Light rail elevated prefabricated box girder erection construction device and construction method thereof

A construction device, box girder technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

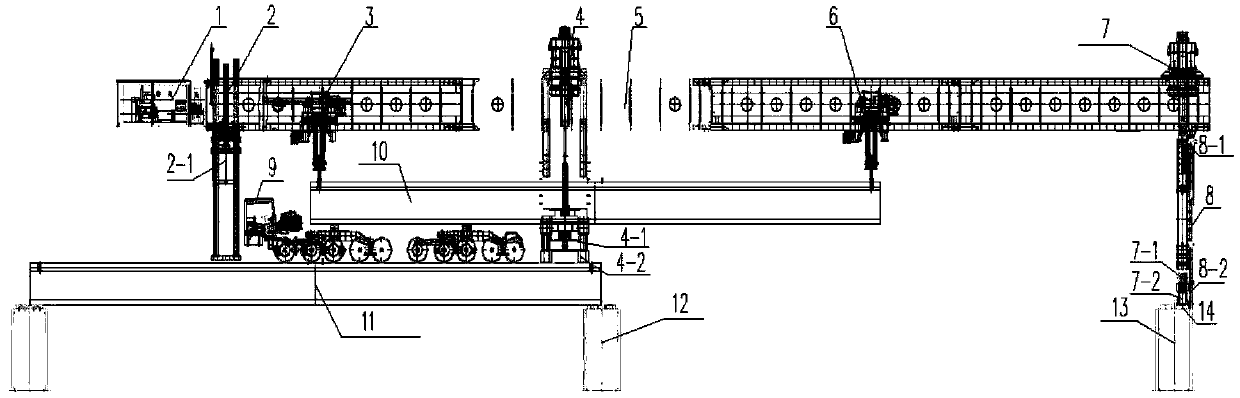

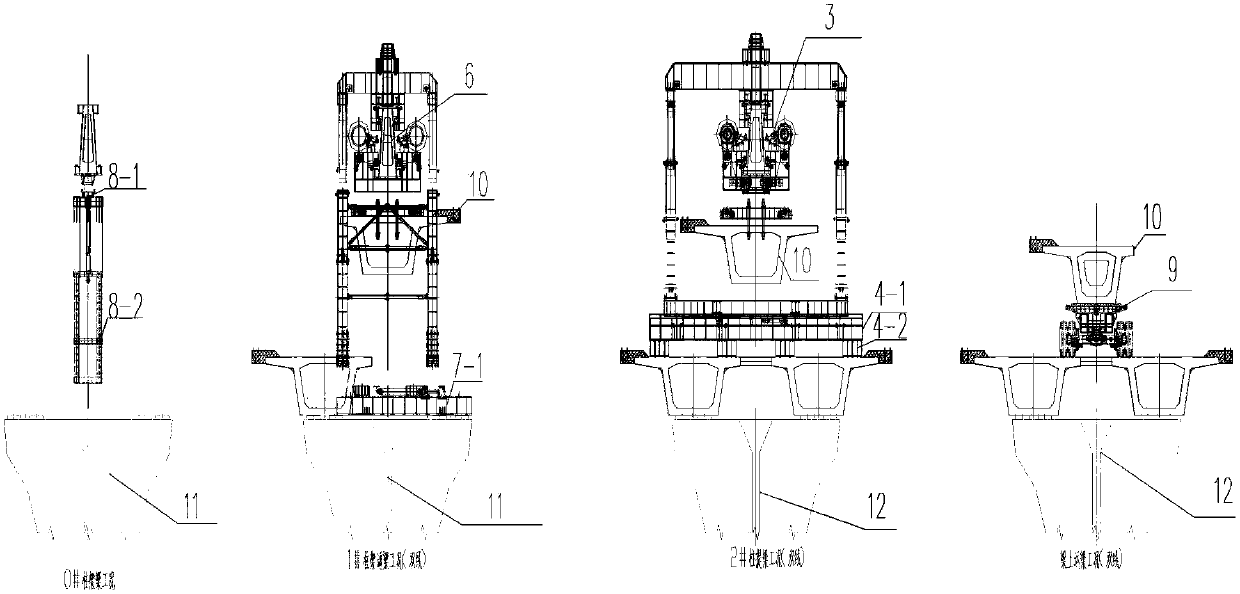

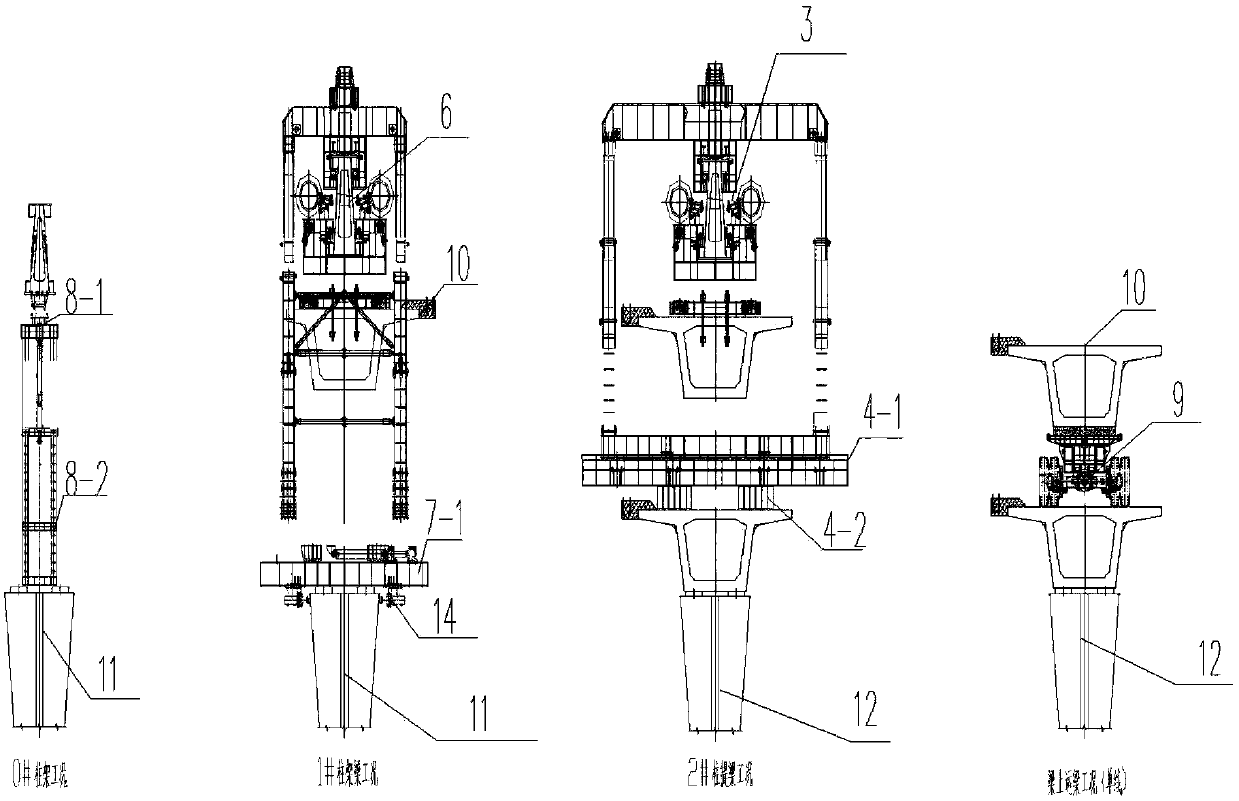

[0033] Embodiment 1: The construction device adopted in the construction method of the present invention is a walking type single guide beam bridge erecting machine, which consists of a tail bracket and an electric power system 1, No. , rear crane beam trolley 3, No. Track shifting 7-1, No. 1 column adjustment section 7-2, No. 0 column 8, addition of rotating seat 8-1 to No. 0 column, and No. 0 column adjustment section 8-2. Measures such as adding a swivel seat to No. 0 column 8, shortening the overall length of the bridge erecting machine, adding a lower lateral movement mechanism to No. 1 and No. 2 columns, and setting jack feet at the bottom of No. 1 column 7 close to both sides of the single pier, etc. Ensure the smooth erection of precast beams.

[0034] The following is combined with the erection of the prefabricated beams of the light rail elevated in the elevated section from the East Airport Station to Zhetang Station and the section of the entrance and exit section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com