Method for preparing two-dimensional nano-material by using silk fibroin stripping

A technology of two-dimensional nanomaterials and silk fibroin, which is applied in the field of nanomaterial preparation and biomedical application, can solve the time-consuming problems of two-dimensional nanomaterials, and achieve rapid and simple peeling preparation process, good dispersibility, and good biocompatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

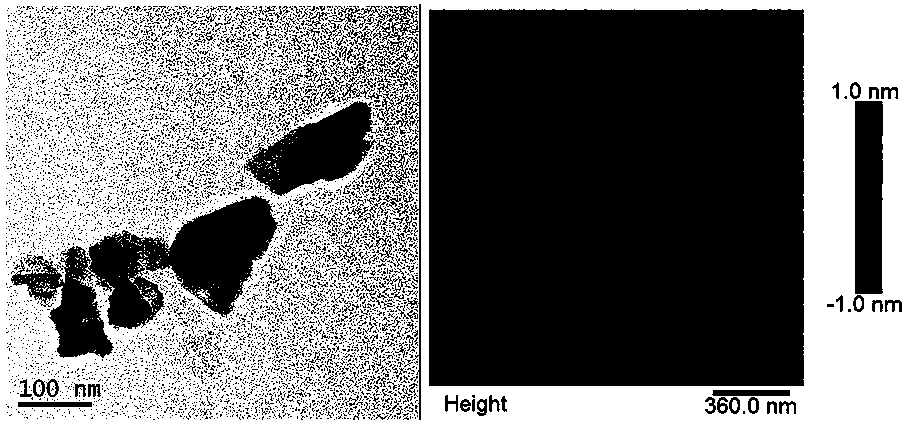

[0016] Fabrication of graphene nanomaterials using silk fibroin exfoliation

[0017] The silk fibroin is degummed, dissolved, dialyzed and filtered to prepare a silk fibroin aqueous solution with a mass concentration of 5%. The silk fibroin aqueous solution is reacted with a diazonium salt to modify the tyrosine residue of the silk fibroin by carboxylation. It is then reacted with chloroacetic acid to carboxylate serine residues. After dialysis, a carboxylated silk fibroin solution with a mass concentration of 2% was prepared. Disperse 45g of graphite powder into 10ml of carboxylated silk fibroin solution, and then ultrasonicate for 2 hours at an ultrasonic power of 300W, then move the aqueous solution into a microtube and wash it by centrifugation to obtain a single layer of graphite dispersed in the aqueous solution ene two-dimensional nanomaterials. At the same time, the graphene two-dimensional nanomaterials were co-incubated with the cells, and after 24 hours of co-cult...

Embodiment 2

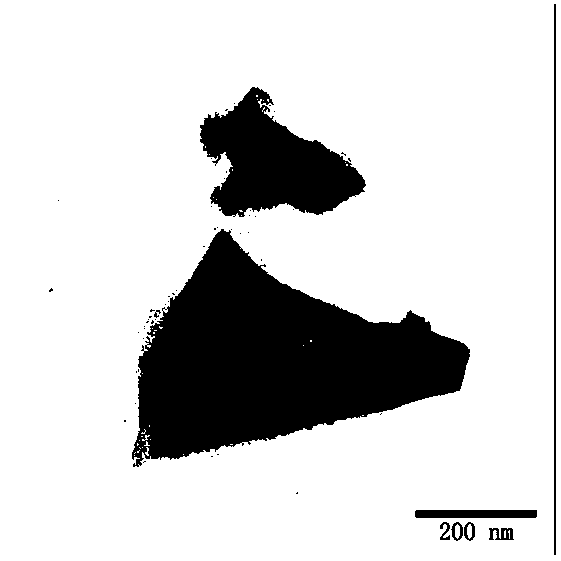

[0019] Fabrication of black phosphorus nanomaterials using silk fibroin exfoliation

[0020] The silk fibroin is degummed, dissolved, dialyzed and filtered to prepare a silk fibroin aqueous solution with a mass concentration of 16%. The silk fibroin aqueous solution is reacted with a diazonium salt to modify the tyrosine residue of the silk fibroin by carboxylation. It is then reacted with chloroacetic acid to carboxylate serine residues. After dialysis, a carboxylated silk fibroin solution with a mass concentration of 8% was prepared. Disperse 10g of black phosphorus powder into 200ml of carboxylated silk fibroin solution, and then ultrasonicate for 5 hours at an ultrasonic power of 50W. Black phosphorus two-dimensional nanomaterials. At the same time, the black phosphorus two-dimensional nanomaterials were co-incubated with the cells. After 24 hours of co-cultivation with the cells at a high black phosphorus concentration (500 μg / mL), the survival rate of the cells was sti...

Embodiment 3

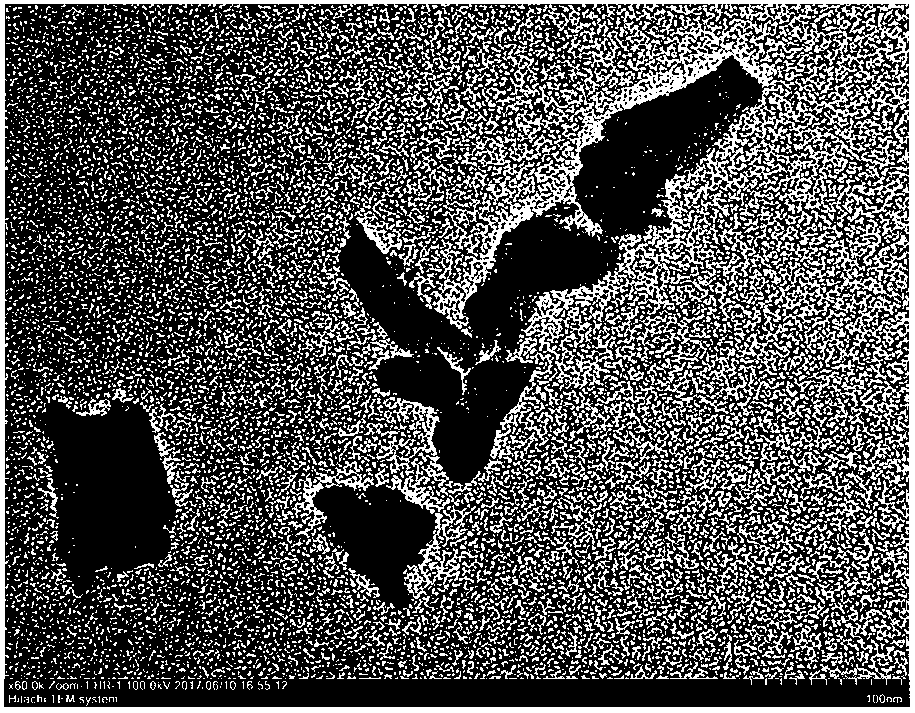

[0022] Fabrication of black phosphorus nanomaterials using silk fibroin exfoliation

[0023] The silk fibroin is degummed, dissolved, dialyzed and filtered to prepare a silk fibroin aqueous solution with a mass concentration of 20%. The silk fibroin aqueous solution is reacted with a diazonium salt to carry out carboxylation modification on the tyrosine residue of the silk fibroin. It is then reacted with chloroacetic acid to carboxylate serine residues. After dialysis, a carboxylated silk fibroin solution with a mass concentration of 15% was prepared. Disperse 80g of black phosphorus powder into 800ml of carboxylated silk fibroin solution, then vibrate for 1 hour at a shaking power of 300W, then move the aqueous solution into a microtube, and wash it by centrifugation to obtain a single layer of silk fibroin dispersed in the aqueous solution. Black phosphorus two-dimensional nanomaterials. At the same time, the black phosphorus two-dimensional nanomaterials were co-incubate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com