System for removing sodium hydroxide during hexamethylenediamine production, and removal method thereof

A technology of sodium hydroxide and hexamethylene diamine, applied in the field of sodium hydroxide removal system, can solve the problems of affecting the rectification effect, reducing the aperture of the tray, and coking in the rectification tower, so as to improve the removal effect and reduce the Fluctuation, guaranteed removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

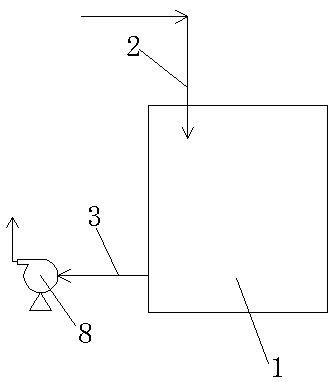

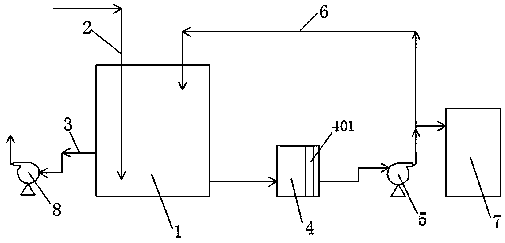

[0026] Embodiment 1: Continuously and slowly send crude hexamethylenediamine into the crude hexamethylenediamine storage tank 1, when the sodium hydroxide liquid level height deposited at the bottom of the crude hexamethylenediamine storage tank 1 is 0.3m, the crude hexamethylenediamine storage tank Tank 1 discharges the liquid of 13 cubic meters to sodium hydroxide separation tank 4, leaves standstill the liquid in sodium hydroxide separation tank 4 for 4min, manually observes the liquid in sodium hydroxide separation tank 4 through glass sight glass 401, until sodium hydroxide After the liquid in the separation tank 4 was obviously stratified, the centrifugal pump A5 was opened to extract the sodium hydroxide and hexamethylenediamine in the sodium hydroxide separation tank 4 respectively, and the removal of the sodium hydroxide was completed.

Embodiment 2

[0027] Embodiment 2: Continuously and slowly send crude hexamethylenediamine into the crude hexamethylenediamine storage tank 1, when the sodium hydroxide liquid level height deposited at the bottom of the crude hexamethylenediamine storage tank 1 is 0.5m, the crude hexamethylenediamine storage tank Tank 1 discharges the liquid of 16 cubic meters to the sodium hydroxide separation tank 4, the liquid in the sodium hydroxide separation tank 4 is allowed to stand for 6 minutes, and the liquid in the sodium hydroxide separation tank 4 is manually observed through the glass sight glass 401 until the sodium hydroxide After the liquid in the separation tank 4 was obviously stratified, the centrifugal pump A5 was opened to extract the sodium hydroxide and hexamethylenediamine in the sodium hydroxide separation tank 4 respectively, and the removal of the sodium hydroxide was completed.

Embodiment 3

[0028] Embodiment 3: Continuously and slowly send crude hexamethylenediamine into the crude hexamethylenediamine storage tank 1, when the sodium hydroxide liquid level height deposited at the bottom of the crude hexamethylenediamine storage tank 1 is 0.4m, the crude hexamethylenediamine storage tank Tank 1 discharges the liquid of 15 cubic meters to the sodium hydroxide separation tank 4, the liquid in the sodium hydroxide separation tank 4 is allowed to stand for 5 minutes, and the liquid in the sodium hydroxide separation tank 4 is manually observed through the glass sight glass 401 until the sodium hydroxide After the liquid in the separation tank 4 was obviously stratified, the centrifugal pump A5 was opened to extract the sodium hydroxide and hexamethylenediamine in the sodium hydroxide separation tank 4 respectively, and the removal of the sodium hydroxide was completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com