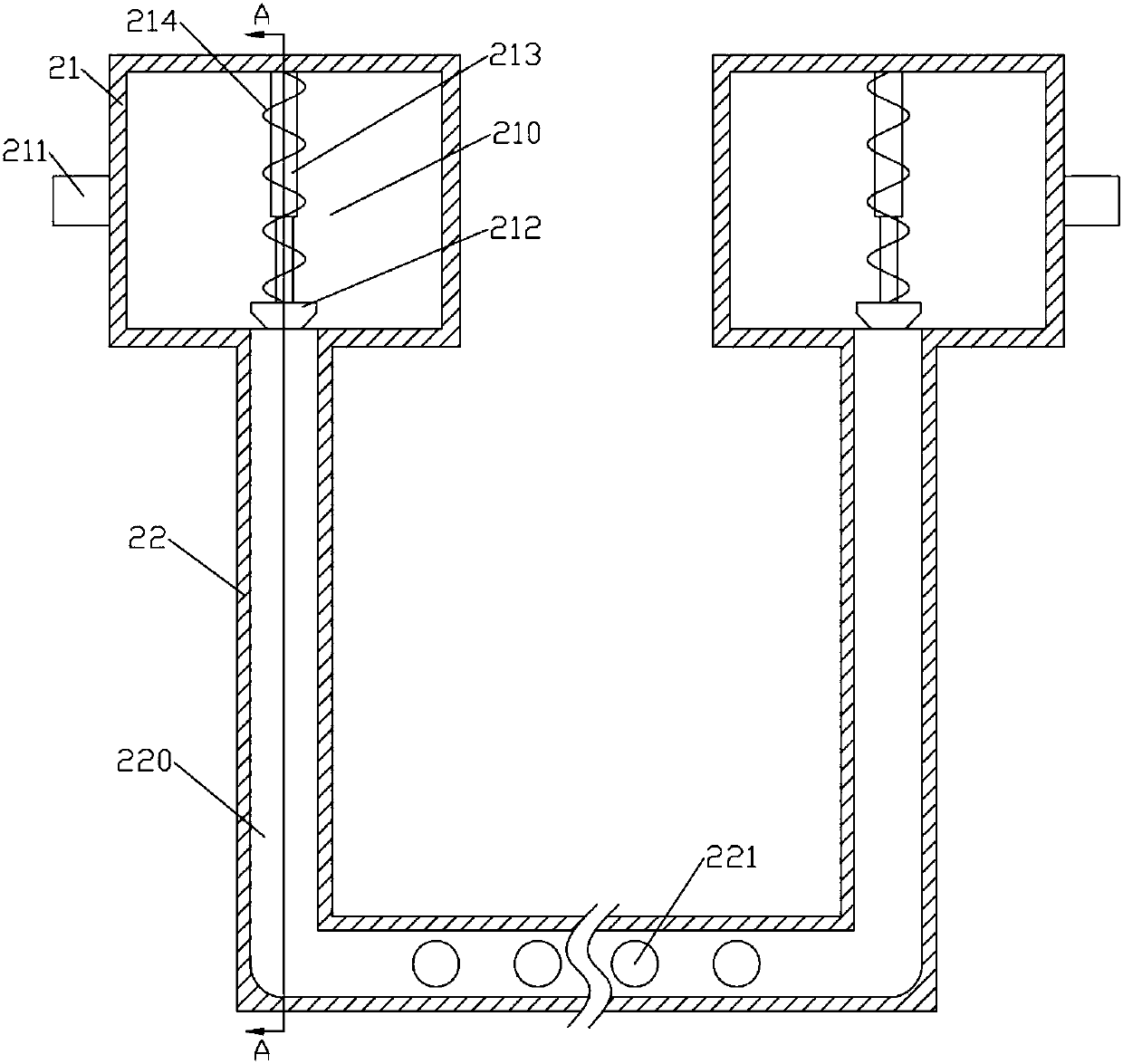

[0016] Such as figure 1 , figure 2 As shown, a sewage sedimentation tank with a swing rod for dispersing precipitant includes a rectangular sewage sedimentation tank 10, a swing rod dispersion device 20 and a dirt cleaning device 30; a water inlet trough 11 is formed on the upper left end of the sewage sedimentation tank 10; 11 A water inlet 100 is formed on the left side wall of the sewage sedimentation tank 10 directly opposite;

[0017] An overflow tank 12 is formed on the upper right end of the sewage sedimentation tank 10; an overflow port 101 is formed on the right side of the sewage sedimentation tank 10 opposite to the overflow tank 12; the upper end surface of the lower side wall of the sewage sedimentation tank 10 is uniform in the left and right directions A number of concave sludge buckets 102 with an isosceles trapezoid shape with a wide top and a narrow bottom are formed; the lower part of the lower side wall of the sewage sedimentation tank 10 is formed with a rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com