Soft magnetic metal dust core and reactor having thereof

A powder magnetic core, soft magnetic technology, applied in metal processing equipment, magnetic materials, magnetic objects, etc., can solve the problem of not getting DC superposition characteristics, low uniformity of soft magnetic metal powder magnetic core, and insufficient improvement. DC superposition characteristics and other problems, to achieve the effect of excellent DC superposition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

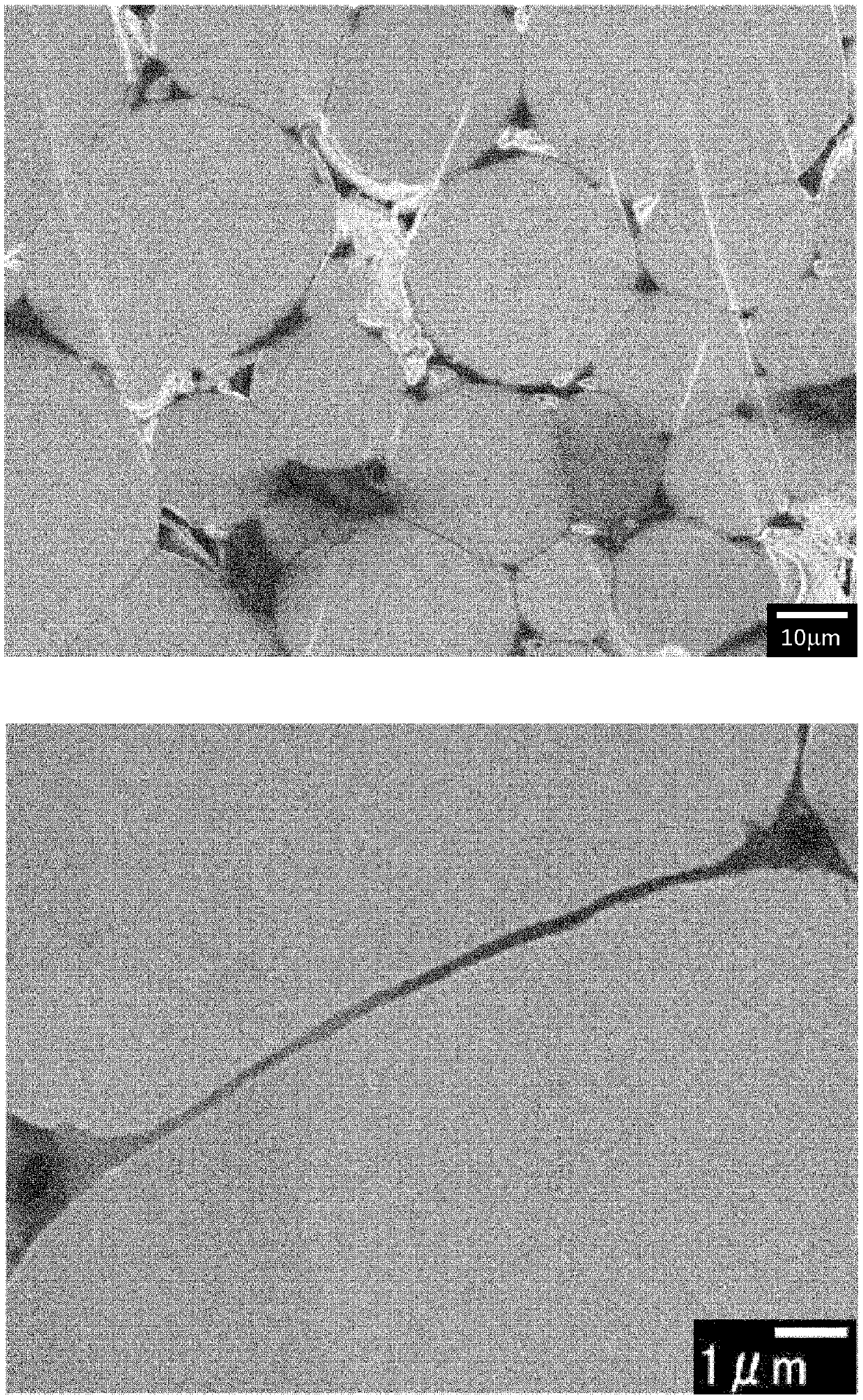

[0066] As the raw material powder, a soft magnetic metal powder composed of Fe-3.0Si, Fe-4.5Si and Fe-6.5Si was produced by a gas atomization method, and a soft magnetic metal powder containing desired Soft magnetic metal powder of B of boron nitride. The soft magnetic metal powder containing B was placed in a tubular furnace, and the soft magnetic metal powder subjected to nitrogen heat treatment in a nitrogen atmosphere was produced at a heat treatment temperature of 1300° C. and a holding time of 30 minutes. The obtained soft magnetic metal powder was dry-classified so that it might become a desired particle diameter, and the powder obtained was prepared. The d50% of the soft magnetic metal powder was measured by a laser diffraction particle size distribution analyzer (HELOS system, manufactured by Sympatec Corporation), and the composition, production method, presence or absence of boron, and d50% of the raw material powder are shown in Table 1.

[0067]

[0068] With ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap