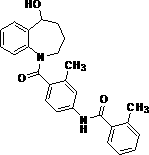

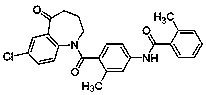

Preparation method of high-purity tolvaptan

A tolvaptan, high-purity technology, applied in the field of drug preparation, can solve the problems of dechlorination impurity residue, inability to completely inhibit dechlorination reaction, and inability to obtain high-purity tolvaptan, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0031] The preparation method of the high-purity tolvaptan of the present embodiment is as follows:

[0032] Add 5g of the compound of formula II into a 100mL three-neck flask, then add 25mL of tetrahydrofuran, stir to dissolve, cool down to -5~0°C, control the temperature at -5~0°C, and dropwise add 1.73g of dihydrofuran with a concentration of 70wt%. Hydrogen bis(2-methoxyethoxy)sodium aluminate toluene solution, heat up to 10-20°C after addition, and stir for 2 hours.

[0033] After the completion of the reaction monitored by HPLC, the temperature was controlled at 10-20°C, and 50mL of water was added dropwise. Solids were precipitated. Stirring was continued for 1-2h, and suction filtration was performed. The filter cake was recrystallized with methanol aqueous solution, and dried under reduced pressure to obtain white crystals of tolvaptan. 4.73g, the yield was 94.2%, the HPLC purity was 99.97%, and the dechlorinated impurity IV was not detected.

Embodiment 2~ Embodiment 6)

[0035] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0036] Table 1

[0037]

Embodiment 7~ Embodiment 10)

[0039] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 2.

[0040] Table 2

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com