Preparation method for permanent magnet ferrite

A technology of permanent magnet ferrite and silicon oxide, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as high temperature and performance deviation of permanent magnet ferrite, and achieve improved magnetic performance and easy predictability. The effect of burning and reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

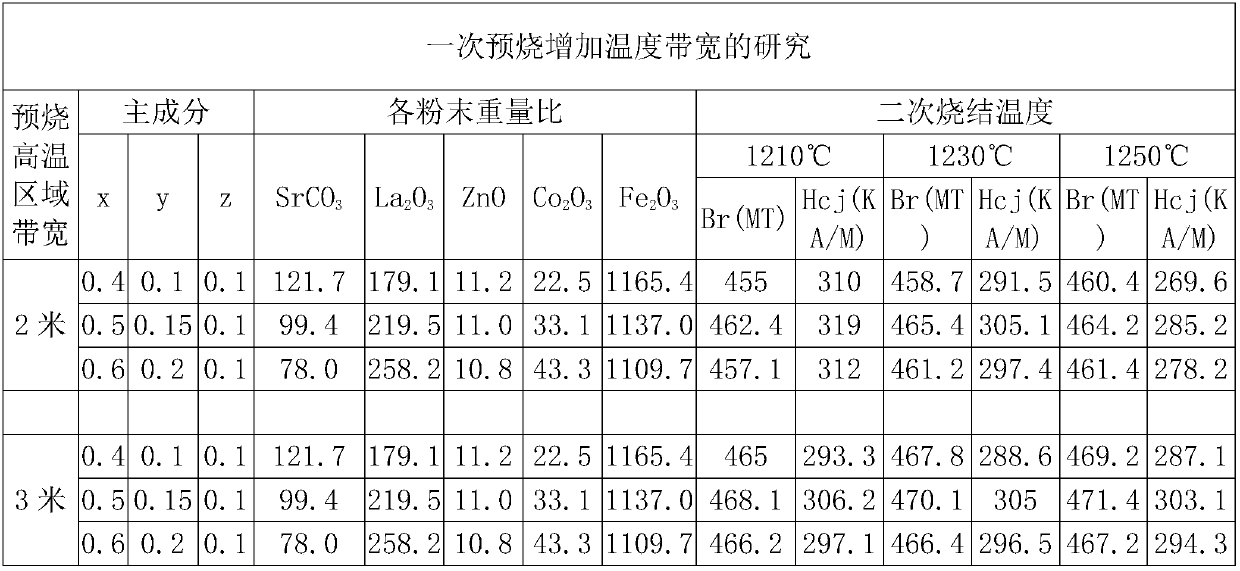

Embodiment 1

[0022] The present embodiment provides a kind of preparation method of permanent magnet ferrite, specifically following steps:

[0023] (1) Ingredients weighing and wet grinding

[0024] This preparation method batching total amount is by 1500kg batching, by molecular formula Sr 1-x La x Fe 2n-y-z co y Zn z o 19 Weigh the main phase raw materials of permanent magnet ferrite according to the molar ratio: x is 0.4, y is 0.1, z is 0.1, n is 5.4, x / (y+z) is 2, and thus the strontium carbonate powder ( Purity ≥ 98wt%, original average particle size of particles 2.0um) 121.7kg, lanthanum oxide powder (purity ≥ 99.9wt%, original average particle size 1.5um) 179.1kg, zinc oxide powder (purity ≥ 98.0wt%, original particle size Average particle size 2.0um) 11.2kg, cobalt oxide powder (purity ≥ 99wt%, the original average particle size of particles 2.0um) 22.5kg; Add a primary additive to the main phase raw material powder, the primary additive is silicon oxide and boric acid, The...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of permanent magnet ferrite, specifically following steps:

[0039] (1) Ingredients processing

[0040] This preparation method batching total amount is by 1500kg batching, by molecular formula Sr 1-x La x Fe 2n-y-z co y Zn z o 19 Weigh the main phase raw materials of permanent magnet ferrite according to the molar ratio: x is 0.5, y is 0.15, z is 0.1, n is 5.4, x / (y+z) is 2, and thus the strontium carbonate powder ( Purity≥98wt%, the original average particle size of particles is 2.0um) 99.4kg, lanthanum oxide powder (purity≥99.9wt%, original average particle size of particles is 1.5um) 219.5kg, zinc oxide powder (purity≥98.0wt%, original particle size Average particle size 2.0um) 11kg, cobalt oxide powder (purity ≥ 99wt%, the original average particle size of particles 2.0um) 33.1kg; Add a primary additive to the main phase raw material powder, the primary additive is silicon oxide and boric acid, add ...

Embodiment 3

[0054] The present embodiment provides a kind of preparation method of permanent magnet ferrite, specifically following steps:

[0055] (1) Ingredients processing

[0056] This preparation method batching total amount is by 1500kg batching, by molecular formula Sr 1-x La x Fe 2n-y-z co y Zn z o 19 Weigh the main phase raw materials of permanent magnet ferrite according to the molar ratio: x is 0.6, y is 0.2, z is 0.1, n is 5.4, x / (y+z) is 2, and thus the strontium carbonate powder ( Purity ≥ 98wt%, the original average particle size of particles is 2.0um) 78kg, lanthanum oxide powder (purity ≥ 99.9wt%, original average particle size 1.5um) 258.2kg, zinc oxide powder (purity ≥ 98.0wt%, original average particle size Particle size 2.0um) 10.8kg, cobalt oxide powder (purity ≥ 99wt%, original average particle size of particles 2.0um) 43.3kg; Add a primary additive to the main phase raw material powder, the primary additive is silicon oxide and boric acid, add Ratio For ever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com