Seismic joints of steel structures for prefabricated buildings and their construction methods

An architectural and prefabricated technology, applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems of poor plastic deformation ability of welds, deformation at nodes, and fractures at nodes, etc. Improved construction efficiency and outstanding seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

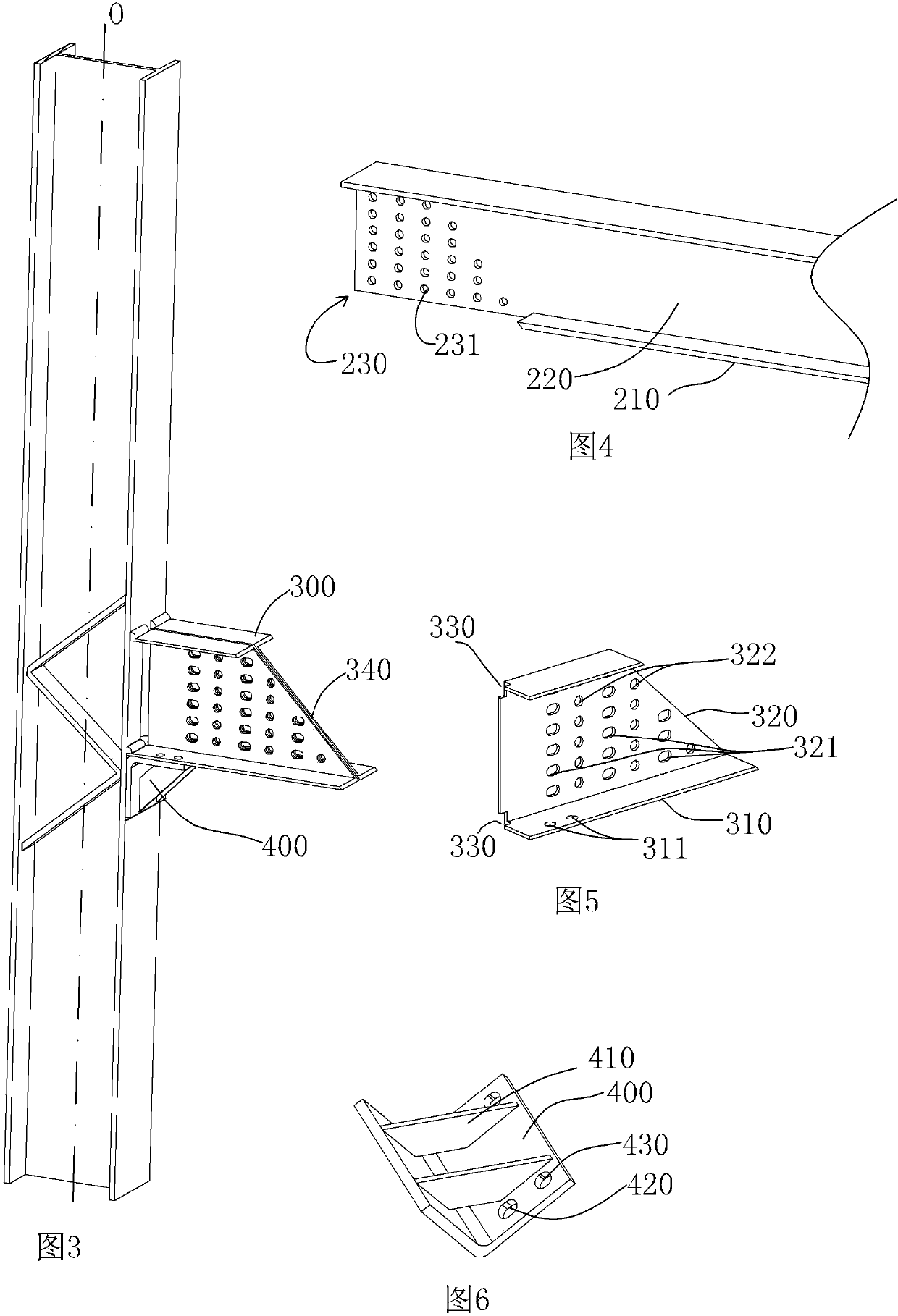

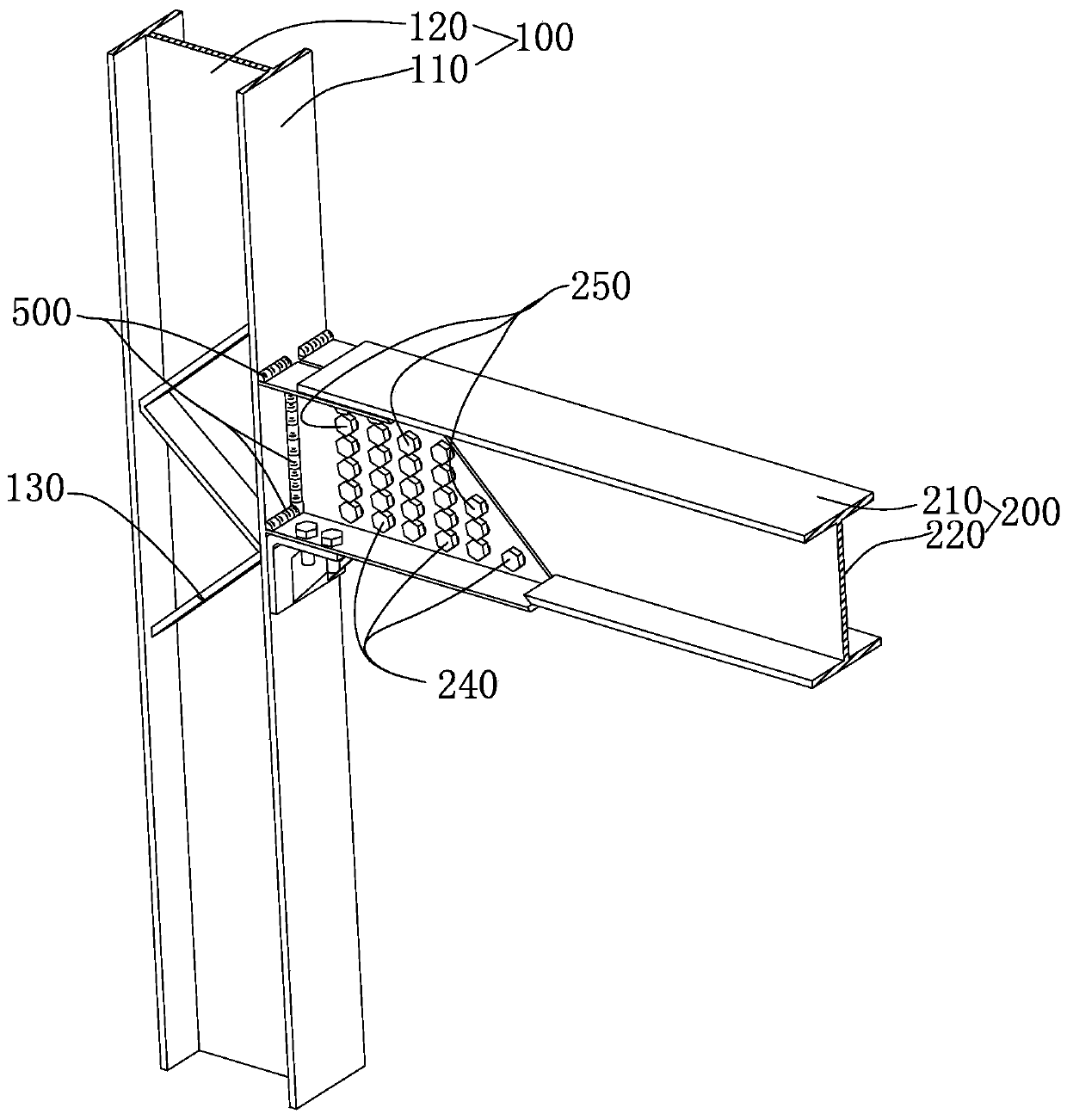

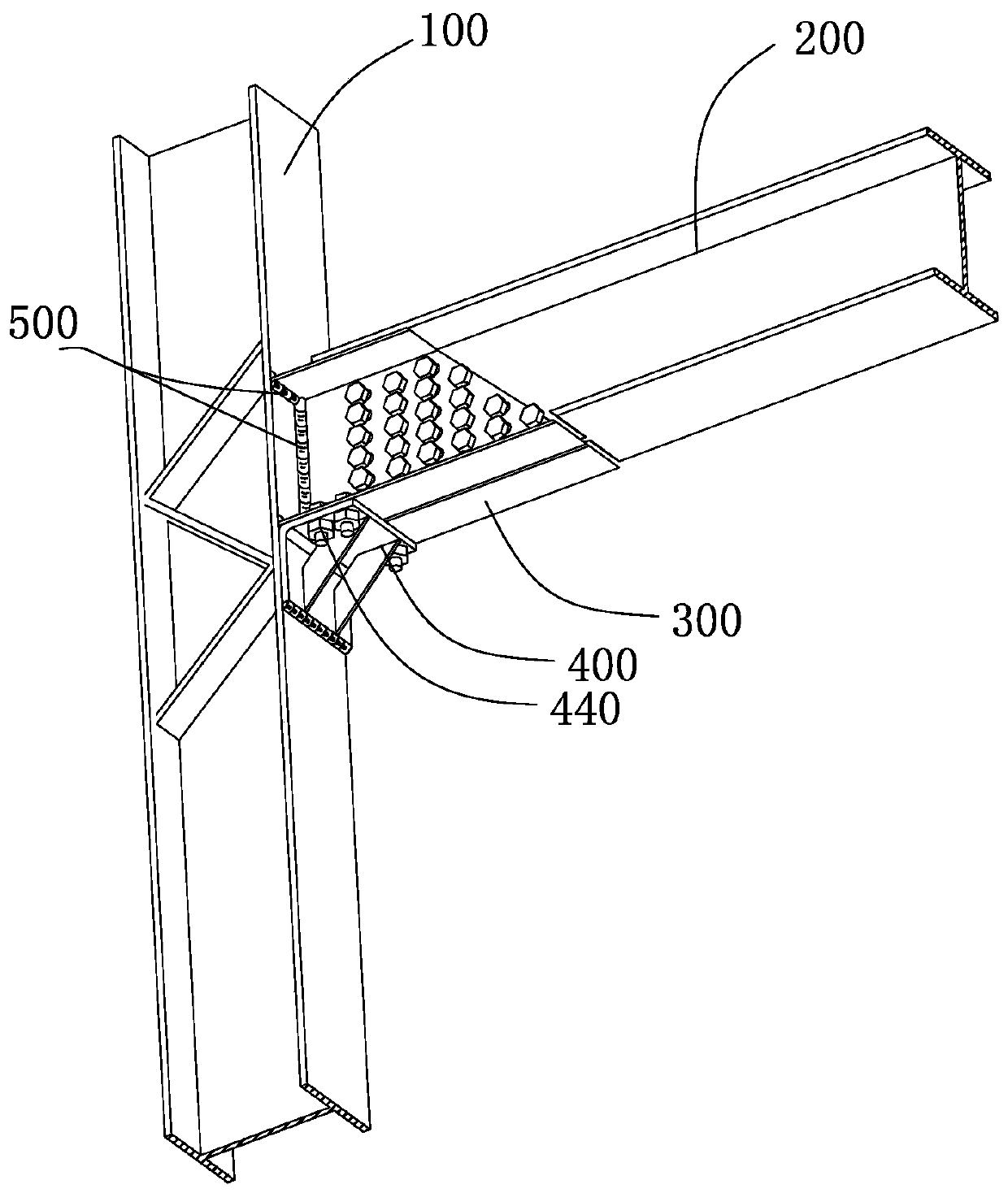

[0037] The anti-seismic joints of steel structures used in prefabricated buildings involve the design of joints at the intersecting parts of steel beams and steel columns. Wherein, the steel column in the present invention is described by taking an I-shaped steel column as an example, and the steel beam is described by taking an I-shaped steel beam as an example.

[0038] The steel column 100 is formed by cutting and welding a steel plate with a thickness of 2-5 cm. After welding, the whole is an H-shaped structure composed of a column flange 110 and a column web 120, which is a weldment.

[0039] The steel beam 200 is formed by cutting and welding steel plates with a thickness of 1-3 cm. After welding, the H-shape formed by the beam flange 210 and the beam web 220 is a weldment.

[0040] Steel columns and steel beams, as different components, are fully welded and connected in the factory workshop, and then transported to the construction site for prefabricated construction wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com