Pipeline inner positioning device based on pipeline section length and pipeline connector detection and positioning method thereof

A technology for connectors and pipeline segments, which is applied in the positioning device and positioning field in pipelines, can solve the problems of inapplicability, high cost, and many magnetic marks, and achieve the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

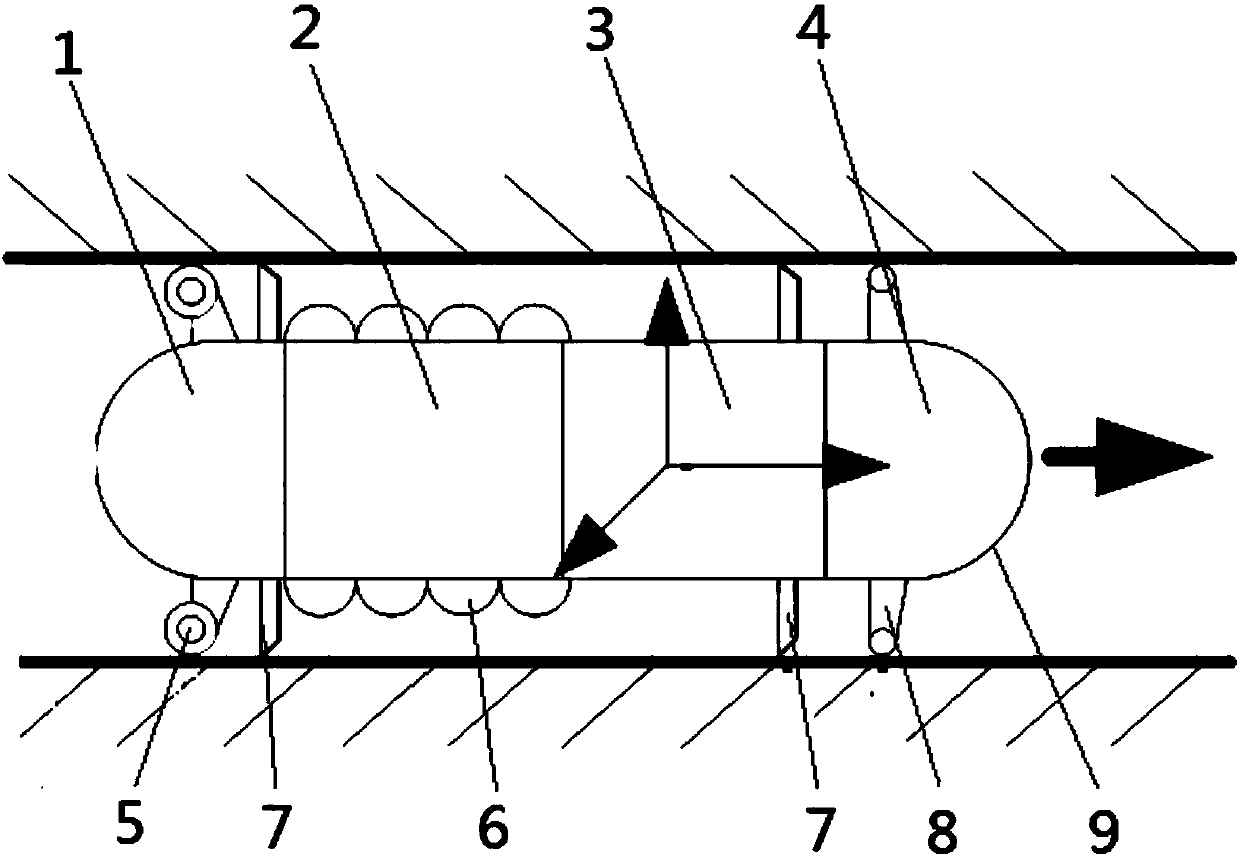

[0035] Specific implementation mode 1: as figure 1 As shown, a positioning device in a pipeline based on pipeline section length and pipeline connector detection according to the present invention includes a data storage unit 1, a data processing unit 2, a MEMS strapdown inertial measurement unit 3, a power supply module 4, and a mileage wheel 5 , pipeline defect detection sensor 6, plastic sealing ring 7, support wheel 8 and main body 9;

[0036] The main body 9 is composed of a sealed cavity, and a data storage unit 1, a data processing unit 2, a MEMS strapdown inertial measurement unit 3, and a power module 4 are sequentially installed from left to right; the two ends of the outer wall of the main body 9 are respectively symmetrical and equally spaced A plurality of mileage wheels 5 and support wheels 8 are installed, and the pipeline defect detection sensor 6 is installed between the mileage wheel 5 and the support wheel 8 on the outer wall of the main body 9, and the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com