Automatic sand adding station

A sand adding station and sand rack technology, applied in the field of sand adding monitoring and adjustment system, can solve the problems of increasing defective products, low work efficiency, large workload, etc., and achieve the effects of convenient procedure operation, reduction of defective products, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

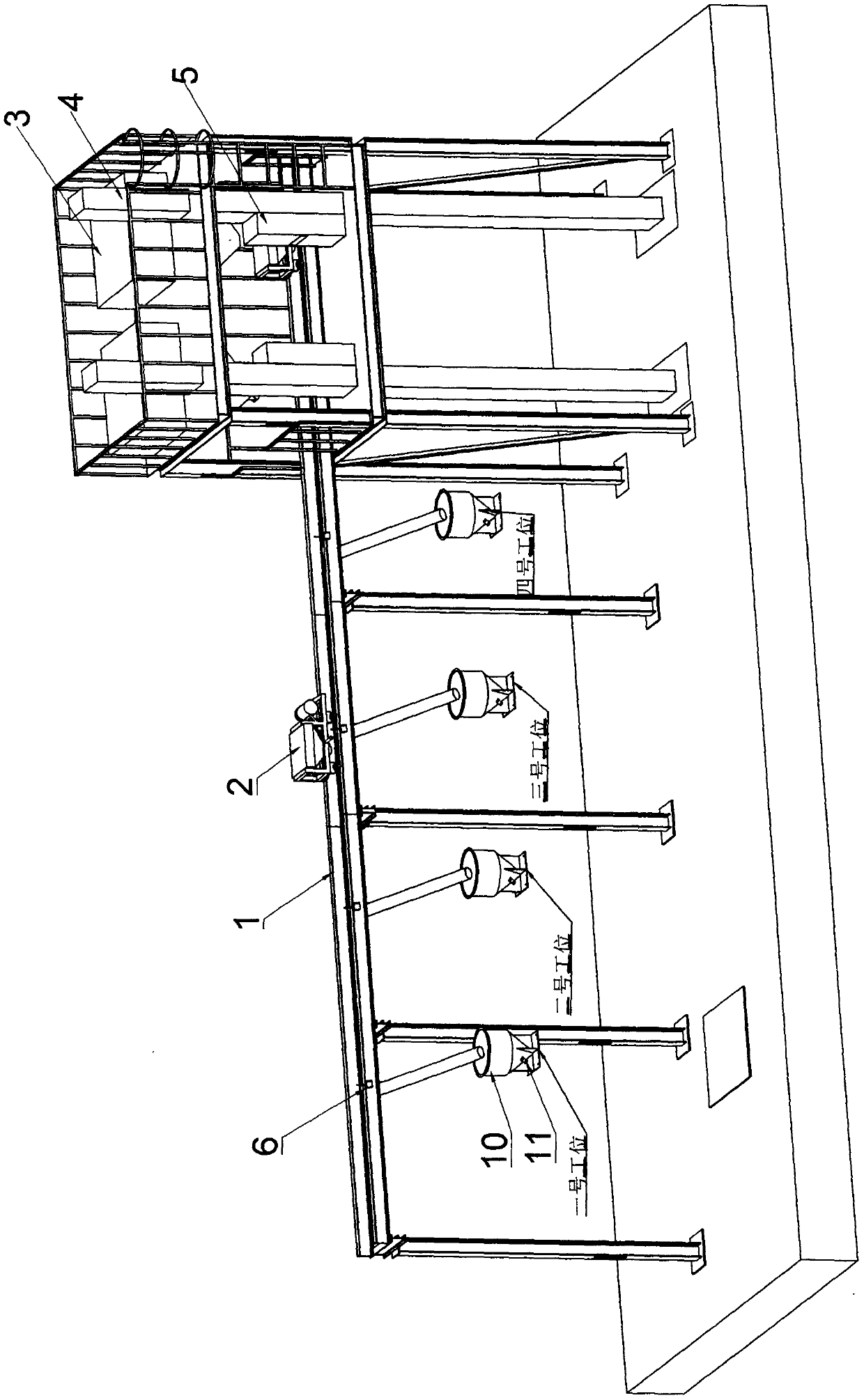

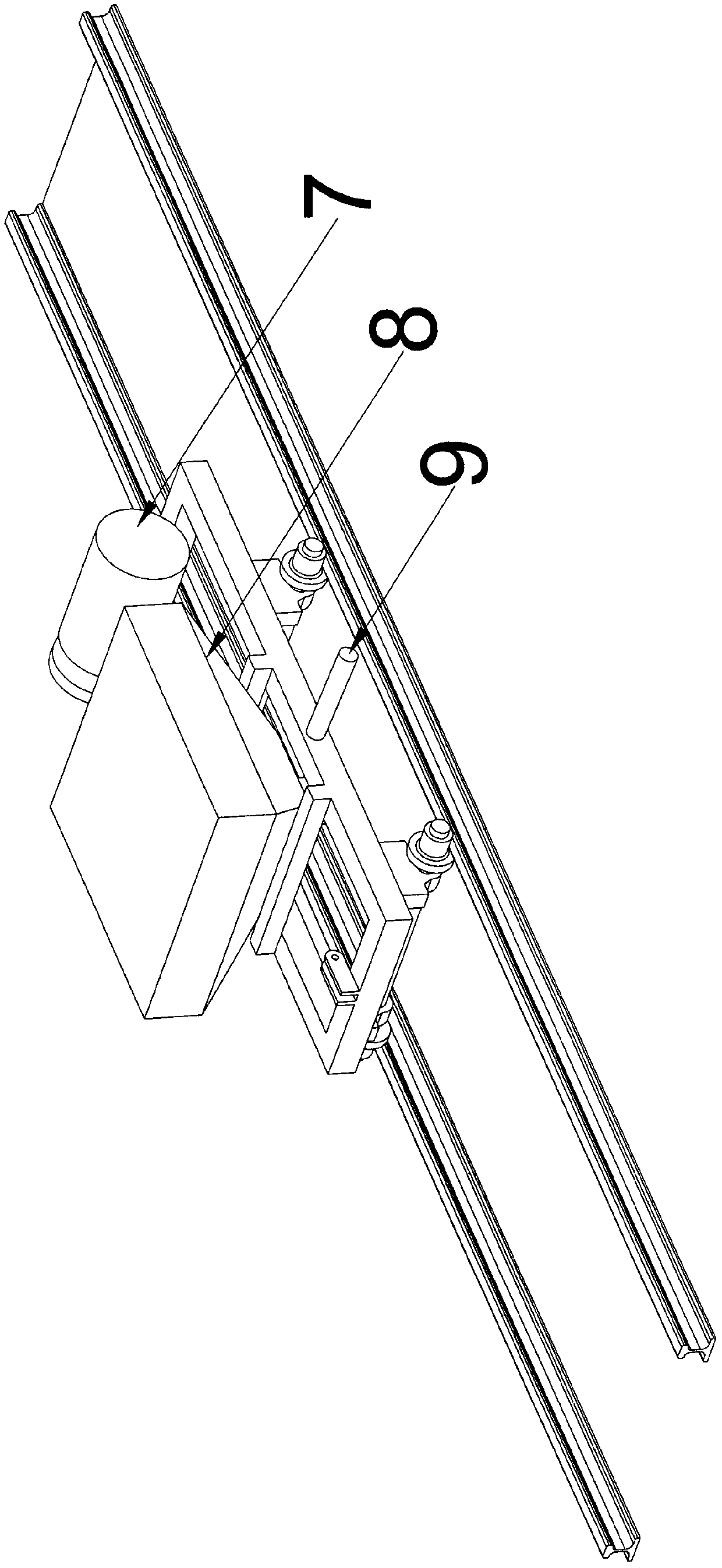

[0010] refer to figure 1 , figure 2 It can be seen that the present invention discloses an automatic sand adding station of a sand adding monitoring and adjusting system, including a sand adding frame 1, a sand adding vehicle 2, and a hopper 10, which are installed on the sand adding frame 1 and above the hopper 10. Some travel switches 6 (as shown in the figure are four travel switches, corresponding to four stations, and four hoppers), the material level switch 11 is installed on the hopper 10, the switch touch lever 9 is installed on the sand adding car 2, and the adding The sand frame 1 is equipped with a microcomputer control mechanism 5; the sand adding vehicle motor 7, travel switch 6, and material level switch 11 of the described sand adding vehicle 2 are respectively connected with the microcomputer control mechanism 5 (including frequency converter, touch screen, etc.).

[0011] Wherein, the sand adding vehicle 2 is installed on the described sand adding frame 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com