High pressure gas impact-loading safety performance test method for energetic material

A high-pressure gas, safety performance technology, applied in the field of safety testing, can solve the problems of insufficient attention, complicated operation, lack of evaluation methods, etc., and achieve the effects of reliable testing data, good test repeatability, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

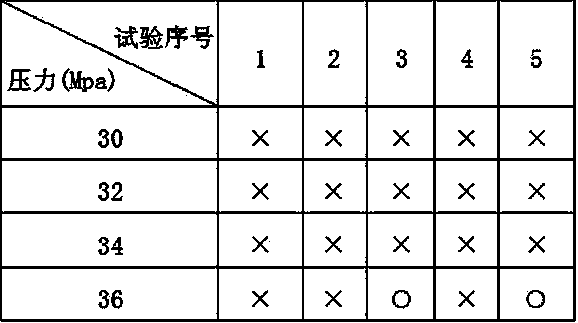

[0016] Example 1: The minimum burst gas pressure value test of Yu-2 liquid fuel.

[0017] Step 1, sample preparation.

[0018] For each test, accurately weigh 100㎎ of the fish-2 liquid fuel test sample (2), add it into a ceramic crucible and put it into the bottom of the sealed sample pool (1), and the low-temperature gas generating agent used in the test is stored in a water bath oven at 40°C before use. Dry for 4h.

[0019] Step two, condition selection.

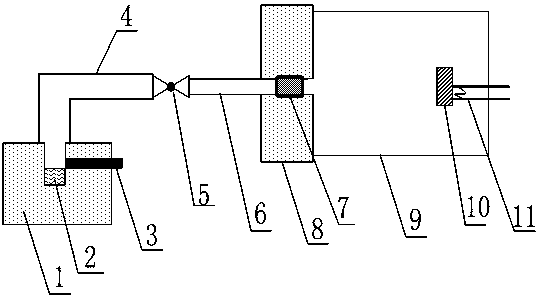

[0020] In the condition selection process, the equipment conditions are: high-pressure gas generating device, high-pressure gas release device and gas pressure detection device. The high-pressure gas generating device uses a low-temperature gas generating agent⑽, which is a non-azide gas generating agent that can generate a large amount of gas when it is excited by the ignition electrode⑾ and burns rapidly in a closed combustion chamber⑼. Its chemical reaction is rapid and the effective gas production capacity Large, le...

Embodiment 2

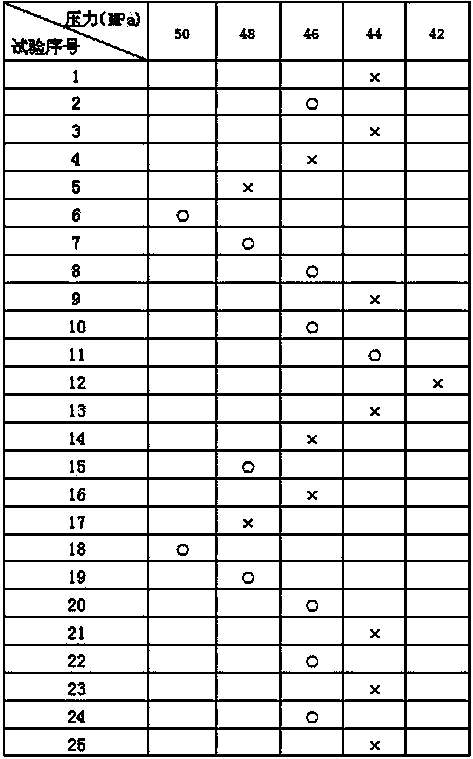

[0029] Example 2: Gas pressure value test of 50% explosion probability of HTPE-103 polyether composite solid propellant.

[0030] Step 1, sample preparation.

[0031] HTPE-103 polyether composite solid propellant is made into φ10mm×3mm tablets for test sample ⑵, and each test is to place a piece of test sample ⑵ horizontally on the bottom of the sealed sample pool ⑴, and the low-temperature gas generating agent used in the test is Dry in a water-bath oven at 40°C for 4 hours before use.

[0032] Step two, condition selection.

[0033] In the condition selection process, the equipment conditions are: high-pressure gas generating device, high-pressure gas release device and gas pressure detection device. The high-pressure gas generating device uses a low-temperature gas generating agent⑽, which is a non-azide gas generating agent that can generate a large amount of gas when it is excited by the ignition electrode⑾ and burns rapidly in a closed combustion chamber⑼. Its chemical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com