Slide valve air valve type gasoline engine with opposed pistons

A technology of opposing pistons and gasoline engines, applied in the direction of internal combustion piston engines, cylinders, cylinder heads, etc., can solve problems such as fuel short circuit and insufficient ventilation, and achieve the effects of suppressing knocking, stabilizing and accelerating the combustion process, and optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

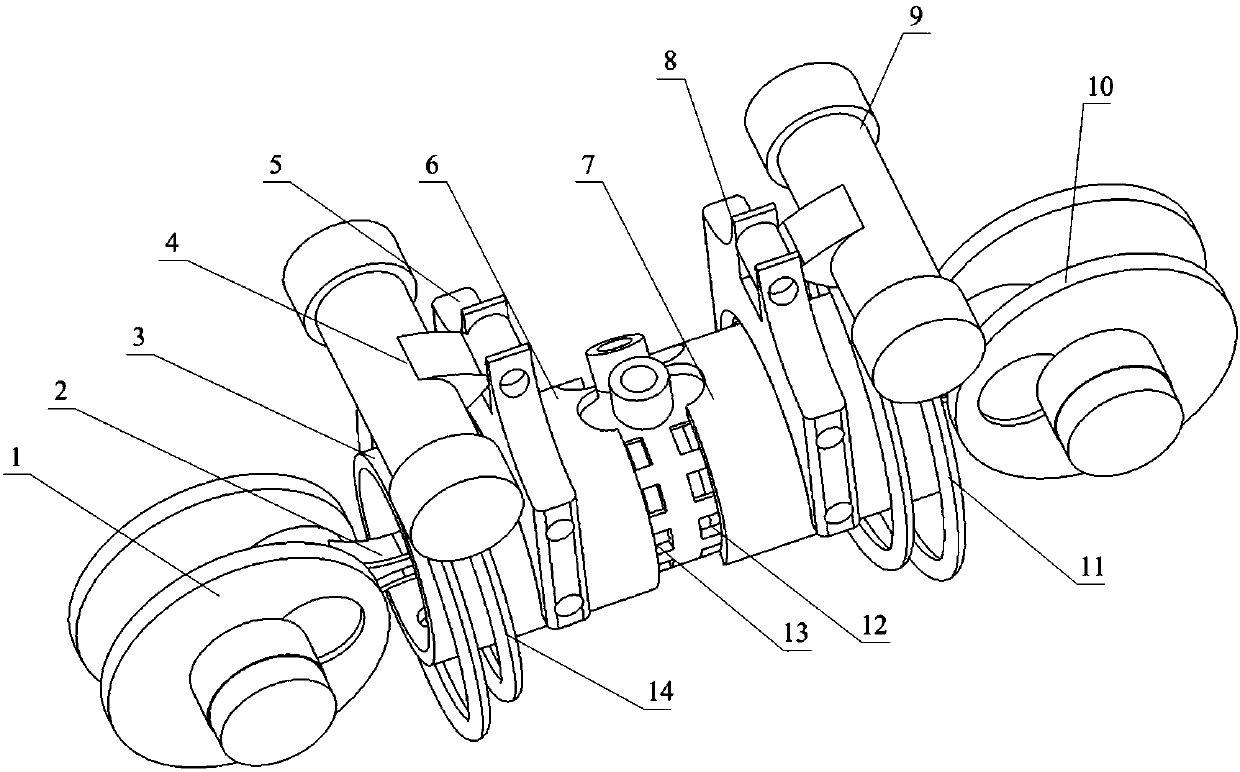

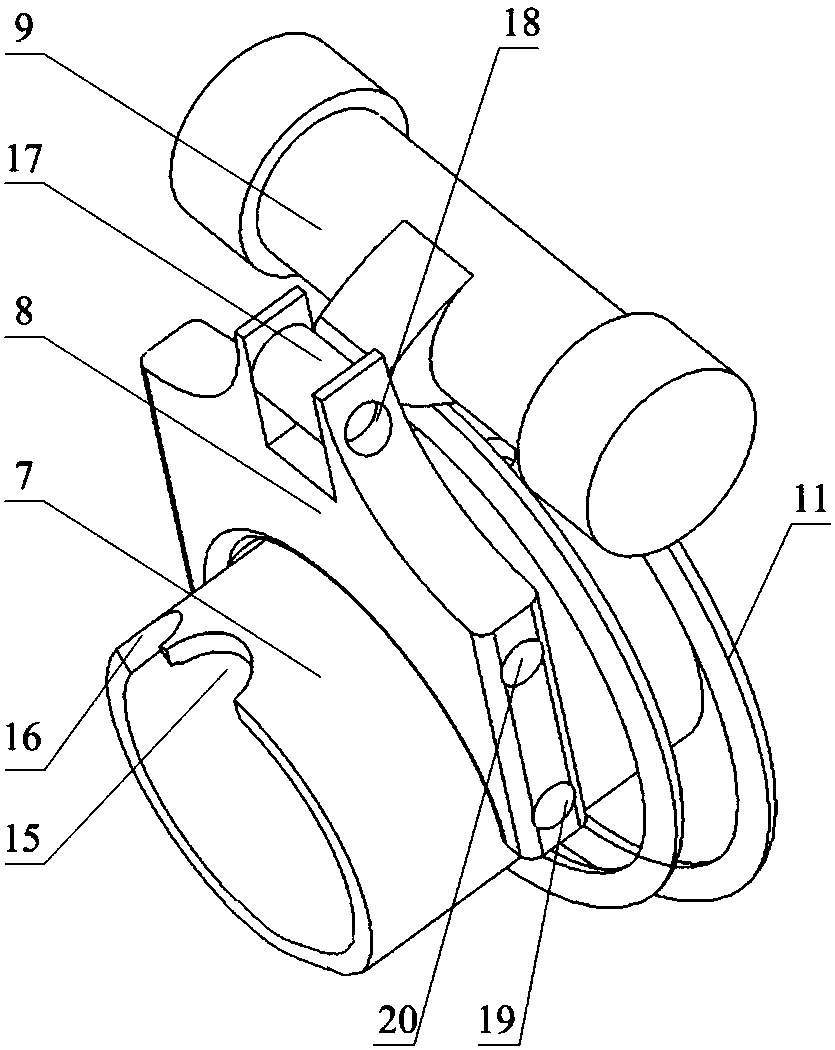

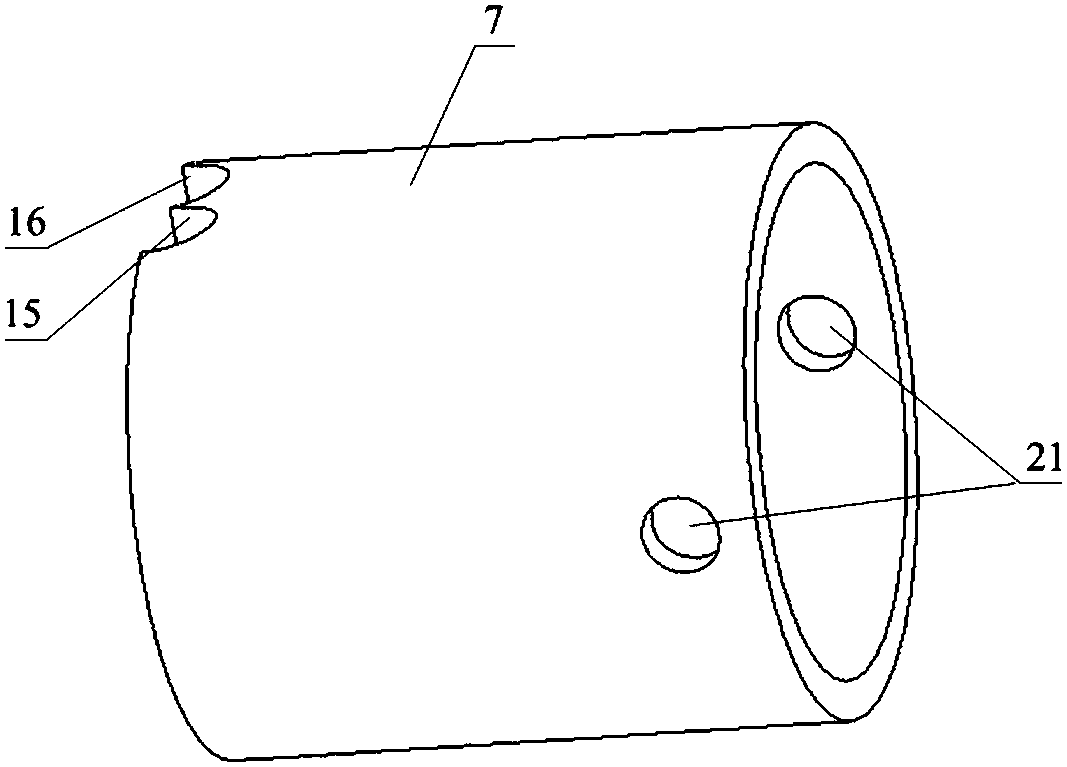

[0024] see Figure 1-Figure 6 The present invention provides a sliding valve valve type opposed-piston gasoline engine, comprising a cylinder liner 3, an intake side sliding valve valve type valve mechanism, an exhaust side sliding valve valve type valve mechanism and an opposed crank connecting rod mechanism, It is characterized in that, the middle of the side wall of the cylinder liner 3 is provided with a spark plug mounting hole 22 and an injector mounting hole 23, the spark plug is mounted in the spark plug mounting hole 22, and the fuel injector is mounted in the fuel injector mounting hole 23; the The spark plug mounting hole 22 and the injector mounting hole 23 are located on the same cross section of the cylinder li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com