Method for preparing hydrolyzed shell nacre powder

A nacre and shell technology, which is applied in skin care preparations, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems of large nacre powder particles, low active ingredients, and unfavorable skin absorption. The effect of skin absorption, small damage, and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

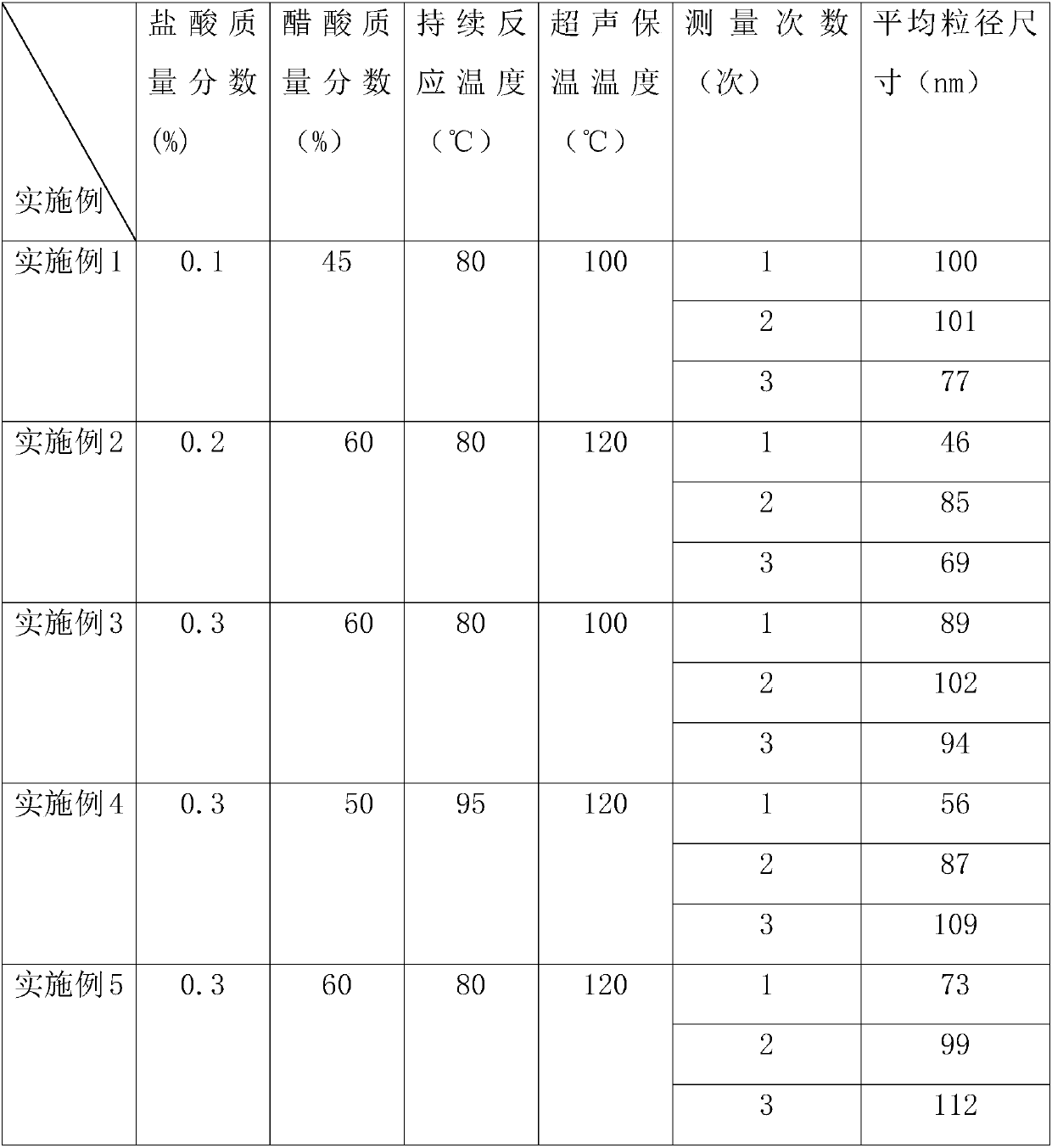

Embodiment 1

[0017] A kind of preparation method of hydrolyzed conch nacre powder in the present embodiment, comprises the following steps:

[0018] 1) Pretreatment: Soak the shells in hydrochloric acid with a mass fraction of 0.1% for 24 hours, wash them with distilled water three times after soaking, remove impurities on the shells, and dry them at 68°C for 12 hours to obtain washed and dried shell spare;

[0019] 2) Preparation of hydrolyzate: Soak the washed and dried shells with 45% acetic acid for 24 hours, and keep the reaction temperature at 80°C until there is no CO 2 Gas is generated, and the solution obtained from the reaction is ultrasonically incubated at 100°C for 24 hours. After the reaction is stopped, the hydrolyzed solution is obtained after filtering to remove impurities;

[0020] 3) Preparation of nacre powder: spray-dry the hydrolyzed solution at 210MPa to obtain a powder which is passed through a high-pressure homogenizer and passed through a 1000-mesh sieve to obtai...

Embodiment 2

[0022] A kind of preparation method of hydrolyzed conch nacre powder in the present embodiment, comprises the following steps:

[0023] 1) Pretreatment: soak the shells with hydrochloric acid with a mass fraction of 0.2% for 24 hours, wash them with distilled water three times after soaking, remove impurities on the shells, and dry them at a temperature of 70°C for 12 hours to obtain washed and dried shells. shell spare;

[0024] 2) Preparation of hydrolyzate: soak the washed and dried shells with 60% acetic acid for 20 hours, and continue the reaction at 80°C until no CO 2 Gas is generated, and the solution obtained from the reaction is ultrasonically incubated at 120°C for 24 hours. After the reaction is stopped, the hydrolyzed solution is obtained after filtering and removing impurities;

[0025] 3) Preparation of nacre powder: spray-dry the hydrolyzed solution at 210MPa to obtain a powder which is passed through a high-pressure homogenizer and passed through a 1000-mesh s...

Embodiment 3

[0027] A kind of preparation method of hydrolyzed conch nacre powder in the present embodiment, comprises the following steps:

[0028] 1) Pretreatment: soak the shells with hydrochloric acid with a mass fraction of 0.3% for 24 hours, wash them with distilled water three times after soaking, remove impurities on the shells, and dry them at a temperature of 80°C for 12 hours to obtain washed and dried shells. shell spare;

[0029] 2) Preparation of hydrolyzate: soak the washed and dried shells with 60% acetic acid for 20 hours, and continue the reaction at 80°C until no CO 2 Gas is generated, and the solution obtained from the reaction is ultrasonically incubated at 100°C for 24 hours. After the reaction is stopped, the hydrolyzed solution is obtained after filtering to remove impurities;

[0030] 3) Preparation of nacre powder: spray-dry the hydrolyzed solution at 210MPa to obtain a powder which is passed through a high-pressure homogenizer and passed through a 1000-mesh siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap