Grating measuring device

A grating measurement and grating technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large measurement errors, large size of the light-passing surface of the grating ruler, and high cost, and achieve convenient installation and use, compressed installation space, and size compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

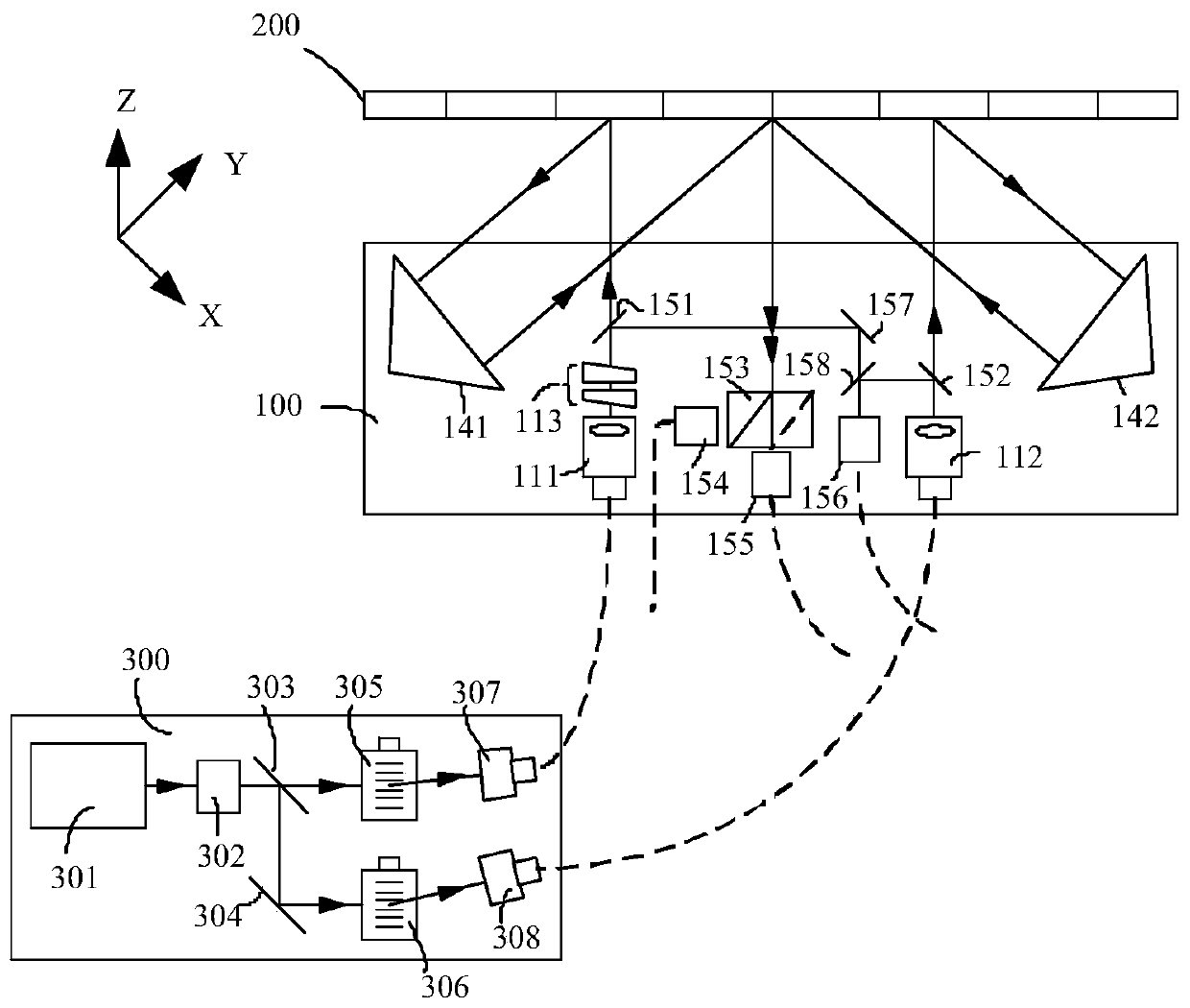

[0059] Such as figure 1 As shown, the grating measuring device of the present embodiment includes:

[0060] A light source module 300, configured to generate two beams of light with different frequencies;

[0061] Grating 200;

[0062] Multiple detectors (not shown in the figure),

[0063] Signal processor (not shown in the figure);

[0064] as well as

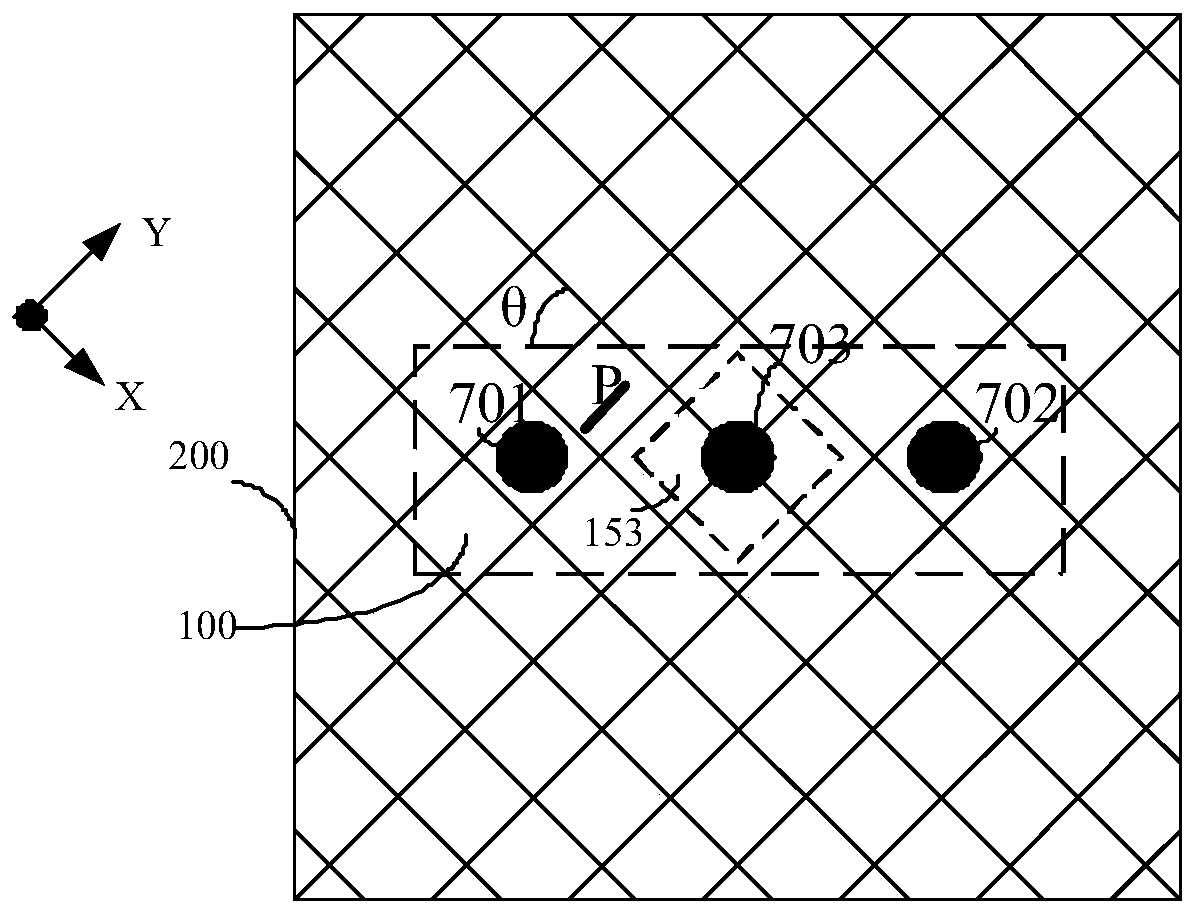

[0065] The grating measurement probe 100 includes a dual-frequency incident light module, a horizontal detection module, a reference detection module and two retroreflectors arranged symmetrically. In this embodiment, the retroreflectors are preferably corner cube prisms 141, 142, wherein , the dual-frequency incident light module is used to receive the two beams and project the two beams onto the surface of the grating 200 and the reference detection module, the two beams are diffracted on the surface of the grating 200, and the diffracted light is projected onto the surface of the grating 200 The corresponding retrorefl...

Embodiment 2

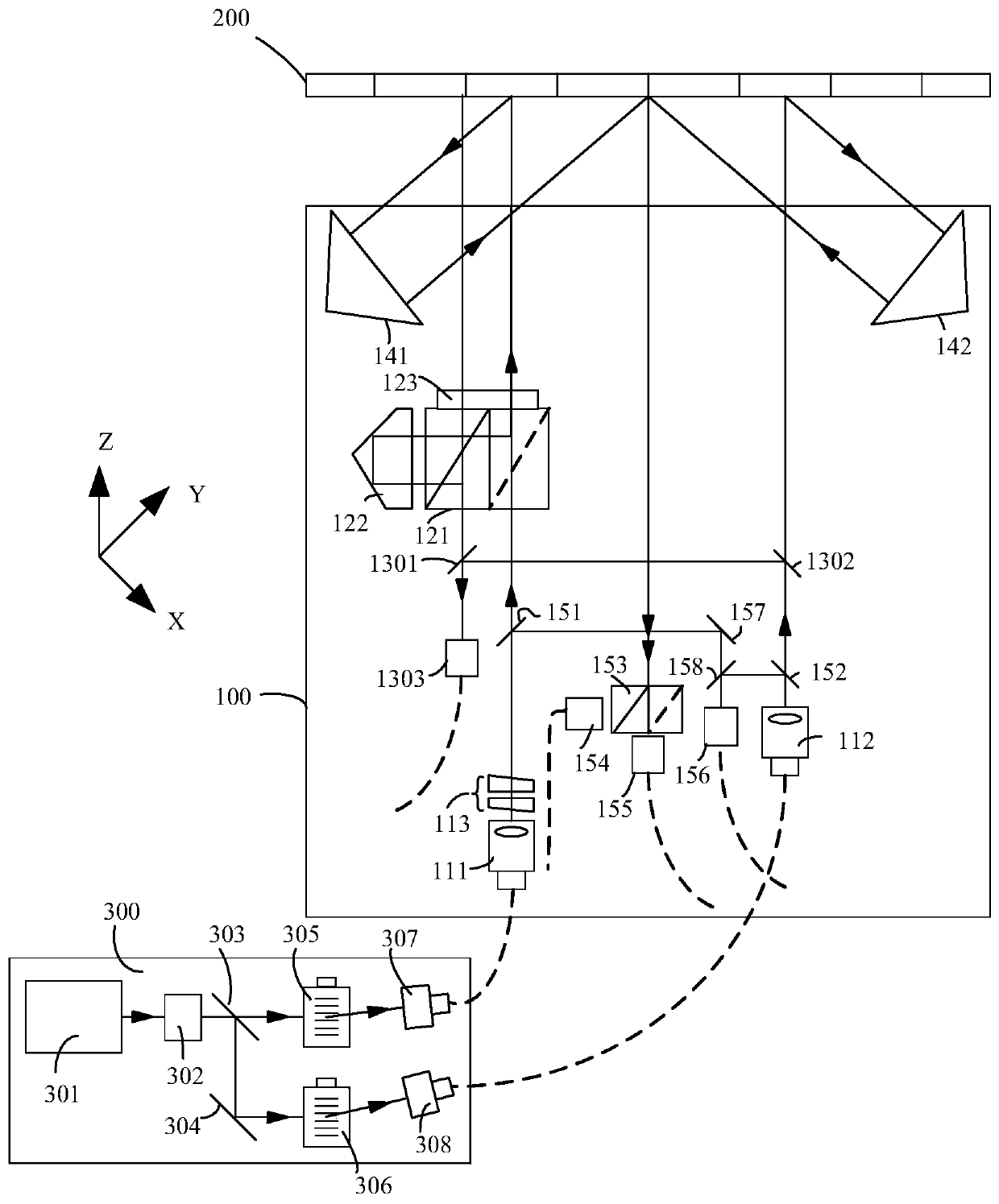

[0101] The difference between this embodiment and Embodiment 1 is that this embodiment can realize vertical and horizontal displacement measurement at the same time.

[0102] Such as image 3 As shown, compared with Embodiment 1, this embodiment adds: a vertical measurement module arranged on the optical path between the dual-frequency incident light module and the grating 200, and a vertical detection module corresponding to the vertical measurement module .

[0103] Continue to refer to image 3 , the vertical measurement module includes: a second polarization beam splitter prism 121, a second corner cube prism 122, and a polarization controller 123. The measurement beam emitted by the dual-frequency incident light module is first transmitted through the second polarization beam splitter prism 121, and is controlled by polarization. The polarizer 123 rotates the polarization direction and projects onto the grating 200 to diffract. The -1 order diffracted light in the diffr...

Embodiment 3

[0111]The difference between this embodiment and Embodiment 2 is that the vertical detection module in this embodiment does not include the fourth beam splitter 1301, and the measurement beam with vertical displacement information returned by the grating is combined with the fifth beam splitter in other ways. The reference beams split by the beam mirror 1302 are combined to form an interference signal a1 to realize vertical measurement. Such as Figure 5 As shown (the part used for horizontal measurement is not shown in the figure), the reference beam is reflected by the fifth beam splitter 1302, enters the second polarization beam splitter 121, and is merged with the measuring beam with the vertical position signal and then is The fourth remote coupler 1303 couples the output.

[0112] The scheme for combining light beams shown in this device can be implemented in a variety of ways. It can be implemented in embodiment 2 through the fourth beam splitter 1301 to combine light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com